- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

According To The Capacity

-

Weight:

-

30000 KG

-

Key Selling Points:

-

Economic Quotation

-

Capacity:

-

10-10,000 T

-

Silo Life:

-

25-40 Years

-

Coating:

-

Galvanized 275-600g/m2

-

Monitoring System:

-

Temperature and Moisture Supervision SIMENS PLC, etc.

-

Auxillary System:

-

Drying, Cleaning, Dedusting, Lifting and Conveying, etc.

-

Handling equipment:

-

Bucket elevator, drag conveyor, belt conveyor, screw auger, etc.

-

Bottom Type:

-

Flat/Hopper bottom

-

WhatsApp:

-

+86 13598071775

-

Usage:

-

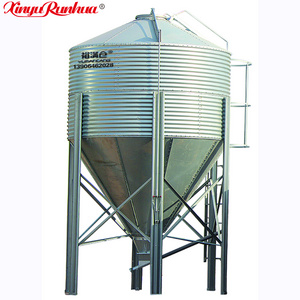

Silo for feed/grain cereal storage

Quick Details

-

Core Components:

-

Steel Plate

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HKB

-

Dimension(L*W*H):

-

According To The Capacity

-

Weight:

-

30000 KG

-

Key Selling Points:

-

Economic Quotation

-

Capacity:

-

10-10,000 T

-

Silo Life:

-

25-40 Years

-

Coating:

-

Galvanized 275-600g/m2

-

Monitoring System:

-

Temperature and Moisture Supervision SIMENS PLC, etc.

-

Auxillary System:

-

Drying, Cleaning, Dedusting, Lifting and Conveying, etc.

-

Handling equipment:

-

Bucket elevator, drag conveyor, belt conveyor, screw auger, etc.

-

Bottom Type:

-

Flat/Hopper bottom

-

WhatsApp:

-

+86 13598071775

-

Usage:

-

Silo for feed/grain cereal storage

| Reputable Steel Silo Manufacturer in China |

- Provide an integrated grain storage system, include grain receiving, cleaning, drying, safety storage, distribution, and electric control system.

- Provide EPC solution for bulk material storage used in commercial center, food processing, depot, port, etc. industry.

- Rich experience for an overseas project, one-stop service from design to site construction.

- Built projects in Thailand, Tanzania, Uganda, Philippines, Malaysia, Vietnam, Kenya, Nigeria, Ecuador, Cyprus, etc.

- Technology is the base of development, quality is the reason for existence, credit for friends overseas, present scientifically advanced silo projects for user profit.

HKB Grain Silo is widely used for grains storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseeds, peanuts, flour, and other powder materials, oat, special grain, and seeds, etc.

What you can get from HKB

--

Grain Storage Silo Turn-key Solution

:

- Engineering design: be scientific, be flexible, be economical, be practical.

- Solid silo and steel structure, high-quality handling equipment, high efficient drying system.

- Our professional package service including protective equipment package, transportation, customs clearance.

- Experience overseas site construction for project success landed, quality warranty till final acceptance test.

| The Build to Last Solid Silos |

|

Flat Bottom Grain Silo

Hopper Botom Grain Silo

|

How do we assure the silo solidity?

1- Roof Top: The roof is designed to stand up even the harshest environment of extreme snow disaster with the echo of top and down part strong structure and connecting radial ribs which is Z interconnected again itself. Roof panels incorporate with ribs with over and under lap profiles ensuring a precise fit.

2- Body Steel Plate: A commercial 275g/m2 double galvanized steel coating increases life and durability. 450g/m2 and 600g/m2 coating available for customized orders. Each sidewall sheet is manufactured from high-tensile steel that can overcome extreme power, pressure.

3- Stiffeners: HKB’s high tension stiffener(can be located inside or outside the silo,) profiles make bins stronger allowing silos to stand well even under an extreme hurricane. Base stiffener boots are coated so they won’t rust over time.

4- Wind Ring: For tall silos or that need to resist heavy wind. Wind ring and brackets reduce bolt holes in stiffeners; Swaged technology ensure silo power load capacity.

5- High strength bolts and screws: HKB’s high strength bolts paired with sealing washers, coated hardware provides added protection from rust to ensure your grain bin stands the test of time.

6- Manhole: Double layer security locking manhole system.

7- Wide Flange H Beam Support Structure: The wide flange H-Beam support structure has the strength and durability to support the heavy hopper silo loads for a long time, and with consideration of wind and seismic requirements. |

| HKB Solid Silo Costruction Details |

| HKB Most Popular Silo Models |

Scientifically speaking, the silo capacity should be measured with volume (m3). Even in the same silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a grain density of 0.75kg/m3, and surely HKB customizes silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model |

TCZK 03605 |

TCZK 04507 |

TCZK 05507 |

TCZK 06406 |

TCZK 07307 |

TCZK 07313 |

TCZK 11010 |

TCZK 12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

|

Volume(m³) Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model |

TCK 10014 |

TCK 11915 |

TCK 13715 |

TCK 15514 |

TCK 15518 |

TCK 18321 |

TCK 24718 |

TCK 25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

|

Volume(m³) Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |

| Optional Accessories |

Starting from the initial project analysis, to develop your custom grain silo system plan and to the final turnkey completion of the project, HKB’s engineers will stand together with you to get the best matching profitable solution.

Henan Haokebang Machinery Equipment Co., Ltd. specializes in the production of 100-10,000 ton hopper bottom and flat bottom corrugated galvanized steel silos. According to various factors such as site, weather, and geology, we provide professional silo design, equipped with elevators, unloading pits, pre-cleaner, conveyors, sweeping auger and other accessories to meet the diverse needs of customers.

| Advanced Production Equipment |

Standing on our strong integral solution design power, HKB’s s rich manufacturing expertise guarantees the best workmanship of the whole silo system. The bolt steel plate production line is imported assuring bolt plates high precision and max sealing bolt connection. The introduction of advanced laser cutting machine, intelligent CNC robot and silo hoarding forming machine ensures that the steel plate is cut accurately and efficiently , the incisions are flat and beautiful , the silo has high strength , good seismic performance and long service life .

| Packaging & Shipping |

| Experienced Installation Team |

HKB’s own installation engineers team plays a respectable role in the success high-performance whole silo system. Our motivated team has rich installation experience for various types of silos, work under strict and standardized installation management system, thorough installation cross-checking rules, and they promise one-time project acceptance.

| Worry-free After-sale Service |

- HKB provides advanced grain safety storage technology to assure your grain 100% quality stability.

- Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- Routinely telephone track to remove all might be problems or issues guarantying the whole system long-lasting safety and reliability.

- HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the silo system well.

| Part of HKB Silo Cases |

| China's Powerful Factory Trustworthy |

Henan Haokebang Machinery Equipment Co., Ltd. is located in Henan Province, China, covering an area of 32,000 square meters and having a standardized heavy-duty industrial plant of 15,000 square meters. The company specializes in the production of grain dryers, silos, tubular dryers, mesh belt dryers, grain cleaning screens and other grain processing equipment.

The company is well-equipped with more than 20 large and medium-sized machining, riveting, and assembly equipment, including fully automatic bending machines, laser cutting machines and other modern production equipment. Our company has more than 100 management personnel and engineering and technical personnel with intermediate and senior professional titles. It is a modern enterprise integrating R&D, production, sales and maintenance. Products have passed ISO, CE and other certifications, attracting customers from all over the world with efficient sales team and competitive price advantage, we have exported to more than 50 countries, including the United States, Russia, South Korea, Nigeria, Tanzania, Uganda , Colombia, Thailand, Philippines, Zimbabwe, Kenya and other countries and regions.

The company has a large number of skilled technicians, professional overseas installation teams and experienced after-sales service teams, which can provide users with solutions and equipment from a single equipment to a complete set of grain cleaning, drying, storage, and selected systems. And professional customized service technical support, reliable spare parts supply and high-quality after-sales service.

Our service purpose: "Serve users, be responsible for users, and satisfy users!". Looking forward to get more cooperation.