- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Dingbo

-

Model Number:

-

DBRG

-

Power:

-

5.5KW

-

Voltage:

-

380V 50Hz 3phases(customized)

-

Dimension(L*W*H):

-

L*W*H)

-

Weight:

-

5 Tons

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Downspout Pipe and Elbow Gutter Machine Roll Forming Machine

-

Raw material:

-

Color Steel Sheet

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Roller driven type:

-

Chain transmission

-

Roller material:

-

45# Forged Steel

-

Control system:

-

PLC

-

Color:

-

Customers Requirement

-

Certification:

-

CE ISO SGS

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

10-15m/min

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Dingbo

-

Model Number:

-

DBRG

-

Power:

-

5.5KW

-

Voltage:

-

380V 50Hz 3phases(customized)

-

Dimension(L*W*H):

-

L*W*H)

-

Weight:

-

5 Tons

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Downspout Pipe and Elbow Gutter Machine Roll Forming Machine

-

Raw material:

-

Color Steel Sheet

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Roller driven type:

-

Chain transmission

-

Roller material:

-

45# Forged Steel

-

Control system:

-

PLC

-

Color:

-

Customers Requirement

-

Certification:

-

CE ISO SGS

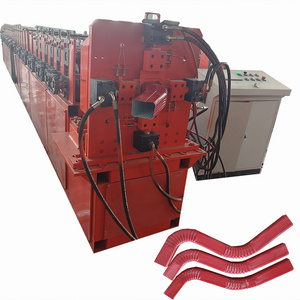

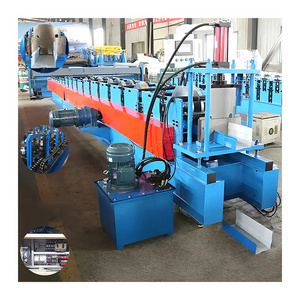

Downspout Pipe and Elbow Gutter Machine Roll Forming Machine

Main features

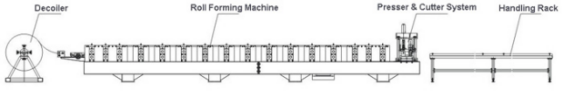

Color steel rain gutter roll forming machine includes a decoiler, sheet guiding equipment, roll forming system, cutting equipment, hydraulic station, electric controlling system and product supporter.Curving pipe forming machine is the complementary equipment for down pipe forming machine. It can make curve for down pipe to meet the requirement of practical engineering projects.

Working flow

Main parameters

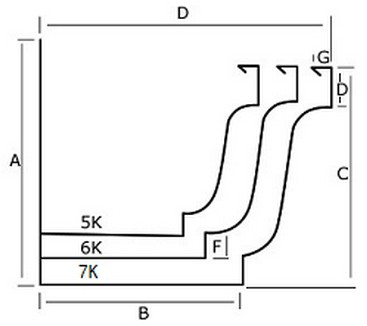

1. Suitable to process : Color steel plate , Aluminum

2. F orming station: D epend on profile drawing

3. Forming speed of round downspout roll forming machine: 0- 12m/min

4. Voltage: 380 V, 3 Phase 50Hz ( or depend on customer’s requirement )

5. Dimension of machine: Ab out 12000mm*1100mm*1200mm

6. Main motor power: 5 .5Kw

7. Machine wight: About 5 Ton

8. Material of Axis: High grade 45# steel

9. Diameter of Axis: φ75mm

10. Material of Roller: High grade 45#

11. Material of Machine Frame: A3 Steel, thickness 18mm

12. Electrical Control: PLC Frequency Control System with touch screen

13. PLC: PANASONIC Brand

14. Encoder: OMRON Brand

15. Frequency converter : PANASONIC Brand

Machine components

|

S.N |

Equipment name |

Quantity |

|

1. |

5 T manual un-coiler |

1 set |

|

2. |

Feeding and leveling device |

1 set |

|

5. |

Main roll forming machine |

1 set |

|

6. |

Hydraulic station |

1 set |

|

7. |

Control system (including control box) |

1 set |

|

8. |

Out tables |

2 sets |

|

9. |

Spare parts |

1 package |

1.Advanced machinery, well trained workers.

2.More than 20 years experience in roll forming machine industry.

3.Unique designed, good Germany quality, competitive China price.

4.Full process of roll forming machine solution.

5.Shipment arrangement available.

6.After-sales services for overseas installation and commissioning