Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LIANSHUN

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

12m*1.5m*2.5m

-

Power (kW):

-

22

-

Weight:

-

18000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

PE PP PVC single wall corrugated tube production line

-

Raw material:

-

PP PE Granules

-

Product Type:

-

single wall corrugated tube

-

Motor:

-

Germany SIEMENS Motor

-

Inverter:

-

ABB Brand

-

Temperature controller:

-

Japan Omron

-

Pipe diameter range:

-

9-200mm

-

Material:

-

stainless steel 304

-

Color:

-

Selectable

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw diameter (mm):

-

50 mm

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LIANSHUN

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

12m*1.5m*2.5m

-

Power (kW):

-

22

-

Weight:

-

18000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

PE PP PVC single wall corrugated tube production line

-

Raw material:

-

PP PE Granules

-

Product Type:

-

single wall corrugated tube

-

Motor:

-

Germany SIEMENS Motor

-

Inverter:

-

ABB Brand

-

Temperature controller:

-

Japan Omron

-

Pipe diameter range:

-

9-200mm

-

Material:

-

stainless steel 304

-

Color:

-

Selectable

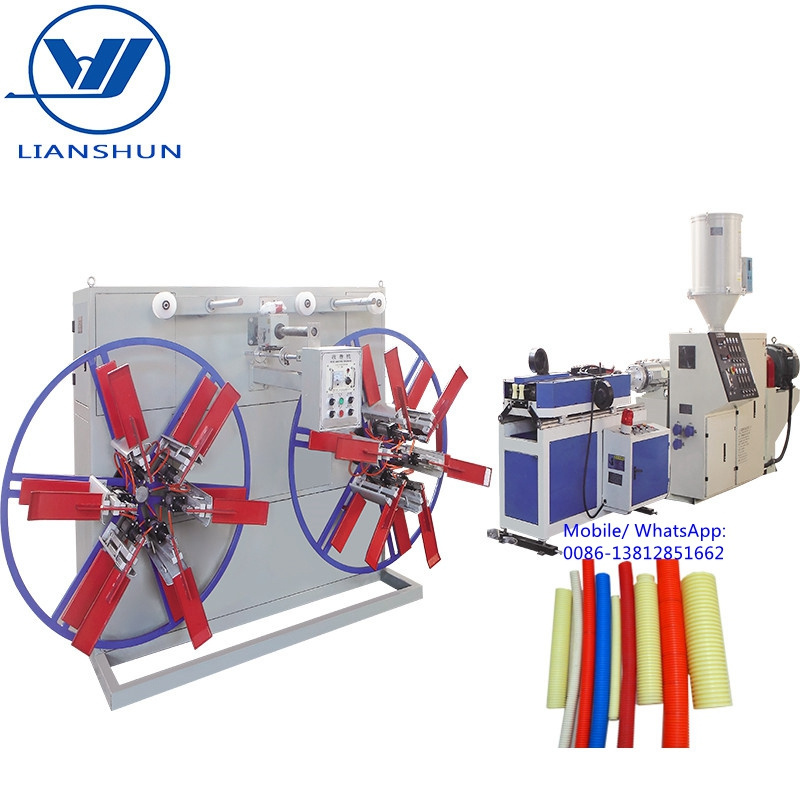

PE PP PVC single wall corrugated tube production line

HDPE PE PP PVC Single Wall Corrugated Tube Making Machine

Plastic Corrugated Pipe Making Machine

Description of single wall corrugated tube making machine:

Corrugated tube forming machine has closed structure, and we can also provide vacuum forming.Forming mould move back and forth in a closed and integrally tunnel. Forming tunnel is sandwich design and cooling the mould forcely by cooling the water.Molding strip is made of carbide steel, so it is corrosion resistant.

Single-wall corrugated tube machine was developed by our factory. It adopts gears to run modules and templates so as to realize water circulating cooling and air cooling of the products, which ensures high-speed molding, even corrugation, smooth inner and outer pipe wall. These corrugated pipes are especially used in wires conduit pipe.

The single wall corrugated tube are widely used in fields of auto wire, electric thread-passing pipes, circuit of machine tool, protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine, etc.

Process flow of single wall corrugated tube making machine:

Raw material+master batches→mixing → vacuum feeding → material dryness → single screw extruder → extrusion mould → corrugated forming machine → meter measure → double winder → finished product inspecting&packing

Main Technical Parameters:

|

Model

|

SJ45

|

SJ65

|

|

Pipe diameter scope (mm)

|

12-50 mm

|

50-110 mm

|

|

The number of modules (pairs)

|

42

|

50

|

|

Line speed (m/min)

|

3-12

|

1-6

|

|

Modules cooling

|

Air-cooled

|

Air-cooled

|

|

Pipe cooling

|

Air-cooled

|

Air-cooled

|

|

Air-cooling power (kw)

|

0.5*3

|

0.5*4

|

|

Winding power (kw)

|

10-18.5

|

10-35

|

|

Auxiliary power (kw)

|

2.2

|

5

|

|

Weight (kg)

|

4500

|

5500

|

HDPE PE PP PVC Single Wall Corrugated Tube Making Machine

Plastic PE Corrugated Pipe Making Machines

Contact Mobile/ WhatsApp: +86-13812851662.

1. Turn key project

2. Technical documents

We will offer you all necessary documents, e.g. general layout plan, water scheme, electrical diagram and user manual after the contract is executed.

3.Arrangement for inspection, installation and testing work

We will inspect and test the machine in our factory first before shipping the machine. Customers are welcome to come and check the working machine, until the machine produces the exact products as customers requirements, and learn operation in our factory.

After the machine is delivered to customer’s factory, we will send one or two technicians to customer’s factory for on-site installation and commissioning of the whole machine line. Meanwhile, technicians will give free training lessons to workers in customer’s factory.

4.The guarantee period of the whole machine is 15 months.

5.Technical support from our factory is free of charge for all the life; quick response to any questions from customers.

Why choose us:

1. Low cost : all the machines ,we make them by ourself to reduce the cost for our customers.

2. Genuine product with excellent quality : we choose our material very strict, all the material come to our factory must pass the quality test substandard goods are returned to the supplier.

3. Engerneers available to serve oversea.

4. Quick delivery: the company provide just in time delivery with its streamlined supply chain.

5. Cost saving: we take strong attention to every detail in the manufacturing process,the quality control in our factory is very strict, all defective semi-manufactures must be treated again or reject. all the machine must be checked out ,then deivered to our customer. all about that pushing up the price, what we want to do is give our customer a good quality product with stable working and long lived.

1.Q: Are you an industry manufacture factory or a foreign trade company?

A: We are an industrial manufacture factory of plastic extrusion machinery and auxiliary equipment, which locates in Zhangjiagang city, China.

2.Q: Payment term:

A: Loading Port: Shanghai by sea or by train.

T/T, L/C, West Union, or Cash, etc.

3.Q: Do you have any other services for your products?

A: We have rich experience in manufacturing plastic machinery, so we can manufacture various machines according to customers’ requirement.

4. Q:How do you make the quotation for clients?

A:The price depends on quality and performance but the clients should be satisfied first.

Jiangsu Lianshun Machinery CO.,Ltd. is located in Zhangjiagang city, Jiangsu province, China. It’s a professional manufacturer specializing in research&development and producing plastic extrusion machinery. The main products include: plastic pipe extrusion lines, plastic profile production lines, plastic sheet extrusion lines, WPC board and profile extrusion line, PET bottle flakes washing recycling lines, PP/PE film washing recycling lines, PVC/PP/ PE pelletizing lines and auxiliary machinery (mixer unit, crusher and shredder, belling machine, etc.)

We have enjoyed great prestige from our customers both at home and abroad with good products quality and considerate service.We exported our products to many countries and regions all over the world, such as the Mid-East, Africa, Southeast Asia, South America, Europe,etc.

We sincerely hope to cooperate with customers from all over the world.

If you are interested in PE PP PVC single wall corrugated tube making machine, please contact us, thanks!

Our company is near Shainghai City, about 130km. Welcome you to visit our factory anytime!