- Product Details

- {{item.text}}

Quick Details

-

Material:

-

/, FRP,SMC,GRP

-

Weight:

-

120

-

Size:

-

100*100*100

-

Power:

-

/

-

Productivity:

-

/

-

Weight (KG):

-

120 kg

-

Application:

-

Drinking Water

-

Certification:

-

ISO9001

-

Capacity:

-

0.125m3-5000m3

-

Panel Size:

-

1*2m,1*1m,1*0.5m,0.5*0.5m

-

Name:

-

5000 litre fiberglass drinking water storage tank

-

Panel thickness:

-

6mm-24mm

-

Technology:

-

Molding

-

Type:

-

Modular design

-

Item:

-

Square Water Storage Tank

Quick Details

-

Core Components:

-

panel

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GRAD

-

Material:

-

/, FRP,SMC,GRP

-

Weight:

-

120

-

Size:

-

100*100*100

-

Power:

-

/

-

Productivity:

-

/

-

Weight (KG):

-

120 kg

-

Application:

-

Drinking Water

-

Certification:

-

ISO9001

-

Capacity:

-

0.125m3-5000m3

-

Panel Size:

-

1*2m,1*1m,1*0.5m,0.5*0.5m

-

Name:

-

5000 litre fiberglass drinking water storage tank

-

Panel thickness:

-

6mm-24mm

-

Technology:

-

Molding

-

Type:

-

Modular design

-

Item:

-

Square Water Storage Tank

Product Description

Square Water Storage Tank Introudction

FRP water tank is made of fiberglass reinforced plastics which is divided in FRP Modular Type and SMC combination type. The major advantage is light weight, anti-rusted, non-leakage, long durable time and easy to clean. It’s widely used in hotel, school, hospital and coal mine enterprise.

Square Water Storage Tank Advantages

(1) Strong resistance to corrosion

(2) Reasonable structure design

(3) All welded on-site combination. High strength, good sealing,

prevent secondary pollution of water quality

(4) Light weight, that is one half of ordinary steel plate water tank

(5) Easy to install

(6) Clean, bright, beautiful appearance

Square Water Storage Tank Applications

The water tank has been widely used in residential buildings, hotels, office buildings, R&D buildings,schools, malls, restaurants and other public facilities as well as places with high requirements for water quality, such as hospitals and food processing plants.

FRP water tank is made of fiberglass reinforced plastics which is divided in FRP Modular Type and SMC combination type. The major advantage is light weight, anti-rusted, non-leakage, long durable time and easy to clean. It’s widely used in hotel, school, hospital and coal mine enterprise.

Square Water Storage Tank Advantages

(1) Strong resistance to corrosion

(2) Reasonable structure design

(3) All welded on-site combination. High strength, good sealing,

prevent secondary pollution of water quality

(4) Light weight, that is one half of ordinary steel plate water tank

(5) Easy to install

(6) Clean, bright, beautiful appearance

Square Water Storage Tank Applications

The water tank has been widely used in residential buildings, hotels, office buildings, R&D buildings,schools, malls, restaurants and other public facilities as well as places with high requirements for water quality, such as hospitals and food processing plants.

Square Water Storage Tank Assembly

Step 1. Install steel footings on leveled concrete foundations.

Step 2. Align GRP panels to be pre-assembled.

Step 3. Place rubber sealant from ready-to-use roll between panels.

Step 4. Connect panels with bolts and nuts.

Step 5. Position bottom panel sections, and finish up base of tank.

Step 6. Position three sides of the tank.

Step 7. Position and fix top panels and if required, top support pipes and plates.

Step 8. Install reinforcement if required.

Step 9. Close up the tank with the fourth side.

Step 10. Finish the internal or external reinforcement.

Step 11. Fill and test.

Step 1. Install steel footings on leveled concrete foundations.

Step 2. Align GRP panels to be pre-assembled.

Step 3. Place rubber sealant from ready-to-use roll between panels.

Step 4. Connect panels with bolts and nuts.

Step 5. Position bottom panel sections, and finish up base of tank.

Step 6. Position three sides of the tank.

Step 7. Position and fix top panels and if required, top support pipes and plates.

Step 8. Install reinforcement if required.

Step 9. Close up the tank with the fourth side.

Step 10. Finish the internal or external reinforcement.

Step 11. Fill and test.

Specification

|

parameter

|

GRAD water tank

|

Other water tank

|

|

Tensile strength(Mpa)

|

≥60

|

≥60

|

|

Bending strength(Mpa)

|

≥120

|

≥100

|

|

Bending modulus(Gpa)

|

≥7.0

|

-

|

|

Pap hardness

|

≥60

|

≥60

|

|

Bibulous rate(%)

|

≤0.5

|

≤1.0

|

|

Glass fiber content(%)

|

≥27

|

≥25

|

|

Maximum distortion of side wall

|

≤0.5%

|

≤0.5%

|

|

distortion of the bottom

|

≤8mm.

|

≤8mm.

|

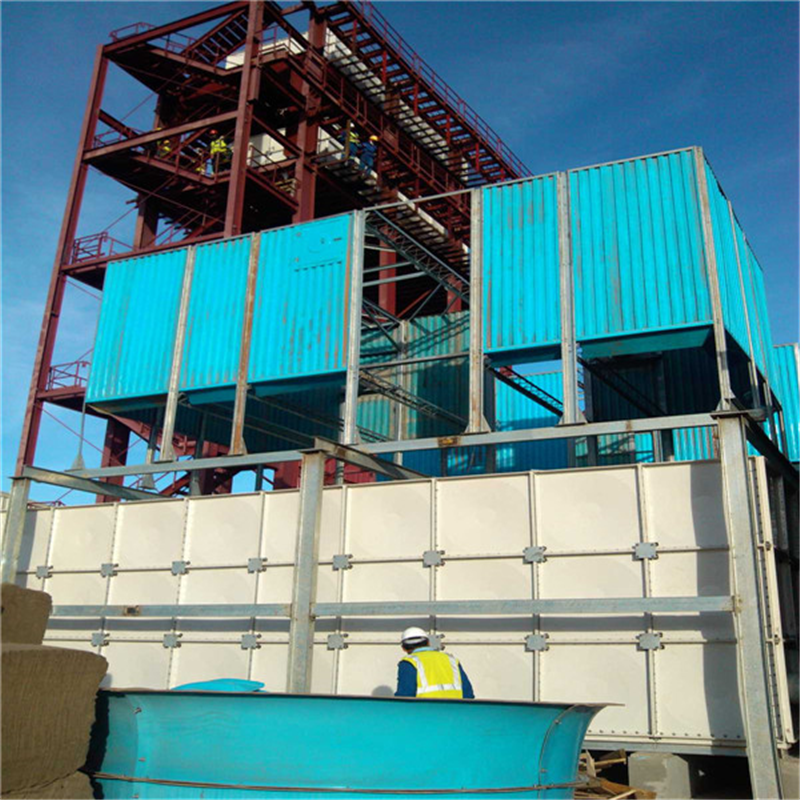

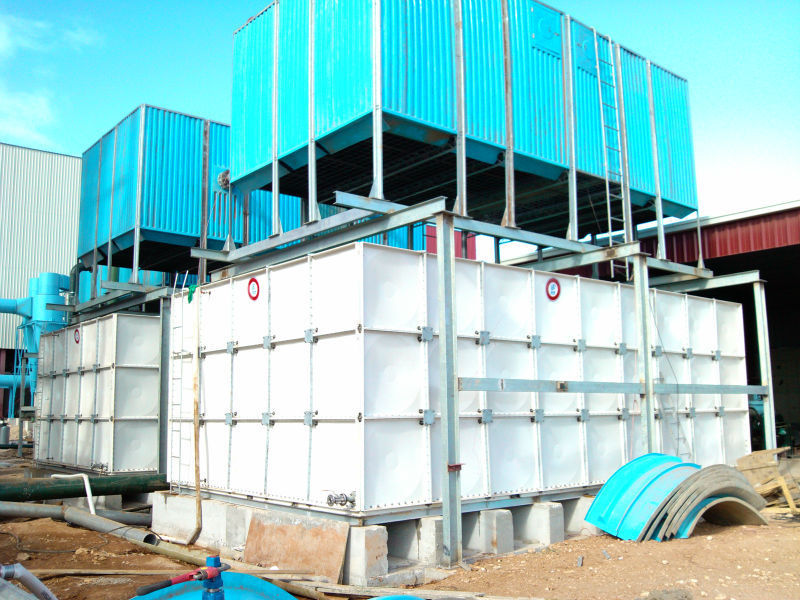

Project show

GRAD sales network covers over 100 countries and regions like America, Australia Indonesia, Malaysia, UAE, Thailand, Nigeria etc and has established branch company in USA, and set up offices in Cambodia and Thailand to make overall layout of global market.

Project in South Africa

Project in Dubai

Project in

Bengal

Project in Samoa

Project in Equatorial Guinea

Project in Columbia

Hot Searches