- Product Details

- {{item.text}}

Quick Details

-

Maximum Working Pressure:

-

More than 0.6Mpa

-

Weight:

-

1 KG

-

Dimension(L*W*H):

-

520*124*60mm or customized

-

Material:

-

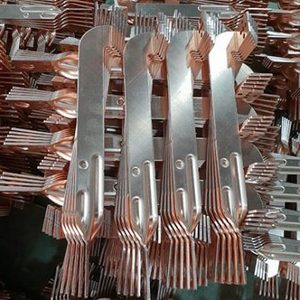

Aluminum or Copper

-

Surface Finish:

-

Baking finish,painting

-

Main technique:

-

Extrusion,CNC machining

-

Bonding technique:

-

Vacuum brazing

-

Tube Qty:

-

10,12,18 or customized

-

Fluid:

-

Water or suitable coolant

-

Application:

-

Radiator for computer server,computer case,beauty/medical equipment

-

Compressive strength:

-

More than 0.6Mpa

-

Product name:

-

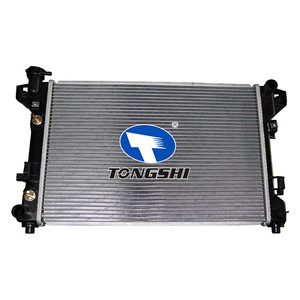

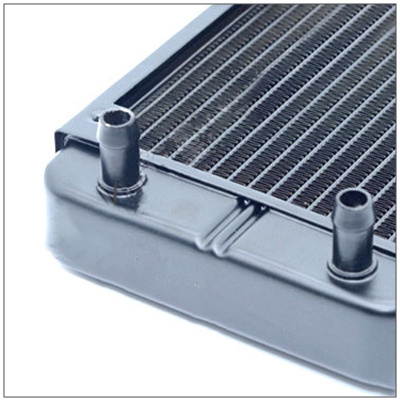

aluminium radiating plate radiators water radiator

Quick Details

-

Structure:

-

Tube Heat Exchanger

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

M-stirling or OEM

-

Maximum Working Pressure:

-

More than 0.6Mpa

-

Weight:

-

1 KG

-

Dimension(L*W*H):

-

520*124*60mm or customized

-

Material:

-

Aluminum or Copper

-

Surface Finish:

-

Baking finish,painting

-

Main technique:

-

Extrusion,CNC machining

-

Bonding technique:

-

Vacuum brazing

-

Tube Qty:

-

10,12,18 or customized

-

Fluid:

-

Water or suitable coolant

-

Application:

-

Radiator for computer server,computer case,beauty/medical equipment

-

Compressive strength:

-

More than 0.6Mpa

-

Product name:

-

aluminium radiating plate radiators water radiator

aluminium radiating plate radiators water radiator

Custom Design,Lighter,Clean,Stronger,

Flexible,Competitive price,Better heat transfer performance.

Flexible,Competitive price,Better heat transfer performance.

|

PRODUCT SPECIFICATION FOR WATER RADIATOR

|

|

|

||

|

NO.

|

ITEM DESCRIPTION

|

CONTENT

|

||

|

1

|

Material

|

Aluminum or copper

|

||

|

2

|

Dimension L*W*H

|

520*124*60mm or customized

|

||

|

3

|

Joining

Method

|

Brazing, welding or other suitable techniques

|

||

|

4

|

Manufacturing technique

|

CNC machining, extrusion or other suitable processes

|

||

|

5

|

Recommended Coolants

|

Water,Ethylene Glycol,Ethyl Alcohol

|

||

|

6

|

Surface finish

|

Baking finish,painting

|

||

|

7

|

Place of Origin

|

China

|

||

|

8

|

Packing way

|

To be packed in carton box or plywood case with films protection

|

||

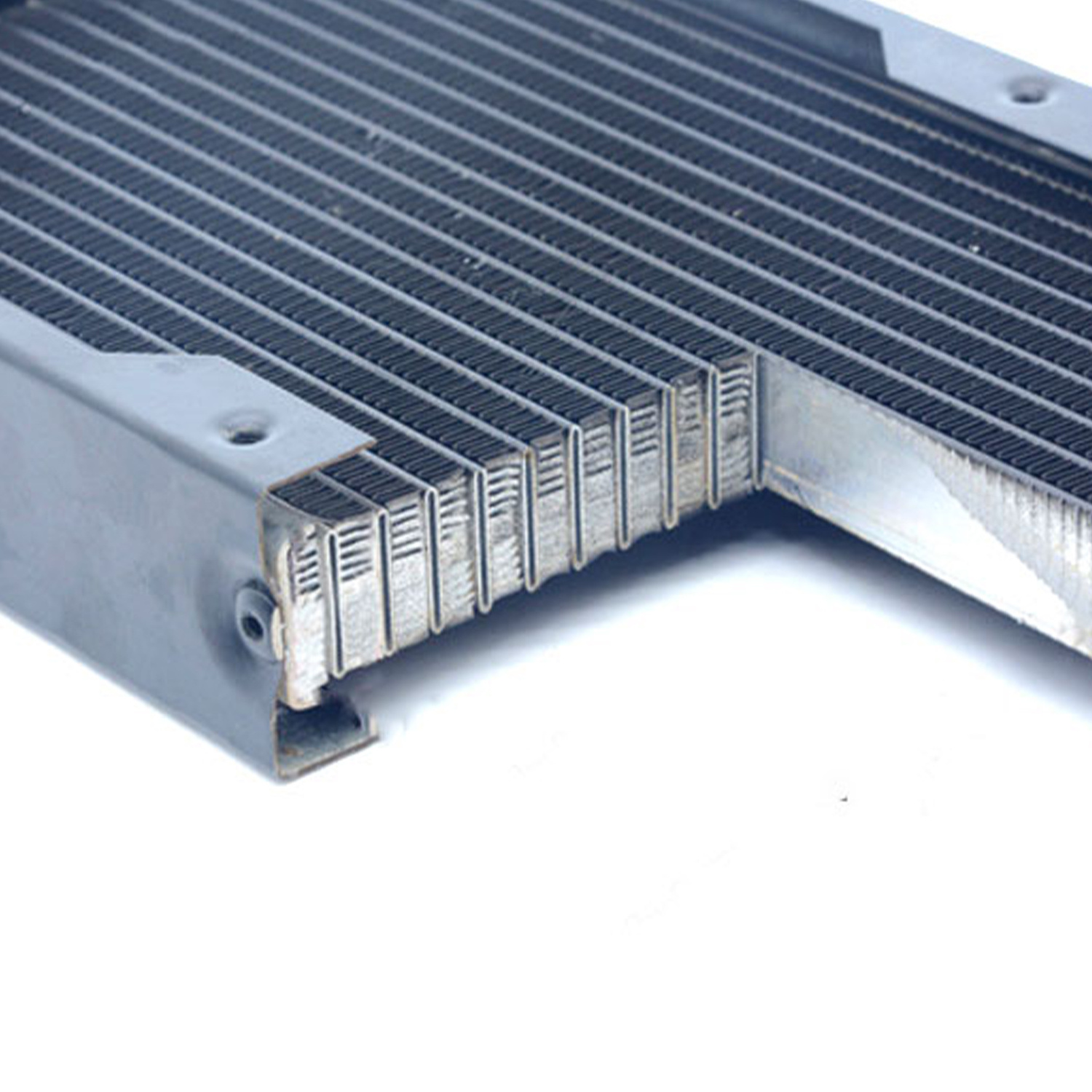

Specifications

Very useful water cooling radiator for computer.

5 types for you to choose from, including 90mm, 120mm, 240mm, 360mm, 480mm.

With threaded port, you need to buy proper pipe joint for connection.

Comes with aluminum pipes, can dissipate heat more fast.

Item Name: Water Cooling Radiator

5 types for you to choose from, including 90mm, 120mm, 240mm, 360mm, 480mm.

With threaded port, you need to buy proper pipe joint for connection.

Comes with aluminum pipes, can dissipate heat more fast.

Item Name: Water Cooling Radiator

A series of available Sizes or Specifications for Cold Plates

►90mm Size(L x W x T): 13.5cm x 9.8cm x 3.2cm/5.32" x 3.85" x 1.26" (Approx.)

►120mm Size(L x W x T): 15.7cm x 12cm x 3.2cm/6.18" x 4.72" x 1.26" (Approx.)

►240mm Size(L x W x T): 27.5cm x 12cm x 3.2cm/10.83" x 4.72" x 1.26" (Approx.)

►360mm Size(L x W x T): 39.3cm x 12cm x 3.2cm/15.47" x 4.72" x 1.26" (Approx.)

►240mm Size(L x W x T): 27.5cm x 12cm x 3.2cm/10.83" x 4.72" x 1.26" (Approx.)

►360mm Size(L x W x T): 39.3cm x 12cm x 3.2cm/15.47" x 4.72" x 1.26" (Approx.)

Structure of fins

Installation method

1. Fan installation:

take the screws of the fan through the mounting holes,and tighten it on the threaded holes of the radiator (pay attention to the depth of the screw, do not let the screw break the radiator and lead to leakage).

2. Radiator installation:

After fixing the fan to the radiator, use small screws to fix the radiator on the computer case.

Liquid Cooling Plate

Heat Exchanger Material and Parts

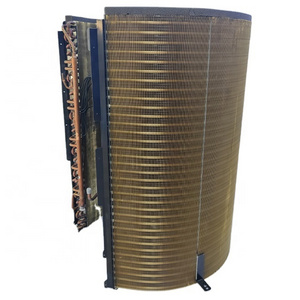

Heat Exchanger

Heat Sink

Nanjing Mstirling-your ideal partner for thermal management and metal fabrication solutions

✅ Since 2008, Nanjing

Mstirling

has been focusing on thermal management field. Our capabilities cover a wide range that provide you one-stop solution quicker and easier. Our main capabilities include:

◇ Vacuum Brazing and Controlled Atmosphere Brazing

◇ CNC machining

◇ Welding

◇ Aluminum extrusion

◇ Aluminum die casting

◇ Sheet metal fabrication covering laser cutting, stamping, drawing and bending

◇ Surface coating

✅We emphasis prototype process. we use our vast experience in fluid dynamics, thermal performance, and material compatibility to optimize your design. To perform advanced thermal analysis, our engineers use simulation software like CFD, 6 Sigma. In addition

to providing expert thermal and mechanical design engineering, we ensure that your products fit DFM concept so that your products can be built to your exact specifications as well as meet your delivery schedule.

✅ We see quality aspects from manufacturing viewpoints. Focusing more on monitoring and minimizing process variable to keep stable quality level. Delivered products are performed 100% inspection or testing. Less worries of quality risk and loss

✅ Our lean manufacturing and continuous improvement program aim at eliminating all wastes that do not add values. Our customers do not need to pay for wastes. The cost will be more and more competitive that help grow up your business and build your success.

◇ Vacuum Brazing and Controlled Atmosphere Brazing

◇ CNC machining

◇ Welding

◇ Aluminum extrusion

◇ Aluminum die casting

◇ Sheet metal fabrication covering laser cutting, stamping, drawing and bending

◇ Surface coating

✅We emphasis prototype process. we use our vast experience in fluid dynamics, thermal performance, and material compatibility to optimize your design. To perform advanced thermal analysis, our engineers use simulation software like CFD, 6 Sigma. In addition

to providing expert thermal and mechanical design engineering, we ensure that your products fit DFM concept so that your products can be built to your exact specifications as well as meet your delivery schedule.

✅ We see quality aspects from manufacturing viewpoints. Focusing more on monitoring and minimizing process variable to keep stable quality level. Delivered products are performed 100% inspection or testing. Less worries of quality risk and loss

✅ Our lean manufacturing and continuous improvement program aim at eliminating all wastes that do not add values. Our customers do not need to pay for wastes. The cost will be more and more competitive that help grow up your business and build your success.

Vacuum Brazing Furnace

CNC Machine

Meeting Discussion with Customers

ISO9001 Certified

100% tested or Inspected

Thermal Simulation Analysis

Hot Searches