- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

Product Name:

-

Die Cutting Punch Pins High Speed Steel Punch Die Pin Punch

-

Application:

-

Hardware Mould Industry

-

Surface treatment:

-

Chrome plated,Titanium plating,Polished

-

Size:

-

Customized Size

-

Material:

-

SKD11/DC53/SKH-9/SKH-51/W6/ASP23/CD650/YG8/V3 ect

-

Design software:

-

CAD

-

MOQ:

-

1 Piece

-

Delivery:

-

5-12 Days

Quick Details

-

Shaping Mode:

-

Plastic Extrusion Mould

-

Place of Origin:

-

Guangdong, China, GuangDong, China

-

Brand Name:

-

HTX(HengTongXing), HTX

-

Model Number:

-

Customized

-

Product Name:

-

Die Cutting Punch Pins High Speed Steel Punch Die Pin Punch

-

Application:

-

Hardware Mould Industry

-

Surface treatment:

-

Chrome plated,Titanium plating,Polished

-

Size:

-

Customized Size

-

Material:

-

SKD11/DC53/SKH-9/SKH-51/W6/ASP23/CD650/YG8/V3 ect

-

Design software:

-

CAD

-

MOQ:

-

1 Piece

-

Delivery:

-

5-12 Days

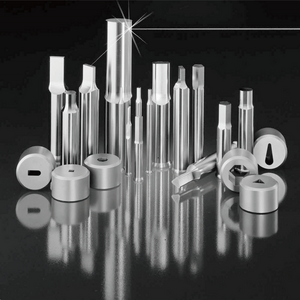

Product Display

HASCO DME MISUMI Mould Parts Hole Punching Die Punch Machine Carbide Steel Punch Pin

Prove us with quality and create trust with heart

|

Manufacturer

|

Shenzhen Hengtongxing Technology Co., Ltd.

|

|

Product Name

|

punch pin

|

|

Materials

|

45#、S50C、CR12/CR12MOV、SKD11、DC53、SKH-9、SKH-51、SKH-55、ASP23、ASP30、ASP60、CD650、2210、YG15、YG8、V30、KD20 etc

|

|

Standard

|

Standard Hardware/ Plastic Parts as per MISUMI, DME, HASCO, FIBRO, CUMSA, STRACK, DAYTON NON-Standard parts can be designed or

made customized |

|

Hardness

|

HRC58-60、HRC64-66、HRC88-90

|

|

Tolerance

|

±0.001mm

|

|

Surface treatment method

|

Black-plated titanium, yellow-plated titanium, chrome-plated, nickel-plated

|

|

Heat treatment method

|

High frequency quenching, vacuum heat treatment, quenching and tempering treatment

|

|

production address

|

ShenZhen,GuangDong,China

|

|

Lead Time

|

Sampling: 3-5 workdays

Normal making: 5-10 workdays Complex design/making: 10-18 workdays |

|

Order Process

|

Customer inquiries → Provide Spec./CAD/3D drawing → Engineer check and quote → Offer PI → Customer Send PO → 50% advanced

payment(100% for First time cooperation) → Factory production process → QC passed → Packing and deliver at the first time → Fly to customers' hands soon! |

|

After-sales service

|

If you have any questions about the punch pin samples or products, please contact us, our team will solve the problem for you.

|

Our main products include precision punch pin, guide pillar, guide bush, guide pillar sets, dowel pin, support pin,ejector pin and sleeve, mold spring, ball cage, block sets of standard and non standard hardware, plastic and silicone mold components. The tolerance of machining accuracy can be within 0.005mm, coaxiality within 0.002mm, circularity within 0.003mm, surface roughness within Ra0.04, and diameter from 1mm to 600mm can be manufactured.

Application Field

Applications Field:

Application fields: Most of our products are used for mold accessories, but they can also be used in automobile industry,electronic communication industry, hardware industry, plastic industry, mechanical equipment, die casting and other major industries. Only drawings can be customized according to your needs

Why Choose Us

Hot Searches