- Product Details

- {{item.text}}

Quick Details

-

Operating Temperature(℃):

-

-30 - 85

-

Storage Temperature(℃):

-

-30 - 65

-

Place of Origin:

-

Guangdong, China

-

Power Dissipation:

-

10W

-

Continuous Forward Current:

-

700mA

-

Lens:

-

Water Clear,Silicone,Molding

-

Product Description:

-

High Thermal Conductivity Ceramics

-

Input & Output:

-

color controlled by circuit

Quick Details

-

Color Temperature(CCT):

-

RGBA

-

Warranty(Year):

-

2-Year

-

Power:

-

10W

-

Operating Temperature(℃):

-

-30 - 85

-

Storage Temperature(℃):

-

-30 - 65

-

Place of Origin:

-

Guangdong, China

-

Power Dissipation:

-

10W

-

Continuous Forward Current:

-

700mA

-

Lens:

-

Water Clear,Silicone,Molding

-

Product Description:

-

High Thermal Conductivity Ceramics

-

Input & Output:

-

color controlled by circuit

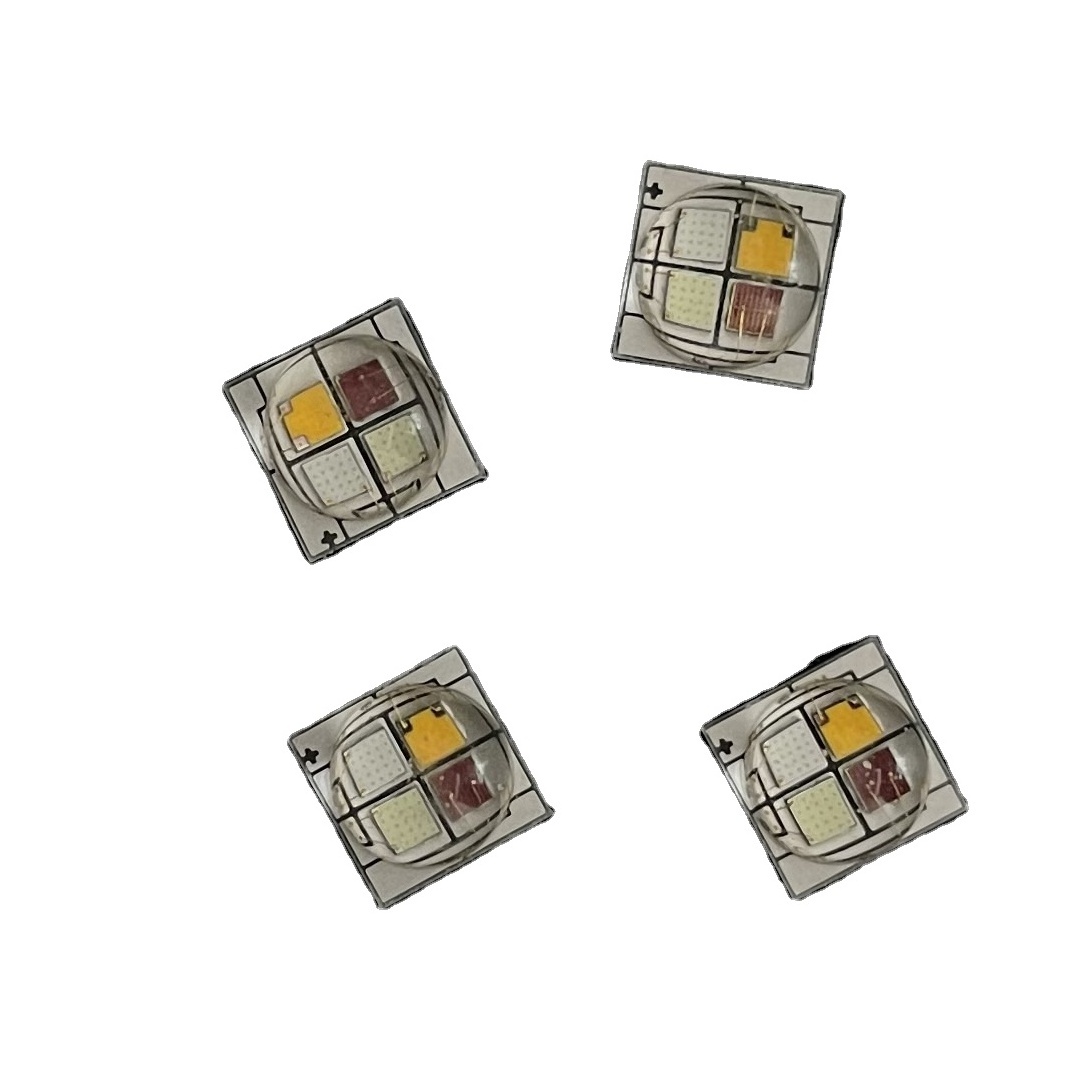

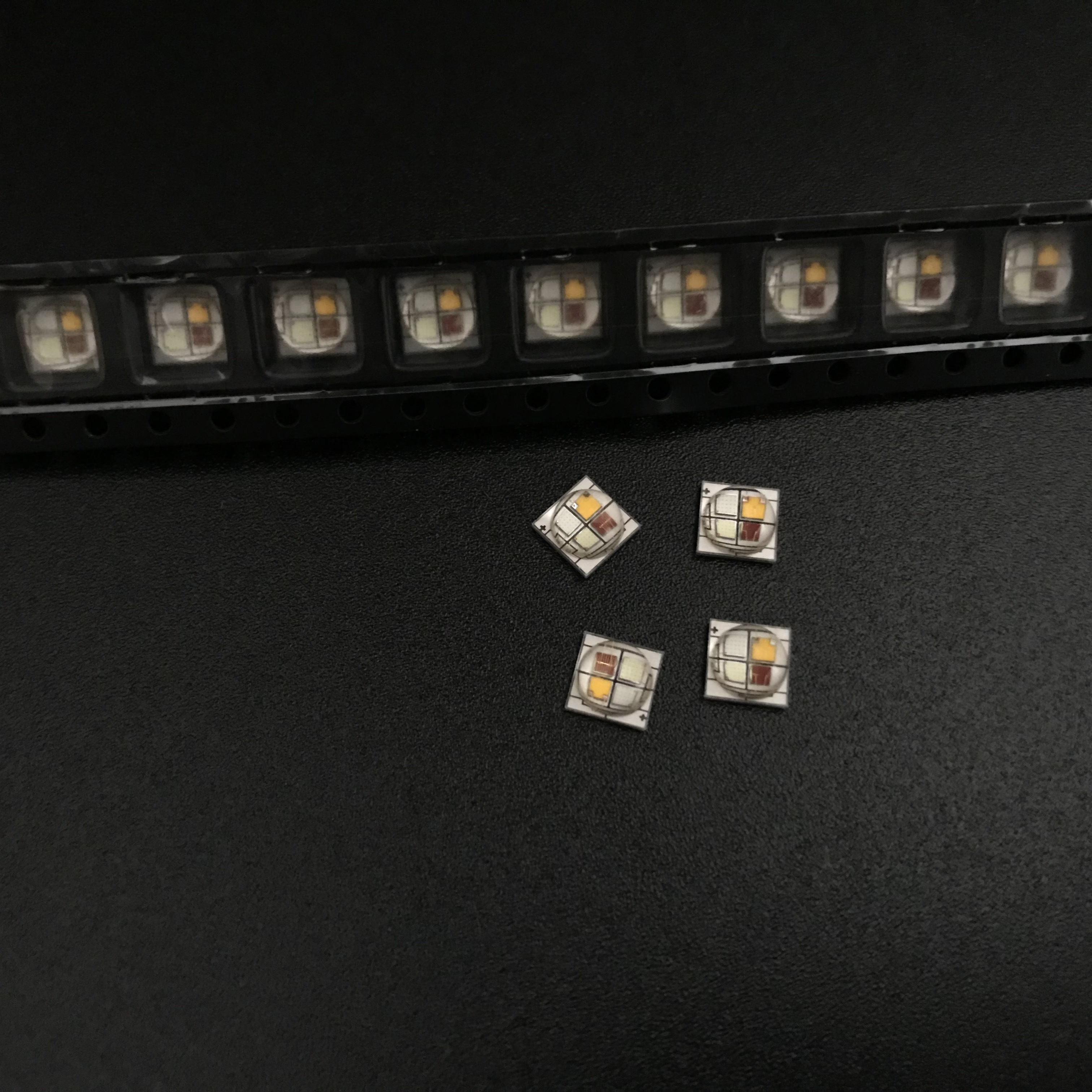

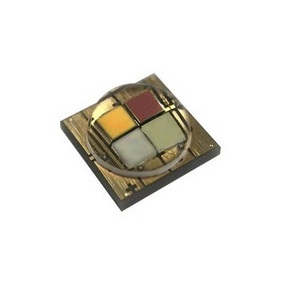

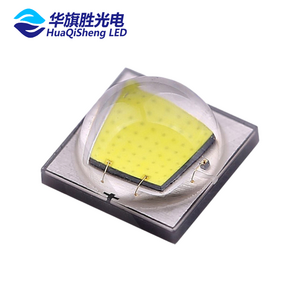

Hot Sell 10W 5050 4IN1 Ceramic-LED High Power RGB Amber Led Didoes

Product Description

Electrical/Optical Characteristics (At Ta=25°C)

| RGBA LED | Standard Values | |||

| COLOR |

Dominant Wavelength /nm |

If(mA) |

Forward Voltage /V |

Luminous Flux /lm |

| Red | 615-635nm | 700 | 1.8-2.8 | 95-122 |

| Green | 515-535nm | 700 | 2.8-3.8 | 210-260 |

| Blue | 450-465nm | 700 | 2.8-3.8 | 35-51.7 |

| Amber | 585-605nm | 700 | 1.8-2.8 | 50-67.2 |

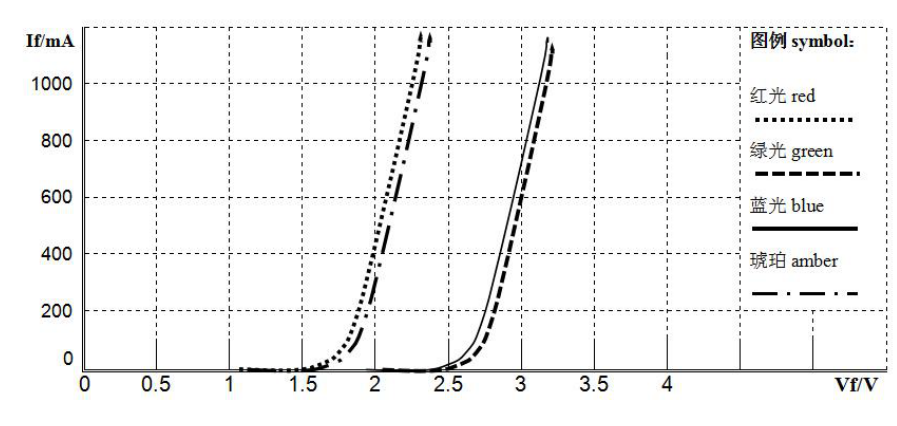

Current-Voltage Curves

(

At Ta=25°C

)

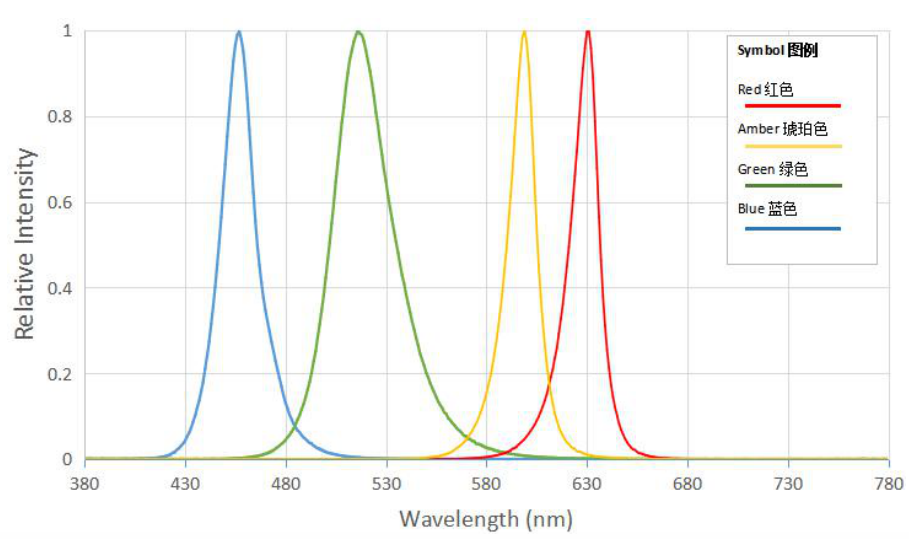

Spectrum Distribution (At Ta=25°C)

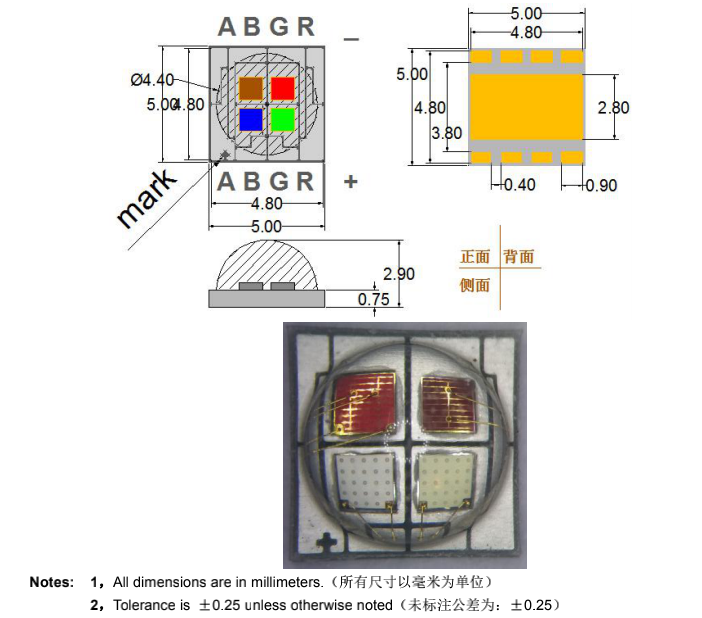

Package Dimensions & Product Picture

Packaging & Shipping

Instruction

1. Reserve:

It should be reserved in dry cabinets in case of moisture. The temperature for reserve

is 25

℃

±3

℃

, and the humidity is >40% but <60%.

2. How to handle after removing the tubes:

When sticking the tin, the pasted components separated from the surface of lens may

affect lighting efficiency to cause illuminating degradation. Therefore, it must be

complied as below:

A. The time which products are bare in the air after the packing bags cannot exceed

72 hours.

B. The temperature of reserve for products which are not used out is 25

℃

±3

℃

, and

the humidity is >40% but <60%.

C. It is advised to use hand weld since lens are not endurable with high temperature.

3. Products should avoid machinery pressure and strong shake during cooling after tin is

welded.

4. Fast cooling is not allowed.

5. Weld on anamorphic pcb is not allowed.

6. Don’t touch water, il and organic liquor.

7. Current should be considered when products which are used in max. temperature.

8. The appearance and size of products can be revised without any notice.

9. Requirements for electrostatic prevention:

Wear wrist strap or static-proof glove when use products, and all the equipment,

fixtures and worktable must put to earth.

10.

Must use driver with constant current.

Hot Searches