- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

860*960*1955

-

Core Components:

-

oxygen machine, Vacuum Pump, Blower, Vacuum Pump, Blower

-

Name:

-

VPSA Oxygen Generator

-

Purity:

-

80%-95%

-

Description:

-

Vacuum Pressure Swing Adsorption Oxygen Generator Plant

-

Advantage:

-

Enviromental Friendly

-

After-sales Service Provided:

-

Video and online technical support

-

Oxygen Yield:

-

80NM3/H - 10000NM3/H

-

Operating Pressure:

-

0.1-0.7bar

-

Power Supply:

-

380V/220V/50Hz or customized

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Cryo Chains

-

Production Rate:

-

80NM3/H - 10000NM3

-

Voltage:

-

380

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

860*960*1955

-

Core Components:

-

oxygen machine, Vacuum Pump, Blower, Vacuum Pump, Blower

-

Name:

-

VPSA Oxygen Generator

-

Purity:

-

80%-95%

-

Description:

-

Vacuum Pressure Swing Adsorption Oxygen Generator Plant

-

Advantage:

-

Enviromental Friendly

-

After-sales Service Provided:

-

Video and online technical support

-

Oxygen Yield:

-

80NM3/H - 10000NM3/H

-

Operating Pressure:

-

0.1-0.7bar

-

Power Supply:

-

380V/220V/50Hz or customized

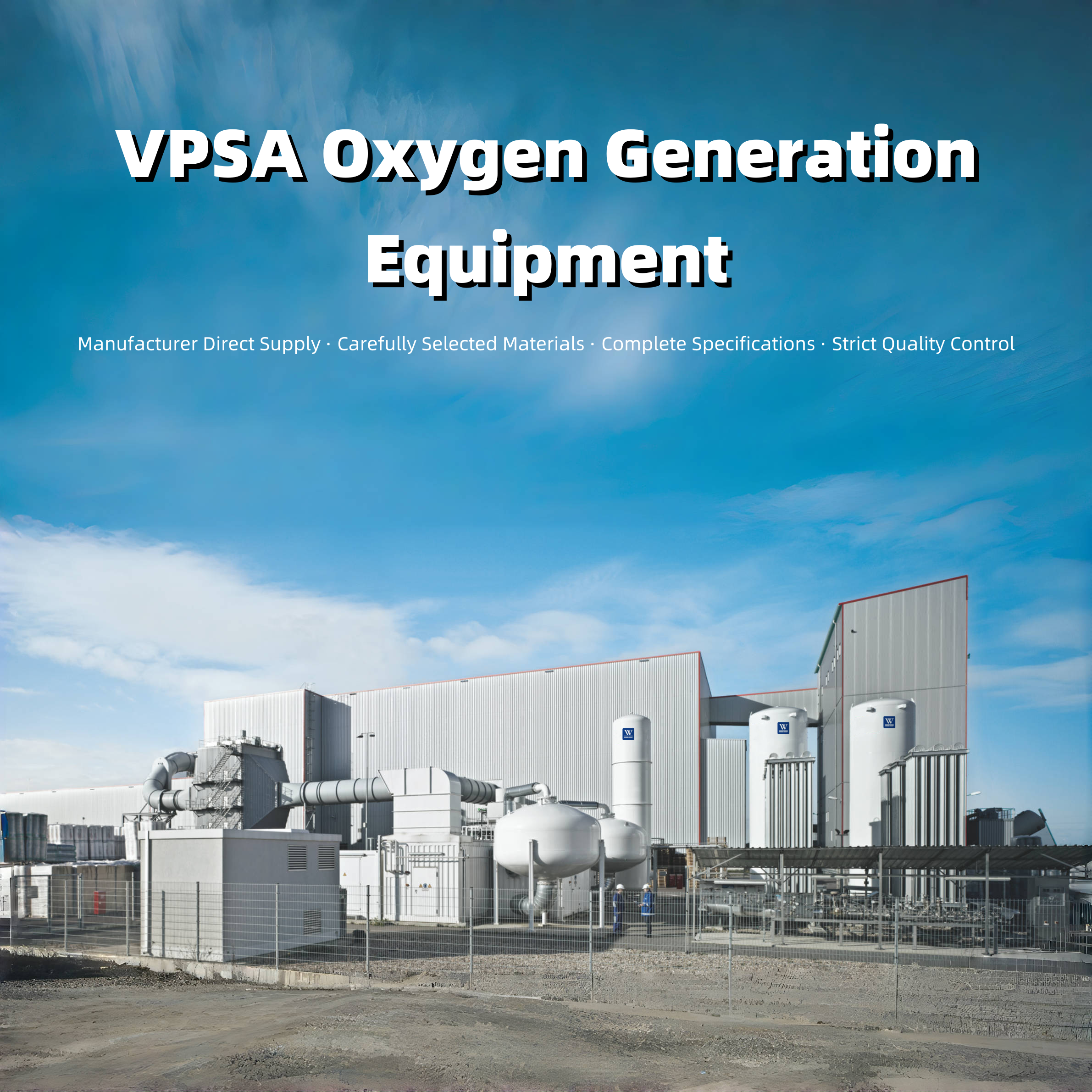

VPSA Vacuum Pressure Swing Absorption Oxygen Generator Plant

Best Selling 90% Purity Oxygen Manufacturing Plant Molecular Sieves Zeolite Central VPSA Oxygen Generating System

Our oxygen generator plants are based on a reliable, flexible and trouble-free vacuum pressure swing adsorption (VPSA) process. They are the perfect fit for on-stream applications that require low-cost gaseous oxygen with purity levels of 90 to 95 percent per volume. The capacity ranges from around 300 Nm³/h up to 10,000 Nm³/h, either as pre-engineered, fully standardised and containerised VPSA plants or customizes VPSA plants.

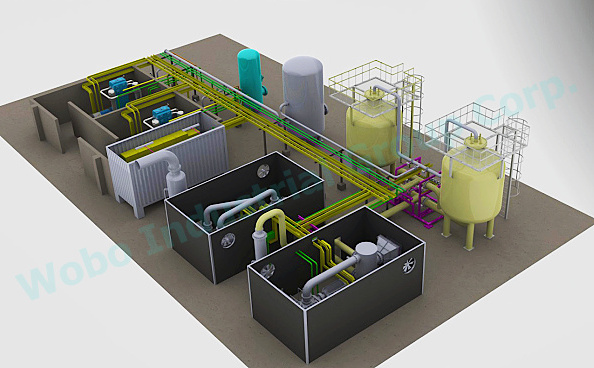

Process Description

Vacuum Pressure Swing Adsorption

oxygen production device, under normal temperature conditions, the use of molecular sieve selective adsorption of nitrogen in the air, reduce the adsorption tower pressure to desorption adsorption of nitrogen in molecular sieve, so as to achieve adsorption - desorption cycle operation, continuous production of purity of 80%~95% or more oxygen.

1.

Filtered air is blown into adsorption towers A or B containing molecular sieve and activated alumina. Nitrogen molecules are absorbed by the molecular sieve, while oxygen molecules and argon atoms pass through to the buffer tank.

2.

When one tower reaches saturation, the inlet valve closes, and oxygen-rich air is used to wash the other tower. Vacuum pump removes nitrogen from the tower.

3.

After vacuuming, oxygen-rich air and buffer tank gas wash the molecular sieve to desorb nitrogen. Tower is then filled with product gas, ready for the next adsorption cycle.

Product Parameter

|

Oxygen Yield:

|

80NM3/H - 10000NM3/H

|

|

|

|

||||

|

Oxygen Purity:

|

80%-95%

|

|

|

|

||||

|

Operating Pressure:

|

0.1-0.7bar

|

|

|

|

||||

|

Power Supply:

|

380V/220V/50Hz or customized

|

|

|

|

||||

|

We can do customization according to your needs

|

|

|

|

|

||||

Products Details

Project Case

Product Application

As an important energy gas in industrial production, oxygen is widely used in glass, papermaking, metallurgy, chemical industry, environmental protection and other industries.

Related Products

Hot Searches