- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

600L

-

Weight (KG):

-

2000 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SUN

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

made to different models

-

Power (kW):

-

7.5 kW

-

Marketing Type:

-

New Product 2022

-

Heating method:

-

Steam

-

Volume:

-

1000L

-

Sealing Type:

-

Mechanial Seal

-

Function:

-

Mixing

-

Usage Range:

-

Powder/Slurry

-

Agitator:

-

Ribbon/screw/spiral belt

-

After Warranty Service:

-

Spare parts

-

After-sales Service Provided:

-

Online support

-

Certification:

-

ASME Certificate, CE Certificate

Quick Details

-

Barrel Volume (L):

-

1000L

-

Max. Loading Volume (L):

-

600 L

-

Range of Spindle Speed(r.p.m):

-

25 - 51 r.p.m

-

Max. Loading Capacity:

-

600L

-

Weight (KG):

-

2000 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SUN

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

made to different models

-

Power (kW):

-

7.5 kW

-

Marketing Type:

-

New Product 2022

-

Heating method:

-

Steam

-

Volume:

-

1000L

-

Sealing Type:

-

Mechanial Seal

-

Function:

-

Mixing

-

Usage Range:

-

Powder/Slurry

-

Agitator:

-

Ribbon/screw/spiral belt

-

After Warranty Service:

-

Spare parts

-

After-sales Service Provided:

-

Online support

-

Certification:

-

ASME Certificate, CE Certificate

Product Description

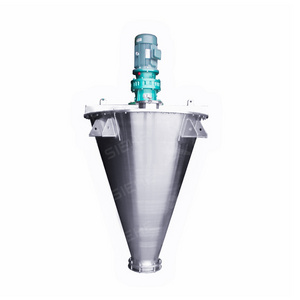

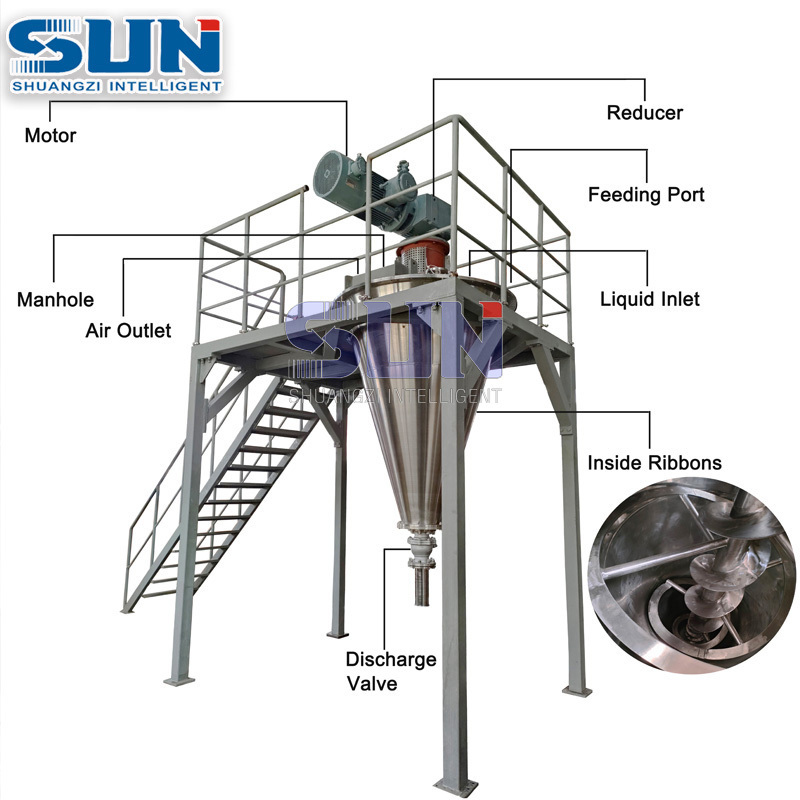

Vercial Conical Ribbon Mixer/Spiral Belt Blender With Low Price

is widely used in chemical,

traditional Chinese herb

, pesticide, fertilizer, dye, metallurgy, mining, food, dairy, monosodium glutamate, salt, rubber, plastic, building materials, paint, brewing, national defense, scientific research and other industries solid-solid (i.e. powder and powder) mixing; solid-liquid (i.e. adding liquid to powder) mixing; particle-grain (i.e. particle and particle) mixing; liquid-liquid (i.e. liquid and liquid) mixing . The machine has wide adaptability to the mixture, no dead angle, no deposition, no overheating for heat-sensitive materials; no pressure feeding and grinding for granular materials; no stratification for mixing materials with different specific gravity and different particle sizes. , Segregation phenomenon; it also has good adaptability to the mixing of various granular, fibrous or flake materials such as coarse, fine and ultrafine powder. It has the advantages of high mixing precision, large loading coefficient, fast speed, low energy consumption, safety, dust-free, good sealing performance, convenient operation, installation and maintenance.

Main Features:

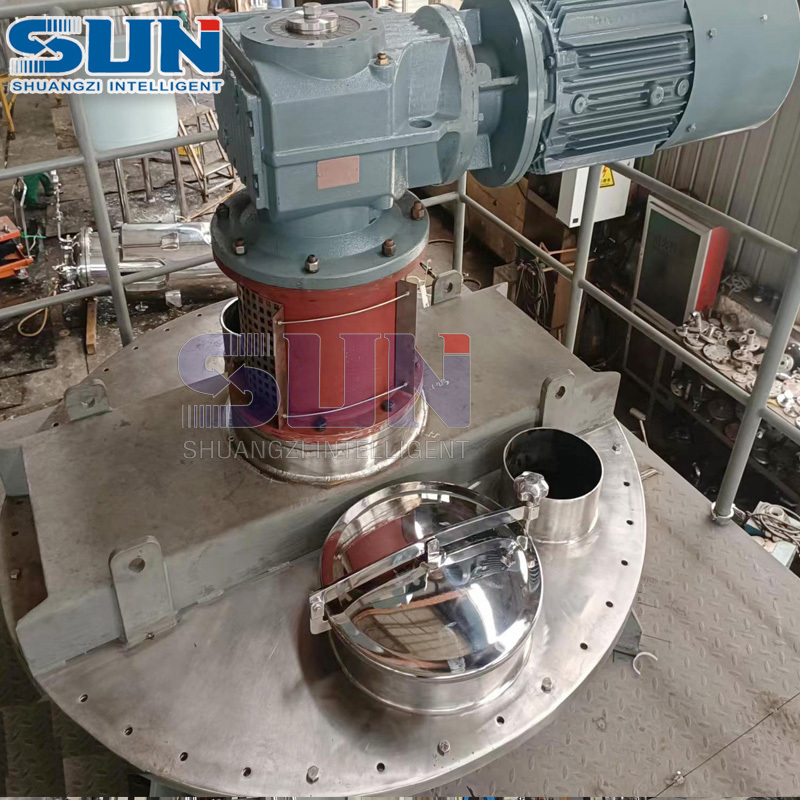

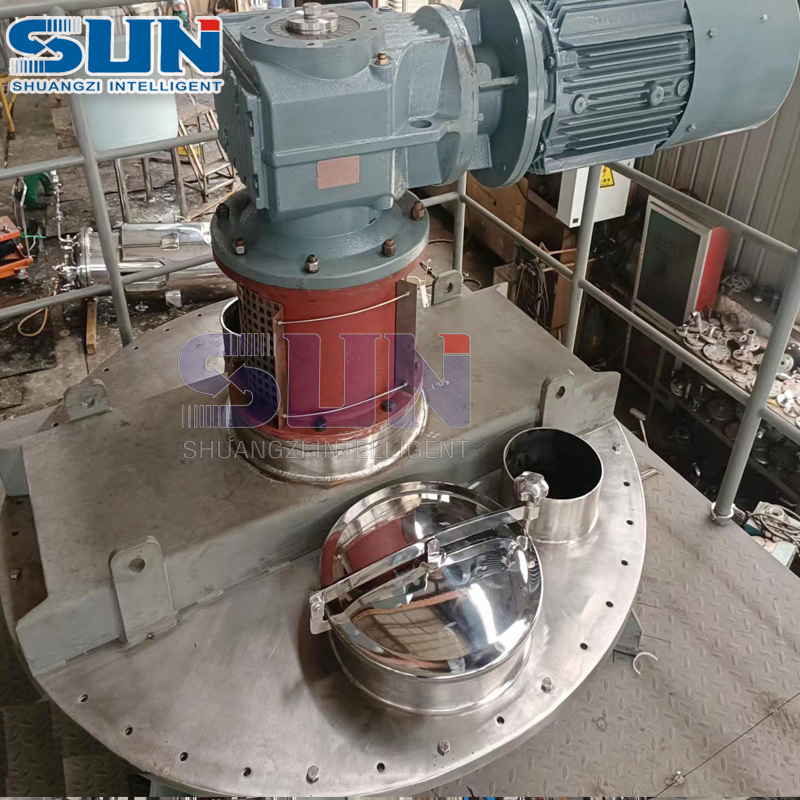

1. Transmission part: The machine adopts a cantilever shaft structure, the bearing end does not contact the material, the main shaft passes through the shaft hole of the reducer, and the shaft is fixed by a round nut, and the motor is started to drive the rotation of the main shaft.

2. Spiral part: There are inner and outer spiral belts in the cylinder, which can turn the material in a large range, so that the material can be quickly and uniformly mixed.

3. Cylinder body part: The cylinder body is a conical structure, which is used for loading materials. Make the material discharge quickly, cleanly, without material accumulation, and without dead angle of material discharge.

4. Cylinder cover part: The cylinder cover supports the entire transmission part, and the transmission part is fixed on the cylinder cover with bolts. There are several holes on the cylinder cover for feeding, observation, cleaning and maintenance.

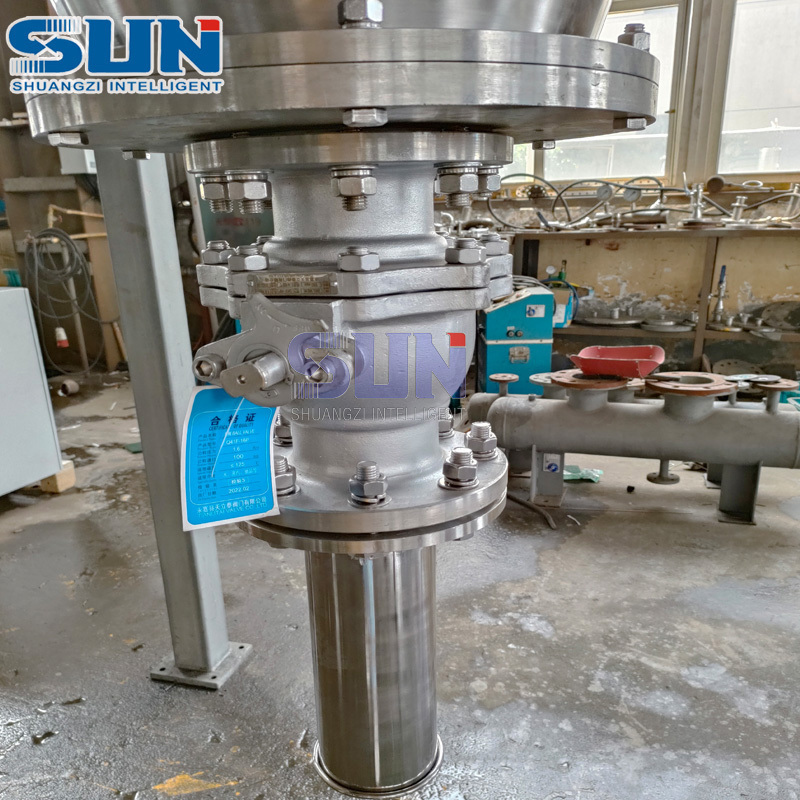

5. Discharge valve: The discharge valve is installed at the bottom of the cylinder to control the outflow and discharge of materials. The discharge valve can be divided into manual structure.

Parameters:

|

Model

|

Length(mm)

|

Width(mm)

|

Height(mm)

|

Power(kw)

|

Capacity(kg)

|

Weight(kg)

|

|

SLF-4

|

1850

|

2550

|

5900

|

7.5

|

700-1000

|

7500

|

|

SLF-6

|

2000

|

3200

|

6400

|

11

|

1000-1500

|

9500

|

|

SLF-7.2

|

3500

|

3300

|

7500

|

15

|

1200-1800

|

11500

|

Detailed Images

Certifications

Factory Equipment & Workshop

Sample Projects

Our service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.* Visit customers abroad

* Sample testing support.

* View our Factory.* Visit customers abroad

After-Sales Service

* 6 engineers and 15 workers has USA visa, no problem to go to USA, Canada and any other countries to do technical support

*Technical trainning, Technical documents,

*Customers field installation, field debugging

*One year quality guarantee

*Technical trainning, Technical documents,

*Customers field installation, field debugging

*One year quality guarantee

Package & Delivery

Big Tank Package

The big tank (reactor) will be wrapped by thick cloth and fitted in container directly.

Big Equipment Package

The big equipment will be wrapped by thick cloth and fitted in container directly.

Small Equipment Package

The small equipment will be packed in standard plywood cases

Related Products

Hot Searches