- Product Details

- {{item.text}}

Quick Details

-

Model:

-

sisic ceramic

-

Hardness:

-

above 92HRA

-

Compressive strength:

-

above 2200MPa

-

Flexural strength:

-

above 400MPa

-

Silicon carbide content:

-

above 98%

-

Modulus of elasticity:

-

400 GPa

-

Thermal conductivity:

-

100-120 W/m.K

-

Supplier type:

-

Manufacturer

Quick Details

-

Place of Origin:

-

Henan, China

-

Name:

-

industrial ceramics

-

Volume density:

-

3.10-3.15

-

Model:

-

sisic ceramic

-

Hardness:

-

above 92HRA

-

Compressive strength:

-

above 2200MPa

-

Flexural strength:

-

above 400MPa

-

Silicon carbide content:

-

above 98%

-

Modulus of elasticity:

-

400 GPa

-

Thermal conductivity:

-

100-120 W/m.K

-

Supplier type:

-

Manufacturer

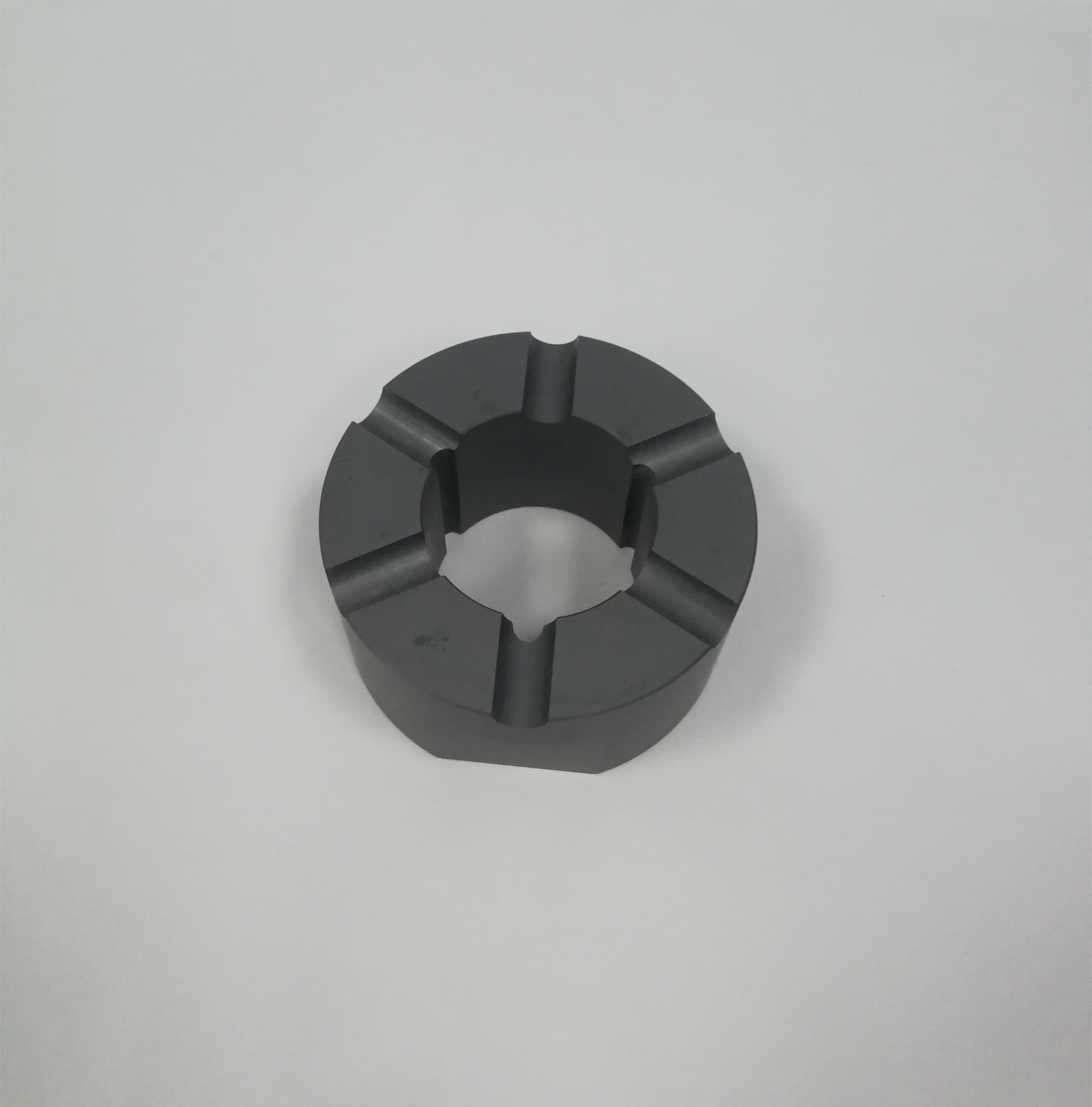

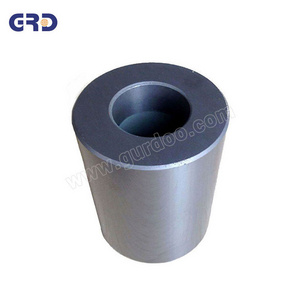

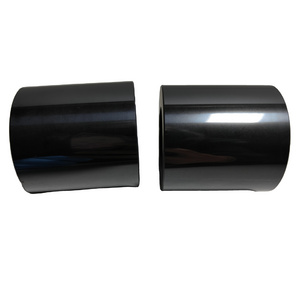

Silicon carbide sealing ring bushing for magnetic drive pumpve pump

Excellent low density ,high hardness and also provide customized production.

our products :

the parameter of our product .

| Parameter | SSiC | SISIC |

| Purity( % ) | >98 | >90 |

| Hardness( HRA ) | ≥92 | ≥90 |

| Grain Size( um ) | 0.5~0.7 | 8~20 |

| Density( g/cm3 ) | 3.10~3.15 | 3.03~3.08 |

| Bend Strength( MPa ) | 400-580 | 350-450 |

| Compressive Strength(MPa) | >2200 | >2000 |

| Fracture Toughness( MPA ) | 3.05-4.6 | 4.3 |

| Elastic Modulus( GPa ) | >400 | >360 |

| Thermal Conductivity(W/M.K) | 100~120 | 50~100 |

| Coefficient of heat Expansion( L/°C ) | 4.02x10-6 | 4.3x10-6 |

| Poisson Ratio | 0.14 |

0.15

|

Features of ssic ceramic :

1) Heat shock stablity

2) chemical corrosion-resistant( resistant to strong acid/strong alkali /salt / gas / deleterious )

3) High temper-endure(up to 1650°)

4) Wearing/corrosion/oxidation resistant

5) Highly performance of mechanical strength

6) Cleaning or etching the hardest sub-surfaces

7) long life high hardness resistant to wear; especially resistant to hydrofluoric acid

8) Used for grinding, lapping, and wire saw cutting as well as abrasive blasting

why chose us?

|

Our advantages

|

High quality |

|

Competitive price |

|

| Strict delivery time | |

| Good after-sales service | |

|

Professional producer for 10 years |

|

|

Gold supplier 3 th year |

|

|

Strict quality control |

4.Applications of sisic ceramic :

With silicon carbide ceramics the material properties remain constant up to temperatures above 1,400°C. The high Young’s modulus > 400 GPa ensures excellent dimensional stability. These material properties make silicon carbide predestined for use as a construction material. Silicon carbide masters corrosion, abrasion and erosion as skillfully as it stands up to frictional wear. Components are used in chemical plants, mills, expanders and extruders or as nozzles, for example.

“The variants SSiC (sintered silicon carbide) and SiSiC (silicon infiltrated silicon carbide) have established themselves. The latter is particularly suitable for the production of complex large-volume components.”

Silicon carbide is toxicologically safe and can be used in the food industry. Another typical application for

silicon carbide components

is dynamic sealing technology using friction bearings and mechanical seals, for instance in pumps and drive systems. Compared to metals, silicon carbide enables highly economical solutions with longer tool life when used with aggressive, high-temperature media. Silicon carbide ceramics are also ideal for use in demanding conditions in ballistics, chemical production, energy technology, paper manufacturing and as pipe system components.