- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

UNIQUE

-

Dimension(L*W*H):

-

12x2.5x3.5m

-

Weight:

-

41 KG

-

Marketing Type:

-

Hot Product

Quick Details

-

Application:

-

quarry, mining, metallurgy

-

Capacity(t/h):

-

100

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UNIQUE

-

Dimension(L*W*H):

-

12x2.5x3.5m

-

Weight:

-

41 KG

-

Marketing Type:

-

Hot Product

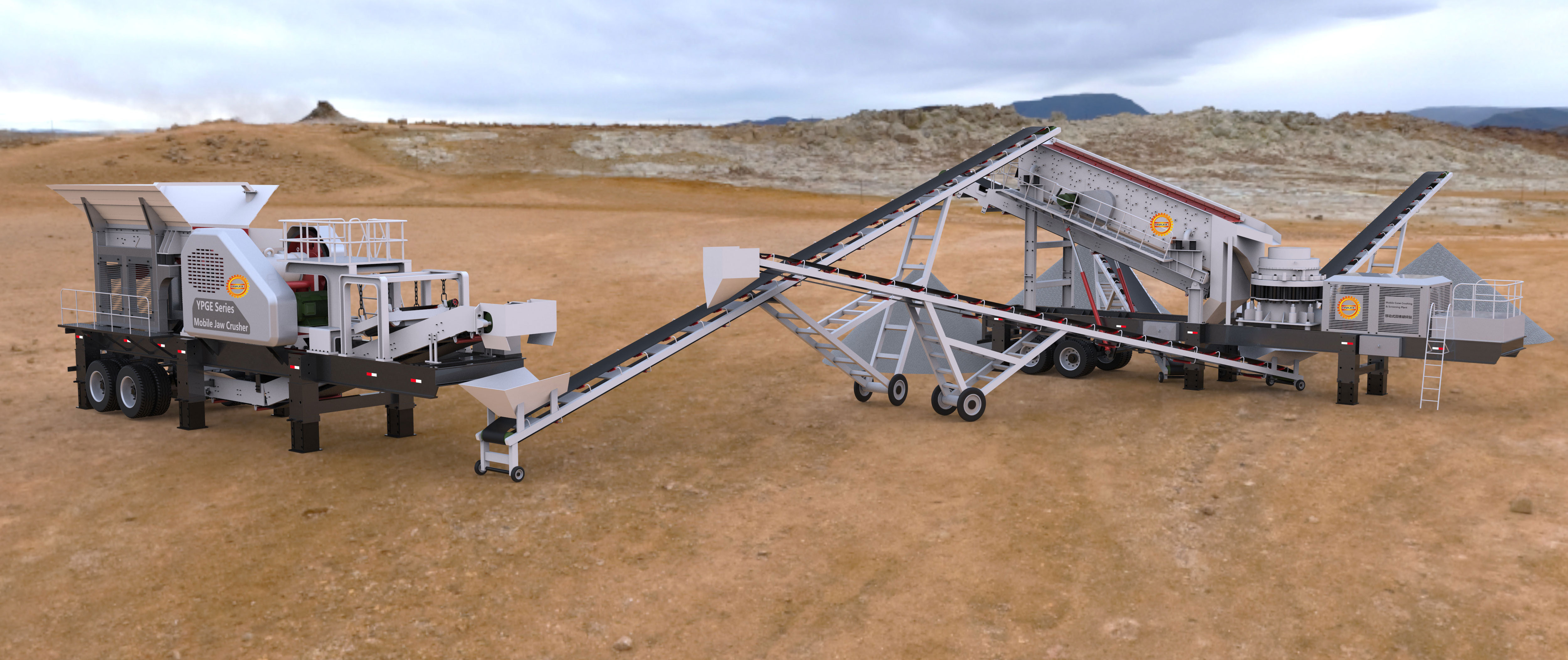

Mobile crusher plant/portable cruhsher plant/mobile crushing plant is mainly used in metallurgy, chemical industry, building materials, and utilities often need to be relocated material processing operations, especially for the job of highway, railway, hydropower project demaning liquidity stones. User can have a variety of configurations depending on the type, scale, and size of different raw materials.

The mobile crushing plant mainly includes: mobile impact crushing plant, mobile cone crushing plant,mobile jaw crushing plant, mobile VSI crushing plant and mobile screening plant. It also can be divided into track mounted crushing plant and wheel mounted crushing plant in terms of driving mode.

Advantages

1. Good Mobility

2. Integration of the entire units

3. Reduce material handling costs

4. Directly effective job role

5. Combination of flexibility, adaptability

6. Reliable, easy maintenance

Mobile crusher plant has good flexiblility and mobility, and can save a lot of infrastructure and relocation costs; can do crushing of material on site, and can be moved with the mining of raw materials face forward, thereby significantly reducing the cost of transporting materials.

Main Specification of Mobile Jaw Crushing Plant

|

Model Parameters |

YDS50 |

YDS80 |

YDS100 |

YDS180 |

|

Vibrating feeder Model |

GZT-0724 |

GZT-0932 |

GZT-0940 |

GZT-1148 |

|

Jaw crusher Model |

PE-400x600 |

PE-500×750 |

PE-600×900 |

PE-750×1060 |

|

Main Belt conveyor |

B650=6m |

B800=7m |

B1000=8m |

B1000=11m |

|

Adjustable Range of Discharge Opining(mm) |

40-100 |

50-100 |

95-165 |

80-180 |

|

Capacity(t/h) |

10-35 |

25-60 |

30-85 |

72-150 |

|

Power(kw) |

43 |

57 |

72 |

147 |

|

Transportation Dimension( LxWxH) |

8600x2520x3770 |

9600x2520x3500 |

11097x3759x3500 |

1330x2900x4440 |

|

Separators |

RCYD |

RCYD |

RCYD |

RCYD |

|

Mobile Frame |

biax |

biax |

biax |

triaxial |

Main Specification of Mobile Cone Crushing Plant

|

Model Parameters |

YDS50 |

YDS80 |

YDS100 |

YDS180 |

|

|

Transportation Dimension

|

L*W*H(mm) |

11300*2780*4250 |

15000*2865*4300 |

10000*2780*4160 |

15500*2865*4300 |

| Weight(kg) |

29000 |

42900 |

22400 |

55600 |

|

| Axle Load(kg) |

19000 |

29000 |

14300 |

35600 |

|

|

Cone crusher |

Model |

PYB900 |

PSGB091 |

PYB1200 |

PSGB1321 |

|

Max Feeding Size(mm) |

50-160 |

860-180 |

60-180 |

80-240 |

|

|

Adjustable Range of Discharge Opining(mm) |

9-32 |

9-32 |

9-32 |

9-51 |

|

| Vibrating Screen |

Model |

3YA1235 |

3YA1548 |

3YA1848 |

3YA2154 |

|

Belt Conveyor

|

Model |

B800*7.2m |

B1000*8.2m |

B1000*7.2m |

B1000*8.2m |

| Capacity(t/h) |

40-170 |

60-235 |

60-235 |

70-390 |

|

| Trailer |

biax |

biax |

biax |

triaxial |

|

Main Specification of Mobile Impact Crushing Plant

Main Specification of Mobile Impact Crushing Plant

|

Model Parameters |

YDS50 |

YDS80 |

YDS100 |

YDS180 |

|

Vibrating Screen |

3YA1235 | 3YA1545 | 3YA1548 | 3YA1848 |

|

Impact Crusher Model |

PF-1007 | PF-1010 |

PF-1214 |

PF-1315 |

|

Discharge Conveyor |

B650*7m |

B800*7m |

B1000*10m |

B1000*11m |

|

Belt Conveyor |

B650*9m |

B800*10m |

B1000*10m |

B1000*9m |

|

Belt Conveyor |

B650*5m |

B800*6m |

B1000*6m |

B1000*7m |

|

Transportation Dimension L*W*H(mm) |

10800*2480*4170 | 12200*2743*4200 | 12500*2900*4200 | 13000*3100*4300 |

| Trailer |

biax |

biax |

biax |

triaxial |

Mobile crushing and screening equipment includes primary crushing plant and secondary crushing and screening plant and belt conveyors, each plant at all levels is an independent working unit and can finish its different responsibilities of its commitment, the belt conveyor is responsible material transmitting and piling up between each crushing plants.

Structural Features

High performance crusher

Vehicular motors and electrical control cabinet integration

Feeder and vibrating screen integrated with jaw crusher, cone crusher, vertical impact crusher

Vehicular integrated installation of Under-Sieve belt conveyors, vibrating screen, and crusher

Vehicular installation support, convenient and efficient equipment stationing

Steering traction axis, convenient for road transport and in-depth facility

Packaging:

standard ContainerMobile Crusher Plant for Sale Packs or in Bulk.The electrical motor or spare parts will be packed by wooden case or steel frame.Unique offers various ways of package, fumigation-free wooden cases, steel plate cases, or as the clients' request. Most of the time, the equipment will be loaded to the containers in the factory. Unique workers make sure all equipment are steady and fixed before close the door of the container, there will be no damage during transporation and shipment.

Shipping:

we deliver the cargo to China's main sea ports,such as Qingdao,Tianjin,Shanghai etc.And then the container will be transported to your country by sea.

After-sales service support

1.more than 12 months' warranty period

2.Erection and Commissioning

3.Operator Training

4.Spare Parts Supply

Normally,Equipment spares will be offered with manufacturing cost in at least 10 years since the order is placed. To establish long term cooperation, we will regularly call and email our clients, to check the equipment working condition, offer suggestions for maintenance, and if necessary we will pay a visit to clients to solve the problems caused during equipment working.