- Product Details

- {{item.text}}

Quick Details

-

No-Load Speed:

-

4000rpm, 4000rpm

-

Blade Diameter:

-

85mm, 85mm

-

Warranty:

-

1year

-

Place of Origin:

-

Jiangsu, China, Jiangsu, China

-

Brand Name:

-

First Rate, First Rate

-

Frequency:

-

50Hz;60Hz

Quick Details

-

Saw Type:

-

Circular Saw

-

Rated Voltage:

-

230v;110v, 230v;110v

-

Rated Input Power:

-

550w, 550w

-

No-Load Speed:

-

4000rpm, 4000rpm

-

Blade Diameter:

-

85mm, 85mm

-

Warranty:

-

1year

-

Place of Origin:

-

Jiangsu, China, Jiangsu, China

-

Brand Name:

-

First Rate, First Rate

-

Frequency:

-

50Hz;60Hz

Product Specifications

|

Rating |

230V~50Hz/120V~60Hz |

|

No load speed |

4000RPM |

|

Blade size |

Φ85 MM |

|

Depth of cut-up |

26MM |

|

Tool length |

342x82.6x125MM |

|

Tool weight |

2.04KGS |

Features of industrial miter saw:

1.Live wire indicator.

2.Depth adjustment.

3.Extansionable Miter cut base for making precise cuts in materials up to 7/8"H X 11"W(with arm)15’’W(without arm), ideal for flooring projects.

4.Included 5 different blades enable to cut hardwood, soft wood, plastic, aluminum, metal, ceramic tile, porcelain, etc.

5.Up to 1-1/16 thick with single-hand operation.

6.Soft grip handle for comfortable extended use.

7.Cast aluminum guard with one hand release.

8.Replaceable carbon motor brushes.

Assembly and operating

This industrial miter saw is a versatile tool that is designed for use in confined work spaces. By selecting the appropriate cutting blades, it will cut copper and aluminum tubing, ceramic and marble tile, and assorted wood products. The following assembly and operating instructions will explain the tool and its operation in detail.

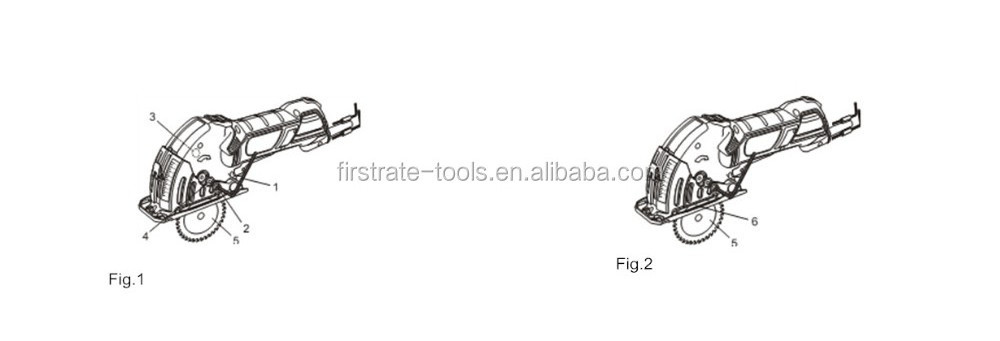

Removing the blade

1.Lay the tool on its right hand side on a workbench or other suitable work surface.

2.Insert the 5 mm hex key (1) into the arbor screw (2) on the LEFT side of the tool (Fig. 1).

3.Press inward on the spindle lock button (3) which is located on the RIGHT side of the tool.

4.Rotate the hex key CLOCKWISE while pressing on the spindle lock button until the spindle lock button engages the spindle.

5.Continue to rotate the arbor screw in a CLOCKWISE direction until the arbor screw is removed and the thick arbor washer (4) can be pulled off the arbor.

6.Turn the industrial miter saw to its upright position and carefully remove the blade (5) through the slot in the bottom of the blade guard.

Selecting the correct blade

Before installing a blade into the tool, it is important to select the correct blade for the type of material being cut.

Installing a blade

1.Remove the existing blade (if one is installed), arbor screw and thick arbor washer as noted on the previous page.

2.Slide blade (5) through the slot in the bottom of the blade guard and onto the arbor so the hole in the blade (6) slides over the arbor (Fig. 2).

3.Re-install thick arbor washer and arbor screw in the reverse order in which they were removed.

4.Lock the spindle using the spindle lock button and tighten the arbor screw by turning it counter clockwise.

Adjusting the cutting depth

The cutting depth is controlled by limiting the amount of blade exposed below the blade guard.

1.Loosen the depth control lever (1) by pulling it outward (Fig. 3).

2.Slide the depth control (2) upward to the desired cutting depth (3).

3.Lock the depth control in place by pressing the depth control lever inward toward the tool.

4.Press the rear of the blade guard lock button (4) and carefully pivot the blade guard (5) upward as far as it will go to expose the amount of blade required to achieve the desired depth of cut.

Installing the edge guide

The mini circular saw can be used with an edge guide for ripping materials up to 7" wide.

1.Using the 3 mm hex key provided, turn the edge guide locking screw (1) counter clockwise a few turns until the screw rises about 1/8" (Fig. 4).

2.Insert the edge guide rod (2) into the left hand edge guide mounting slot (3), through the middle locking slot (4) and through the right hand mounting slot (5).

3.Slide the edge guide foot (6) toward the tool until the desired width of cut is indicated on the scale where it meets the right hand edge of the trapezoidal window (7).

4.Tighten the edge guide locking screw.

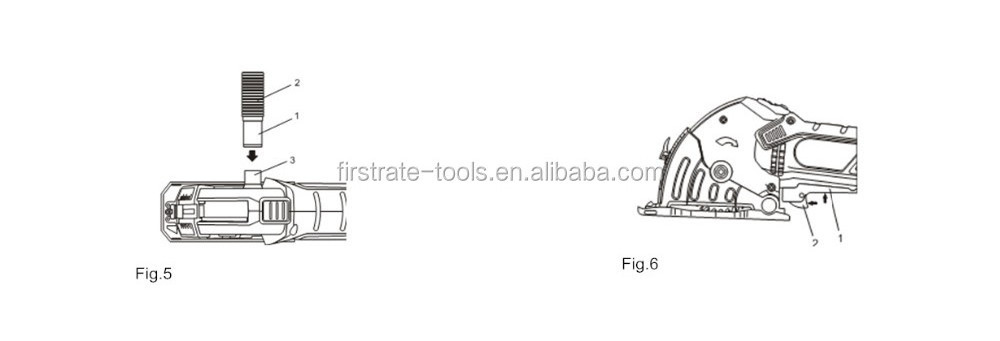

Installing the vacuum hose

The vacuum adaptor and hose can be used to attach a workshop vacuum hose to the tool. This will prevent most cutting dust from escaping into the work area.

1.Push the small vacuum connector (1) on the end of the vacuum hose (2) over the vacuum port (3) on the right hand side of the tool (Fig. 5).

2.Twist and push the vacuum connector to lock it into position.

3.Connect a workshop vacuum hose to the opposite end of the vacuum hose.

On/Off switch

This tool has dual purpose ON/OFF switch that is designed to prevent accidental starting of the tool. It also automatically turns the tool OFF then the switch is not held in the ON position.

1.To turn the saw ON, slide your index finger forward on the trigger switch (1) until it moves the lock-off trigger (2) forward.

2.While holding the lock-off trigger forward, squeeze the trigger switch to start the industrial miter saw.

3.To turn the multi-cutter OFF, release the switch trigger.

Cutting

1.Install an appropriate cutting blade in the tool as outlined on Fig. 2.

2.Adjust the cutting depth as outlined on Fig. 3.

3.Plug the tool cord into the power source.The red "power on" light (1) on the rear of the tool handle will illuminate when power is "live" (Fig. 7).

4.Place leading edge of the blade guard (2) on the workpiece to be cut (Fig. 8).

5.Grasp the tool with two hands. Place your right hand on the body of the tool (3) being careful not to cover the motor vents (4). Place your left hand on the forward part of the tool (5) so your thumb can operate the blade guard release button (6).

6.Line up front cut line indicator (7) with the cutting line marked on the workpiece (8).

7.Turn switch ON as outlined in Fig. 6 above.

8.Using the thumb on your left hand, press the blade guard release button (6).

9.Gently press downward on the front of the tool to raise the blade guard until it touches the depth control stop (9).

10.Re-check the alignment of the front cut line indicator (7) and the cutting line marked on the workpiece (8).

11.Slowly move the industrial miter saw forward until the blade touches the workpiece and begins to cut at the cutting line.

Cutting(with the edge guide)

To cut using the edge guide, follow the same basic principles as noted in Paragraphs 1 through 8 above. Instead of following a cutting line, you will simply set the edge guide at the appropriate width and hold the guide shoe (1) against the edge of the workpiece (2) to guide the blade in a straight line (Fig. 9).

Assembling the cutting&miter guide

The cutting & miter guide helps you make accurate cross cuts and miter cuts with ease.

1.Turn the cutting & miter guide (1) up side down and remove the hold-down clamp assembly (2) and the miter clamping lever (3) (Fig. 10).

2.Turn the cutting & miter guide upright and set it on a suitable workbench or table.

3.Remove the shipping wing nut (4) and thread the miter adjusting lever (3) onto the threaded bolt.

The cutting & miter guide helps you make accurate cross cuts and miter cuts with ease.

4.Rotate the inner support arm (7) away from the main housing approximately 90° and lock it in place by turning the miter adjusting lever clockwise.

5.Rotate the outer support arm (9) so it is pointing toward the operator and is parallel with the main housing.

6.Insert the hold-down clamp pin (10) into the hole (11) in the support arm, then slide the hole of the hold-down cross bar (12) onto the hold-down clamp pin.

Cutting with the cutting&miter guide

1.Assemble the cutting & miter guide as outlined in Fig. 10, 11 & 12.

2.Loosen the miter adjusting lever (3) by turning it counter clockwise (Fig. 13).

3.Rotate the inner support arm to the appropriate angle (11) and tighten the miter adjusting lever.

4.Mark a scrap workpiece with the appropriate angle. Place it against the inner support arm and resting on the outer support arm.

5.Slide the scrap workpiece under the guide rail (13) while holding it against the support arm until the cutting line is approximately 3/4" inside the guide rail.

6.Install the hold-down clamp knob and position it where it will hold the workpiece in place, then clamp the scrap workpiece to the support arm by turning the hold-down clamp knob (14) clockwise.

7.Set the cutting depth on the multi-cutter to the maximum depth.

8.Slide the blade guard into the matching grooves (15) in the cutting & miter guide until the cut line indicator in the blade guard is centered over the cutting mark on the scrap workpiece.

9.Once the workpiece is properly clamped in the cutting & miter guide, slide the blade guard into the matching grooves in the cutting & miter guide until the front edge of the blade guard is even with the workpiece.

10.While holding the workpiece with your left hand, turn the multi-cutter ON, press the industrial miter saw downward to retract the blade guard and then slide the tool forward until the workpiece is cut.

11.When the cut is complete, turn the multi-cutter OFF and allow the blade to come to a complete stop before removing the tool from the miter guide slots.

12.Remove the scrap workpiece from the cutting & miter guide and check both the cutting angle and the position of the cut relative to the cutting mark.

Replacing carbon motor brushes

The carbon motor brushes will wear down and require replacing. The time intervals between replacements will vary depending upon the type of materials being cut and the hours of use. It is recommended that the brushes be checked after each 10 hours of use. When the length of the carbon brush reaches 1/4" (6.35 mm), the brushes should be replaced.

1.Use a screwdriver and remove the screw (1) from the brush cover (2) in the left handle (Fig. 14).

2.Use a small slot screwdriver and carefully pry the brush cover out of the handle.

3.Use needle nose pliers and pull the outer spade connector (3) off the inner spade connector.

4.Use needle nose pliers to carefully lift the brush spring (4) off the carbon brush (5).

5.Pull the carbon brush from the brush holder (6).

6.Insert the new brush assembly into the motor housing.

7.Reconnect the spade connector and place the brush spring on top of the carbon brush to hold it in place.

8.Reinstall the brush cover and brush cover screw into the tool handle.

9.Repeat the above process and replace the carbon brush on the opposite side of the industrial miter saw.

.

Packed in color box or BMC