- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LJXH

-

Weight:

-

0.5 KG

-

Working Temperature Range:

-

0 - 250 ℃

-

Name:

-

Brand 100% new silicone heating pad

-

Color:

-

Orange

-

Power:

-

According to the Volatage

-

Custom made:

-

Accept

-

Maximum temperature resistance:

-

250 ° C

-

Maximum temperature:

-

200 ° C

Quick Details

-

Type:

-

Flexible Heater

-

Power Source:

-

Electric

-

Voltage:

-

12V24V110V220V, 5V/12V/24V/36V/48V/110V/220V/380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LJXH

-

Weight:

-

0.5 KG

-

Working Temperature Range:

-

0 - 250 ℃

-

Name:

-

Brand 100% new silicone heating pad

-

Color:

-

Orange

-

Power:

-

According to the Volatage

-

Custom made:

-

Accept

-

Maximum temperature resistance:

-

250 ° C

-

Maximum temperature:

-

200 ° C

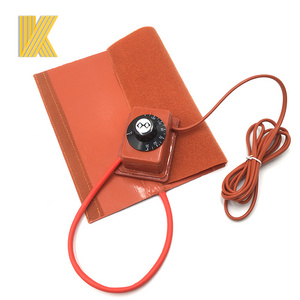

LJXH Custom Shape Silicone Rubber Heater Flexible Heating Element Silicone Heating Pad With Temperature Controller

Specifications:

The silicone rubber heater is mainly composed of nickel chromium alloy electric heating wire and silicone rubber high-temperature insulation layer. The silicone rubber high-temperature insulation layer is a thin sheet (with a thickness of about 1.8mm) composed of silicone rubber and glass fiber cloth. The silicone rubber heater has good flexibility. It has fast heating, uniform temperature, high thermal efficiency, high strength, convenient use, long safety life, is not easy to age, and can be in close contact with the heated object. The heating element is processed with nickel chromium wire or nickel alloy alloy foil, with a conventional heating power of 0.5W/cm2 and a customized heating power range of 0.1-1.2W/cm2

Silicone rubber heating plate (silicone rubber heating plate) is a thin sheet that generates heat when energized, with a standard thickness of 1.8mm. The heating element is made of nickel chromium wire or etched into a certain shape with nickel chromium foil with a thickness of 0.05 mm~0.10mm. The two layers are made of thermal insulation material, which is formed by high-temperature molding and aging heat treatment, thus having high reliability.

The silicone rubber heating plate is a soft red or orange sheet that can tightly adhere to various curved surfaces. It can be made according to various shapes and powers, which technically breaks through the hard shortcomings of traditional heaters. It can be more convenient to get close to the heated object, and the shape can change according to requirements.

Product material: silicone rubber

Maximum temperature resistance: 250 ° C

Maximum temperature: 200 ° C

Insulation resistance: ≥ 10.0MQ

Pressure resistance strength: 2000v/5s

Power deviation: ± 5%

Rated voltage: ± 5%

Maximum length: 20000mm

Normal thickness: 1.5-1.8mm

Product features:

Ø Fast heating speed, high thermal efficiency, and strong plasticity

Ø Water resistant, acid resistant, alkali resistant, with high electrical insulation strength

High mechanical strength, mechanical pressure of 100kg/cm2.

Ø Small in size, the heating element takes up almost no space during use

Ø Easy to use, due to its insulation and no open flame, it greatly simplifies the insulation and heat insulation process.

Ø The temperature resistance range is wide, ranging from -60 ℃ to 250 ℃, which is not achievable by ordinary electrical appliances.

Ø can be made into any size and can be controlled by temperature controllers to assist in temperature regulation.

The surface of the silicone heating plate can be waterproof, but it is not completely waterproof. It can be wiped off by touching or splashing conductive liquids such as water, and cannot be put into or immersed in water.

Product Usage:

Silicone rubber heaters have a wide range of applications and can be used for mixing and insulation in humid and non explosive gas environments, industrial equipment pipelines, tanks, etc. (oil drum heaters). When in use, they can be directly wrapped around the surface of the heated object.

It can be used as an auxiliary heating for refrigeration protection and air conditioning compressors, motors, and other equipment. To protect chassis, outdoor electronic devices, communication equipment, industrial ovens and thermal processing equipment, laminating equipment, experimental instrument container heating, mobile phone screen removal, thermal development of imaging equipment, locomotive fuel tank, oil pan heating and preheating, in cold and humid environments.

Temperature control method:

Constant temperature control (thermal protector): 0 degrees, 5 degrees, 10 degrees... 180 degrees or more (non adjustable temperature, automatically power-off and cooling when reaching the temperature, reset and heating, and repeat this process, with average accuracy and large temperature difference)

Mechanical knob temperature control: adjustable range 0-60 ℃, 30-110 ℃, 0-120 ℃, 30-150 ℃, 50-200 ℃ (temperature control accuracy is average, not suitable for low temperature control or high-precision control)

Intelligent digital temperature control: Room temperature -250 degrees adjustable (temperature control accuracy ± 1 degree, fluctuation within ± 3 degrees)

With temperature measurement line: K-type thermocouple, PT100 thermistor, thermistor 100K, 10K can be configured, making it convenient for customers to connect their own temperature controller for use.

Fixation method of heater:

Flat usage: fixed with imported 3M high-temperature resistant adhesive, fixed with perforated screws (customized), and fixed with liquid high-temperature resistant silicone

Curling usage: fixed with stainless steel springs, fixed with perforated zip ties on both sides, fixed with Velcro and other methods