- Product Details

- {{item.text}}

Quick Details

-

Spangle Type:

-

Regular Spangle

-

Hardness:

-

Full Hard

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

wanjintong

-

Length:

-

one coil

-

Grade:

-

dx51d

-

Product Name:

-

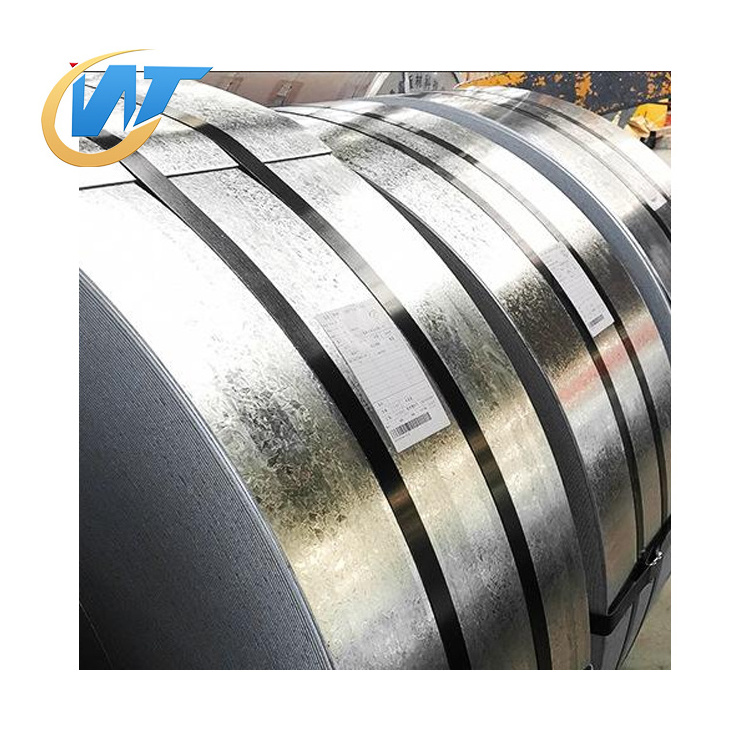

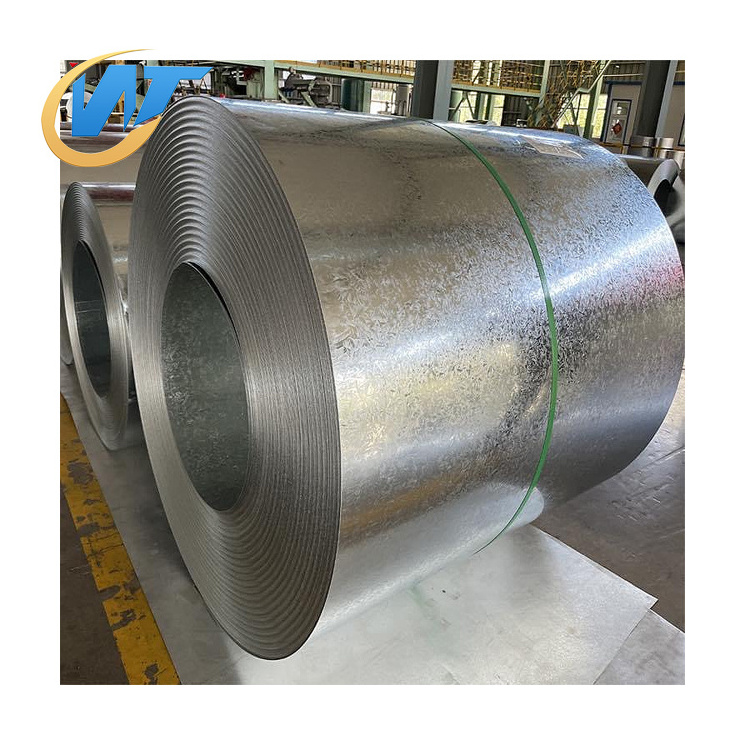

26 gauge Gi Galvanized Steel Sheet In Coils

-

Surface:

-

Galvanized Steel Strip

-

Keyword:

-

Prepainted Zinc Steel Coil

-

Shape:

-

Coil Roll

-

Surface Treatment:

-

Coated Galvanized

-

Material:

-

SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+Z Q195-q345

-

Special Use:

-

High-strength Steel Coil

-

MOQ:

-

1 Ton

Quick Details

-

Type:

-

Steel Coil

-

Thickness:

-

0.12-0.2

-

Coating:

-

Z181-Z275

-

Spangle Type:

-

Regular Spangle

-

Hardness:

-

Full Hard

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

wanjintong

-

Length:

-

one coil

-

Grade:

-

dx51d

-

Product Name:

-

26 gauge Gi Galvanized Steel Sheet In Coils

-

Surface:

-

Galvanized Steel Strip

-

Keyword:

-

Prepainted Zinc Steel Coil

-

Shape:

-

Coil Roll

-

Surface Treatment:

-

Coated Galvanized

-

Material:

-

SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+Z Q195-q345

-

Special Use:

-

High-strength Steel Coil

-

MOQ:

-

1 Ton

Product Description

Product Introduction

Galvanized coil, a thin steel plate that is immersed in a molten zinc bath to adhere a layer of zinc on its surface. The main production method is continuous galvanizing, which involves continuously immersing rolled steel plates in a molten zinc plating bath to produce galvanized steel plates; Alloyed galvanized steel plate. This type of steel plate is also manufactured using the hot dip method, but immediately after being removed from the groove, it is heated to around 500 ℃ to form an alloy coating of zinc and iron. This type of galvanized coil has good coating adhesion and weldability.

Surface Treatment

①

Passivation

The passivation treatment of the galvanized layer can reduce the formation of rust (white rust) under damp temperature storage and transportation conditions. But the anti-corrosion performance of this chemical treatment is limited and hinders the adhesion of most coatings. This treatment is generally not used on zinc iron alloy coatings. In addition to surface finishing, as a routine, the production plant passivates other types of galvanized coatings.

② oiling

Applying oil can reduce the corrosion of steel plates under humid storage and transportation conditions, and applying oil to passivated steel plates and strips will further reduce the corrosion under humid storage conditions. The oil layer should be able to be removed with a degreaser that does not damage the zinc layer.

③ paint seal

By applying an extremely thin layer of transparent organic coating film, an additional anti-corrosion effect, especially fingerprint resistance, can be provided. It can improve lubricity during molding and serve as an adhesive substrate for subsequent coatings.

4 Phosphating

Through phosphating treatment, galvanized steel plates with various coating types can be coated without further treatment, except for normal cleaning. This treatment can improve the adhesion and anti-corrosion properties of the coating, reducing the risk of corrosion during storage and transportation. After phosphating, it can be combined with suitable lubricants to improve molding performance.

Introduction to Zinc Layer

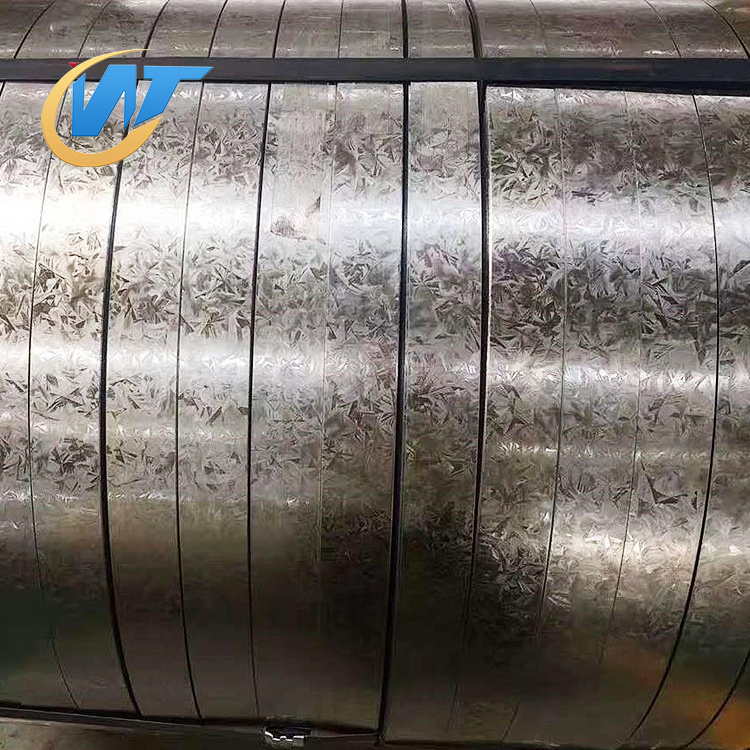

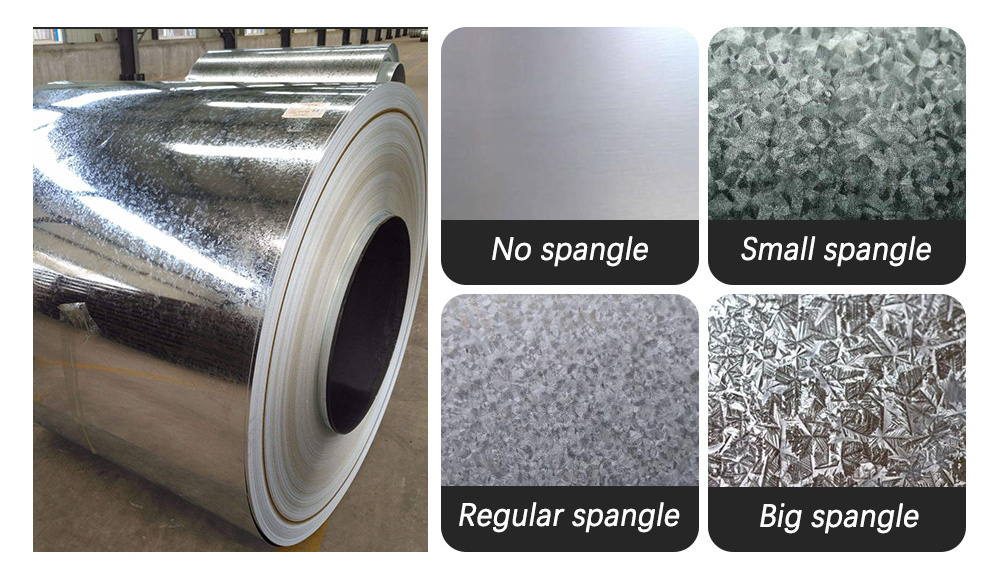

(1) Spangle coating

During the normal solidification process of the zinc layer, the zinc grains grow freely and form a coating with a clear morphology of zinc flakes.

(2) Minimized spangle coating

During the solidification process of the zinc layer, the zinc grains are artificially restricted, forming the smallest possible zinc flake coating.

(3) Spangle free

The coating obtained by adjusting the chemical composition of the plating solution does not have a visually visible morphology of zinc flakes and has a uniform and consistent

surface.

(4) Zinc-iron alloy coating

Heat treatment is carried out on the steel strip after passing through the galvanizing bath solution to generate an alloy layer of zinc and iron for the entire coating. This coating has a dark gray appearance, no metallic luster, and is easy to powder during intense forming. It is suitable for coatings that can be directly painted without further treatment, except for

general cleaning.

(5) Differential coating

For both sides of galvanized steel plates, coatings with different zinc layer weights are required.

(6) Skin pass

Finishing is a small deformation cold rolling process performed on galvanized steel plates for one or more of the following purposes.Improve the surface appearance of galvanized steel plates or be suitable for decorative coatings; Temporarily minimize the occurrence of slip lines (Luedes lines) or creases during processing in the finished product.

|

Technical Standard

|

EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653

|

|

Steel Grade

|

Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,

SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or Customer’s Requirement |

|

Type

|

Coil/Sheet/Plate/Strip

|

|

Thickness

|

0.12-6.00mm,or customer's requirement

|

|

Width

|

600mm-1500mm, according to customer's requirement

|

|

Type of Coating

|

Hot Dipped Galvanized Steel(HDGI)

|

|

Zinc Coating

|

30-275g/m2

|

|

Surface Treatment

|

Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U)

|

|

Surface Structure

|

Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS)

|

|

Quality

|

Approved by SGS,ISO

|

|

ID

|

508mm/610mm

|

|

Coil Weight

|

3-20 metric ton per coil

|

|

Package

|

Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by

seven steel belt.or according to customer's requirement |

|

Export market

|

Europe, Africa, Central Asia, Southeast Asia, Middle East, South America, North America, etc

|

Product advantages

Sufficient thickness of zinc layer

The quality of the zinc layer on the galvanized coil produced by our factory can reach 275g per square meter, and the thickness of the zinc layer can be customized according to customer needs. Our factory has strict quality inspection procedures to ensure that the quality of galvanized coils produced meets high standards.

Short production cycle and fast delivery

Our factory has multiple production lines that produce at the same time, with a daily output of up to several hundred tons, reducing losses in production, shortening production cycles, and meeting customer production needs. The produced galvanized coils will be quickly packaged and arranged for shipment, striving for the earliest possible delivery to customers.

Standard export packaging, no scratches

Our factory generally adopts standard export packaging or customized packaging according to customer needs. Be careful during the shipping process to ensure that the product does not show scratches. Fast delivery speed.

Company Introduction

Liaocheng Wanjintong Metal Materials Co., Ltd

Liaocheng Wanjintong Metal Material Co., Ltd. is the professional manufacturer of

Galvanized Coil in China

since 2015.

The factory covers an area of over 20000 square meters and has over 300 workers. We can provide cutting, slitting, film covering, and other non-standard processing services.

Also as a factory, Liaocheng Wanjintong has always been committed to offering clients at home and abroad the products of high quality involved in metal materials, metal products and the top-ranking service in accordance with the management concept of “quality, professionalism and sincerity”. The company is a manufacturer foreign trade cooperation. Building up wide international marketing network abroad, the products are mainly exported to Southeast Asia, Africa, Europe, North America and countries in the Middle East. By virtue of wide commodity information network, the company has partners around the world and has long-term and stable business with many overseas clients.

Certifications

Quality report of galvanized coil

Customer Reviews

Product packaging

FAQ

Q:Can you send samples?

A:Of course, we can send samples to all parts of the world, our samples are free, but customers need to bear the courier costs.

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:What are the shipping ports?

A:Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can choose other ports according to your needs.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-20 days, and may be delayed if the demand is extremely large or special circumstances occur.

Q:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion during ocean transportation, or customize according to customer needs.

A:Of course, we can send samples to all parts of the world, our samples are free, but customers need to bear the courier costs.

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:What are the shipping ports?

A:Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can choose other ports according to your needs.

Q:About product prices?

A:Prices vary from period to period due to cyclical changes in the price of raw materials.

Q:How long does your delivery time take?

A:In general, our delivery time is within 7-20 days, and may be delayed if the demand is extremely large or special circumstances occur.

Q:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion during ocean transportation, or customize according to customer needs.

Hot Searches