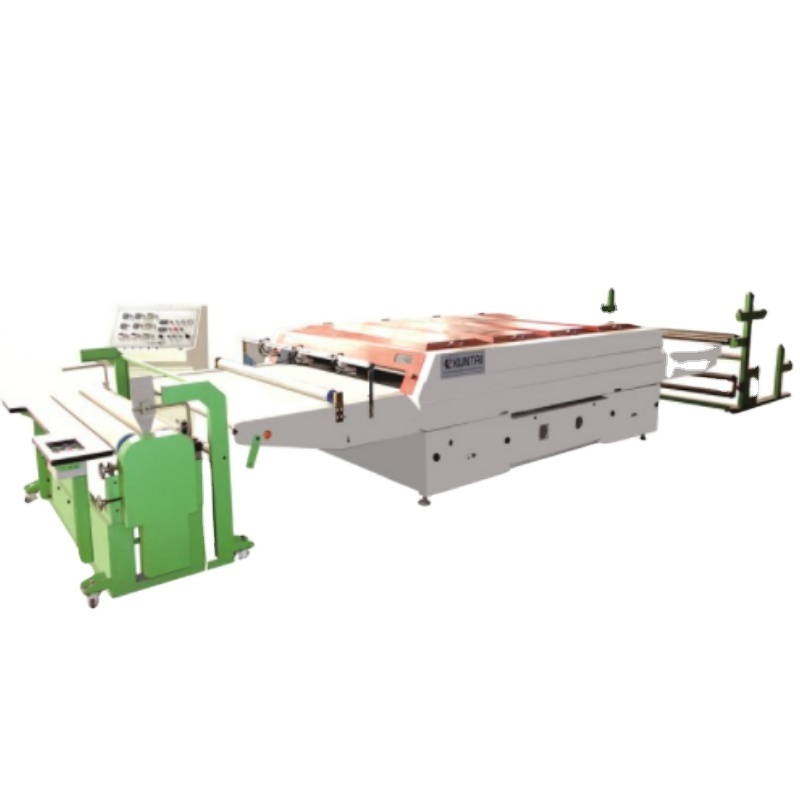

Application: the product is mainly used in garment fabrics, automobile interior decoration and other composite industries: This product can composite various thin and thick materials, such as spring Oxford cloth, Nisi spinning, fleece, knitted cloth, corduroy, TPU, PTFE. PE film and elastic cloth, Lycra, mesh cloth, all cotton sweat cloth, knitted cloth, non-woven cloth, towel cloth and so on.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZY

-

Power:

-

45KW

-

Dimension(L*W*H):

-

12.1m*3.8m*3.8m

-

Weight:

-

100

-

roller width:

-

2200mm

-

material width:

-

2000mm

-

machine speed:

-

20m/min-45m/min

-

Glue type:

-

Hot Melt PUR Glue

-

power:

-

45KW

-

Hot Melt Melter Capacity:

-

55Galon

-

Main Motor Brand:

-

Siemens

-

After-sales Service Provided:

-

Online Support

-

Function:

-

Automatic

-

Application:

-

Weaving

Quick Details

-

Voltage:

-

380V

-

Marketing Type:

-

Hot Sell

-

Production Capacity:

-

99%

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZY

-

Power:

-

45KW

-

Dimension(L*W*H):

-

12.1m*3.8m*3.8m

-

Weight:

-

100

-

roller width:

-

2200mm

-

material width:

-

2000mm

-

machine speed:

-

20m/min-45m/min

-

Glue type:

-

Hot Melt PUR Glue

-

power:

-

45KW

-

Hot Melt Melter Capacity:

-

55Galon

-

Main Motor Brand:

-

Siemens

-

After-sales Service Provided:

-

Online Support

-

Function:

-

Automatic

-

Application:

-

Weaving

Products Description

Brief Introduction

Machine Specification & Advantages

|

Machine Roller Width

|

|

2200mm

|

|

||

|

Maximum Material Width

|

|

2000mm

|

|

||

|

Machine Speed

|

|

20m/min-45m/min

|

|

||

|

Glue Type

|

|

Hot Melt PUR Glue

|

|

||

|

Heating Power

|

|

45kw

|

|

||

|

Drive Power

|

|

12kw

|

|

||

|

Hot Melt Melter Capacity

|

|

55Galon

|

|

||

|

Estimated Machine Dimension

|

|

12.1m x 3.8m x 3.8m

|

|

||

|

PLC Brand

|

|

Mitsubishi

|

|

||

Advantage 1

Pur hot melt adhesive compounding machine structure: the equipment control of PUR hot melt adhesive compounding machine adopts programmable PLC design and man-machine interface control, with humanized operation and simple maintenance. The tension-free feeding device is equipped with heating circulation system to facilitate the control of glue temperature rise and fall and stability. The bonding materials and finished products can adopt central coiling or surface selection as required, Gluing methods are divided into two options: dispensing and anilox coating

Advantage 2

1. The pur hot melt adhesive used does not contain solvent and is an ideal green environmental protection glue:

2. The product has no residual solvent, low production pollution emission, energy saving and small floor area;

3. The wet solid reaction of the composite process is irreversible, the bonding is firm, and the water washing fastness is good:

Advantage 3

4. Pur hot melt adhesive does not contain water and solvent, does not need to be dried, and has fast compounding speed: 5 strong viscosity, low glue consumption and cost saving;

6. Full linkage control of the composite process, no stretching of the substrate, light and soft, good hand feel;

7. The heat source is oil heat, fast heating and uniform heat;

8. The glue melting system is independent, and the glue melting is full and fast;

9. Dot pattern gluing, good air permeability and strong three-dimensional sense of the finished product; 10. Machine humanized design, saving operators;

11. With small quantity and diversified production design, cost saving and digital control system, the operability is better

Machine Application

FAQ:

Q Products price and discount:

A Wesupport customization.Pls feel free to tell us machiner details you wanted. You will get our reply in 24 hours

Q Delivery time

A Normally 30 days after deposit.lf the machine you need is in stock,we can ship it shortly.

Q Machine warranty

A One year.For any spare part,the customer can purchase from us for life.

Q Logistics cost

AThe freight depends on weight,packing size,and your country or region,etc

Q After sales service

A Online service and we offer factory trained servicemen for machine start upoperator/maintenance training and repair service.

Q Choose mechanical equipment

A Our professional team will give you the best suggestion as long as you tell us what kind of product you need to do and the required specification

Q More question

A Please feel free to contact

A Wesupport customization.Pls feel free to tell us machiner details you wanted. You will get our reply in 24 hours

Q Delivery time

A Normally 30 days after deposit.lf the machine you need is in stock,we can ship it shortly.

Q Machine warranty

A One year.For any spare part,the customer can purchase from us for life.

Q Logistics cost

AThe freight depends on weight,packing size,and your country or region,etc

Q After sales service

A Online service and we offer factory trained servicemen for machine start upoperator/maintenance training and repair service.

Q Choose mechanical equipment

A Our professional team will give you the best suggestion as long as you tell us what kind of product you need to do and the required specification

Q More question

A Please feel free to contact

Hot Searches