- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Can be customized

-

Year:

-

2022

-

Power (kW):

-

252.8 kW

-

Weight (KG):

-

30000 KG

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUXI

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Can be customized

-

Year:

-

2022

-

Power (kW):

-

252.8 kW

-

Weight (KG):

-

30000 KG

-

Marketing Type:

-

Ordinary Product

Product Description

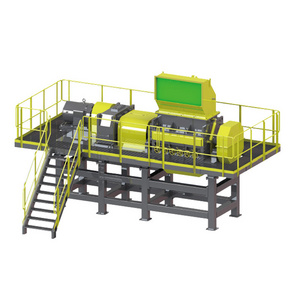

Tyre recycling machine

The waste tire powder recycling production equipment is a new environmentally-friendly and energy-saving 800 alloy roller mill developed by Yuxi Machinery.

The rubber roller mill is automatically ground into 15-80 mesh rubber powder. After the screening, the rubber powder can be sold in bags. The required number of meshes, one-stop production of complete equipment, combined with roller compaction, effectively control the pulverization temperature to ensure the quality of the pulverized material.

Products Parameter

|

No.

|

Name

|

Quantity

|

Motor

|

|

1

|

Tire Debeader

|

1 set

|

7.5kw

|

|

2

|

Tire Cutter

|

1 set

|

7.5kw

|

|

3

|

Tire Shredder

|

1 set

|

2*22+3 kW

|

|

4

|

Rubber Crushing Mill

|

1 set

|

132kw

|

|

5

|

conveyor Equipment

|

3 set

|

2.2kw

|

|

6

|

Magnet Separator

|

2 set

|

1.1KW+2.2KW

|

|

7

|

Shaking Screen

|

2 set

|

3kw

|

|

8

|

Fiber Separator

|

1 set

|

11kw

|

Application

Raw materials

:waste tire of bicycles, tractors and cars,sole,gasket, rubber factory scrap, conveyor belt, ect.

Application

Runways, school playgrounds, garden trails, bowling alleys, sidewalks, composite rubber floor tiles, anti-static floor tiles, artificial turf, playgrounds, artificial grass football fields, kindergarten sports venues and casino tennis and basketball courts. Rubber floor tiles, plastic track, lawn quartz sand, cottonseed granules, tennis courts, volleyball courts, golf courses, airplane courts, basketball courts and leisure casinos, EPDM safety mats, gym mats, all kinds of court mats.

The waste tire recycling output has wide usage and market. With our knowledge of the market, the following buyer channels could be considered:

Steel milling companies

Roofing and Construction companies

Chemical manufacturing companies

Tires manufacturing companies

Automobile manufacturing companies

Shoes and flip flops manufacturers

Asphalt producing companies

Working Principle&Processing

Cut off tyre steel bead----cut tyre body into strips ----cut the strips into 50*50mm-----crush into 5mm-----separate steel wire------separate fiber----pure rubber granules (5-6mm)

Tire Debeader

The tire debeader is composed of motor, hydraulic system, hook and frames. It’s used to draw out the wire rings from the tire rims, which will greatly protect the blade of the tire shredder.

Tire Cutter

The tire cutter can cut off all kinds of tires such as car tires, truck tires and passenger tires. It is composed of motor, hydraulic system, working oil cylinder, a pair of blades, frame and rotating mechanism

Tire Shredder

The double shaft shredder is specially designed for tire chips size separation. The shredded chips from prime shredder will drop on the rotary screen, and small chips will fall on the conveying belt, the big chips will be feed in the shredder for shredding and recycling again. The final chips will be around 50~60mm.

Rubber Mill Crusher

The double shaft shredder is specially designed for tire chips size separation. The shredded chips from prime shredder will drop on the rotary screen, and small chips will fall on the conveying belt, the big chips will be feed in the shredder for shredding and recycling again. The final chips will be around 50~60mm.

Magnet Separator

The rollers There is a magnet inside; the magnet of the magnetic separation device of the previous layer is provided with a separation plate obliquely below; and the impurity discharge plate extending to the rear of the magnetic separation device of the next layer is provided below the separation plate.

Successful Cases

2019 Jamaica 1t/h tyre recycling plant

2020 South Africa 800kg/h tyre recycling project

2021 Mexico 500kg/h tire recycling palnt

2021 India 1500kg/h tyre recycling project

Our Services

1.2-3 engineers will be sent to help you installing the machine, debugging the machine, training your worker, until your machines working normally and your workforce operate skillfully.

2.2 year warranty for the spare parts and 20 years warranty for the heavy duty machine(without spare part) in normal working process.

3.Spare parts delivered at cost in short time to ensure your daily production.

4.Life-long maintaining and technical support.

5.Before leaving the factory, we will assemble all the equipment into production lines, simulate the actual use conditions for testing, to ensure the production line capacity and product quality. We sincerely invite customers to visit the operation of the equipment and receive relevant operation and maintenance training

About Us

YUXI has the know-how, the experience and the capability to perform all aspects of a supply contract – from design to commissioning. Recycling plants and machinery manufactured and supplied by YUXI have converted millions of tons of industrial and consumer scrap into valuable commodities year after year, at the same time helping to protect the environment. So let YUXI assist you in achieving your goal.

Hot Searches