- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

3300 mm

-

Backgauge Travel (mm):

-

20 - 650 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

AMUDA

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6900 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220V/380V, 220V/380V/Customized

-

Dimension(L*W*H):

-

3840x1610x1620mm

-

Year:

-

2022

-

Marketing Type:

-

New Product 2022

-

Name:

-

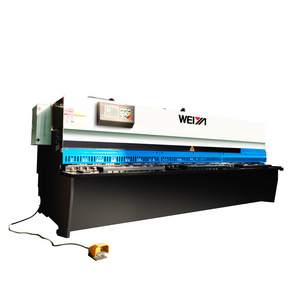

Hydraulic Swing Beam Shearing Machine

-

Control system:

-

MD11 Control System

-

Oil Volume:

-

290L

-

Color:

-

Customized

-

Application:

-

Industrial Metal Cutting

-

Cutting material::

-

Metal. alloy Metal aluminum

-

Distance between uprights::

-

3420mm

-

Strokes:

-

18 n/min

-

Working table height:

-

900mm

Quick Details

-

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

6 mm

-

Shearing Angle:

-

1.5°

-

Blade Length (mm):

-

3300 mm

-

Backgauge Travel (mm):

-

20 - 650 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

AMUDA

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6900 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220V/380V, 220V/380V/Customized

-

Dimension(L*W*H):

-

3840x1610x1620mm

-

Year:

-

2022

-

Marketing Type:

-

New Product 2022

-

Name:

-

Hydraulic Swing Beam Shearing Machine

-

Control system:

-

MD11 Control System

-

Oil Volume:

-

290L

-

Color:

-

Customized

-

Application:

-

Industrial Metal Cutting

-

Cutting material::

-

Metal. alloy Metal aluminum

-

Distance between uprights::

-

3420mm

-

Strokes:

-

18 n/min

-

Working table height:

-

900mm

Products Description

Main Features:

Special CNC system for plate shears.

Real time display of rear retaining position.

Multi step programming function, automatic operation, continuous positioning and automatic adjustment of rear retaining position.

Cutting counting function, real-time display counting,

Memory function when powered off: rear retaining position, program, parameter.

Ball screw linear guide ensures machining accuracy.

Machine display

The machine works continuously under the rated load, with no leakage and high precision.

The hydraulic system consists of electric motor, oil pump, valve block, straight line, pressure display, etc.

Sanyuan MD11:

LCD interactive interface display is more humanized.

•Debugging free function, only need to count twice.

•Frequency conversion positioning, PID algorithm, one step in place.

•9 products can be programmed, and 9 work steps can be entered for each product.

•One click restore factory settings, no longer afraid of beginners to adjust parameters.

•Sequential counting effect, counting is more humanized.

1,

Supporting Platform

(Ball type)reduces friction

2, Press cylinder, small

3,

Tube Joints

4.

Ball screw liner guide

5,

adjustment of blade gap

6,

Back gauge motor

7,

Hydraulic valve block with pressure display

8

,Main Motor,

fully enclosed, self-fan cooling, asynchronous motor.

9,

Electric Components

10,

Foot switch

International Brand Endorses

Main Configuration

|

NC Control system

|

ESTUN E21s/DELEM DAC360/MD11

|

|

Main Electric Components

|

Schneider Electrical from French

|

|

Main Motor

|

Siemens from Germany Brand

|

|

RAM Drive

|

Energy-saving servo drive from Taiwan delta

|

|

Hydraulic System

|

Bosch-Rexroth form Germany

|

|

Sealing Element

|

anti-corrosion

|

|

Tubing connector

|

EMB form Germany

|

|

Ball screw/ Polished rod

|

HIWIN from TaiWan

|

|

Foot Switch Electric Components

|

Schneider Electrical from French

|

|

Safety light certain

|

(Optional)

|

Our Work Shop

Safety & Reliability

All components are certified in accordance with European standards,mainly from Germany, USA, Holland, Italy and Switzerland. All structural parts are calculated by the finite element method and only high quality steel S275 and S355 JR namely J2 (+ N) is used.

Workbench protection

Laser protection: The blade stops when obstacle detected by laser.

Laser protection: The blade stops when obstacle detected by laser.

Mechanical back

Light curtain protection or Point protection or safety fence, to warn people the dangerous working areas.

Light curtain protection or Point protection or safety fence, to warn people the dangerous working areas.

Worktable sides

Safety Fence to prevent people from careless entry.

Safety Fence to prevent people from careless entry.

Hot Searches