- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

2100*1300*3300cm

-

Weight:

-

3000 KG

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Printing material:

-

Label.Non-woven Fabric. Paper. Film.OPP.PE.BOPP.PE.NY.PET.CPP

-

Product name:

-

1-8 Colors Flexographic Printing Machine

-

Function:

-

Multi Color Bag Printing Machine

-

Name:

-

Flexo Printing Press Machine

-

Suitable material:

-

Paper Film Non Woven

-

Keyword:

-

Thermal Paper Roll Printing Machine

-

Model:

-

HNB4-1200

-

Anilox roller:

-

Ceramic Anilox Roller

-

Doctor blade:

-

Single Dotor Blade

Quick Details

-

Place of Origin:

-

ZHE

-

Brand Name:

-

Havesino

-

Voltage:

-

380V

-

Dimensions(L*W*H):

-

2100*1300*3300cm

-

Weight:

-

3000 KG

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Printing material:

-

Label.Non-woven Fabric. Paper. Film.OPP.PE.BOPP.PE.NY.PET.CPP

-

Product name:

-

1-8 Colors Flexographic Printing Machine

-

Function:

-

Multi Color Bag Printing Machine

-

Name:

-

Flexo Printing Press Machine

-

Suitable material:

-

Paper Film Non Woven

-

Keyword:

-

Thermal Paper Roll Printing Machine

-

Model:

-

HNB4-1200

-

Anilox roller:

-

Ceramic Anilox Roller

-

Doctor blade:

-

Single Dotor Blade

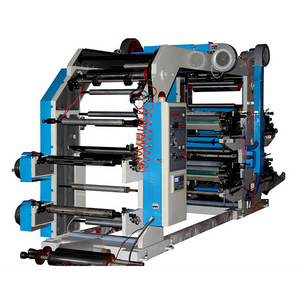

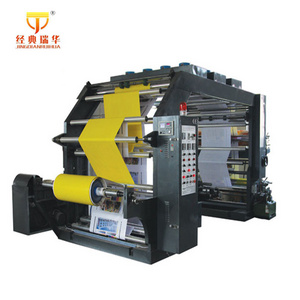

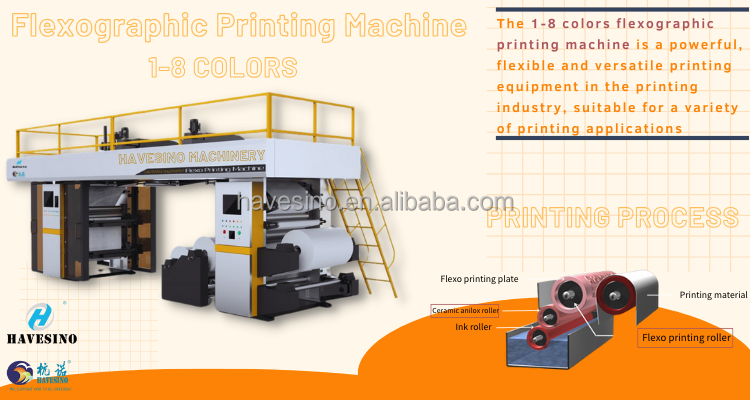

HNB4-1200

Stack Type Flexo Printing Machine

A flexographic (flexo) printing machine is a type of printing press of HAVESINO MACHINERY that uses flexible rubber or polymer printing plates to transfer ink onto a substrate. It is commonly used for printing on various materials, including packaging materials like labels,cardboard, plastic, flexible film, towel, tissue paper and more.

Application

The

stack flexographic printing machine

is a multi-functional printing equipment suitable for printing various types of materials. Here are some examples of materials that

stacked flexo printers

are typically capable of printing:

Paper: including various glossy papers, offset papers, coated papers, thermal paper etc.

Film: Plastic film, such as polyethylene (PE), polypropylene (PP), polyester (PET), etc.

Composite: A composite film or paper composed of different materials, such as aluminum foil.

Textiles: Some laminated flexographic printing machines can be used to print textiles, such as cloth or nonwovens.

Metallic materials: Some printers may be able to print on metal sheets, such as aluminum foil.

Label materials: Suitable for label printing, including various label papers and films.

Packaging materials: Used for printing various packaging materials, such as cartons, paper bags, etc.

Multi color flexo printing machine operated in our client's workshop:

A flexographic (flexo) printing machine

is a type of printing press that uses flexible rubber or polymer printing plates to transfer ink onto a substrate. Here's a brief introduction to key aspects of a flexo printing machine:

Plate Material:

*

Flexo printing equipment

uses flexible printing plates made of rubber or photopolymer. These plates are mounted on cylinders to transfer ink to the substrate.

Flexo printing is popular for various applications, including flexible packaging, labels, newspapers etc.

Ink Application:

* The engraved cells on the anilox roller control the amount of ink applied to the plates.

The ceramic anilox roller is a vital part of flexographic printing machines, ensuring precise ink transfer for consistent and high-quality prints. Known for durability and wear resistance, it's ideal for industries like labels and packaging.

Drying:

*Depending on the ink used, a drying or curing process is employed in the 1-8 colors flexo printing machine.

Flexo printer's hot air drying:

Rapidly dries ink for efficient and high-speed printing.

UV curing and solvent evaporation are common methods to ensure the ink sets properly on the substrate.

|

Width of Printing:

|

1160mm

|

|

Machinery Speed:

|

10-110m/min

|

|

Thickness of Plate:

|

2.38mm、1.7mm

|

|

Length of Printing:

|

200-1100mm

|

|

Machine Weight:

|

6000KG

|

|

Machine Dimension:

|

5.6*2.2*2.6m

|

Differences between stack-type flexo and regular flexo printing machines:

The main differences between

stack-type flexo printing machines and regular flexo printing machines

lie in their printing methods and structural designs. Here are some key distinctions:

Printing Method:

Regular Flexo Printing Machine

: Adopts direct printing, with minimal interaction between color channels.

Stack-type Flexo Printing Machine

: Utilizes stack printing, allowing the overlay of multiple color channels in the same position. This method enhances color richness and accuracy.

Number of Color Layers:

Normal Flexo Printing Machinery

: Typically suitable for printing tasks with a small number of colors.

Stack-type Flexo Printer Machine

: Permits overlaying multiple colors in the same position, handling a greater number of color layers.

Printing Precision and Color Depth:

Regular Flexographic Printing Machine

: May have limitations when dealing with complex patterns and requiring higher color depth.

Stack-type Flexo Printing Press Machine

: More advantageous in handling complex patterns and achieving higher color depth due to the ability to overlay multiple colors.

Production Efficiency:

Regular Flexo Printing Press

: Suitable for simple printing tasks, offering potentially high production efficiency.

Stack-type Flexo Printer

: More efficient when handling high-end printing tasks that require multiple colors and layers.

In summary,

stack flexo printing machines

demonstrate a clear advantage in dealing with complex printing tasks requiring more colors and higher printing precision. The choice between these types of flexo printing machines typically depends on the requirements of the printing task and the production environment.

Our Product Categories

As a professional producer and supplier of advanced slitter rewinders and converting machinery. We empower businesses worldwide with precision-engineered solutions, maximizing productivity and delivering superior quality output.

Materials We Can Slit

we have machine for the below material, you can click the pictures to get what you need or contact us to get your unique slitting solutions.

About Havesino

HAVESINO is a producer and supplier of slitter rewinders and converting machinery for the packing and label industry worldwide.

HAVESINO is a leader in design,develop and build of quality high performance slitter rewinders (slitting and rewinding machines),

core cutting machines and the machine solution for flexible packing and label industry.

core cutting machines and the machine solution for flexible packing and label industry.

Our company goal is to support you to be different. Havesino strives to show you different made-in-China products.

With professional knowledge, meticulous service, market information, and reasonable price, we can support and assist your further success.

Today, Havesino's focus is designing, manufacturing, and servicing the highest-quality slitter rewinders and other auto machinery in the world. Selling the machine is not the end of the deal! Our faith is that a sale is never final without a commitment to service.

Today, Havesino's focus is designing, manufacturing, and servicing the highest-quality slitter rewinders and other auto machinery in the world. Selling the machine is not the end of the deal! Our faith is that a sale is never final without a commitment to service.

We are committed to the design, manufacture, and introduction of high-quality and professional machines and materials through our continual and joint efforts.We have offered OEM service since 2010, and we can make the product with customer’s specific requirements, and can custom the packaging for customer. All project will be serviced by our expertise engineer in Mechanical Engineer Department, Assembly Department, Electrical Department, Software Programming Department.We have in excess of hundreds of machine installations worldwide!

Q.:Are you a factory or trading company?

A.: We are a factory and manufacturer.

Q.:How does your factory do regarding quality control?

A.:We pay much attention on quality controlling from very beginning to the very end. Fully check and test takes before shipment.

Q.:Where is your factory located? How can I visit there?

A.:Our factory located at Hangzhou,China.You can fly to Hangzhou air port directly or take fast train from Shanghai.We will

arrange to pick you up from train station or airport.

Q.:What’s service or guarantee can you offer?

A.: One year guarantee for key parts of machine;Machine installing and worker training service;Free technical support whole

life;Material support

Q: Is the machine hard to operate?

A: Our slitter machine is easy to operate and free-installation. It can be immediately started

once the power has been connected. Besides, we still have 24*7 hours on-line service technical support to help you on any problems

on operation.

Q:Will it take long time to receive the machine?

A: The lead time will be 7 days after pre-payment has been issued. We will help to delivery the machine at the earliest.

Q:Why do I choose your machine?

A: Our machine is cost effective and lifetime technical support. We have random complaint from the older order client. The goal

of our company is to offer the client most valuable products and make a win-win result.

Q. Without professional technicians, do not know how to choose machine?

A:Our staff is all professional, if you don't know how to choose machine, we can help you select the most proper machine for you.

Q. Do not find the right machine structure to match your currently demand?

A:You can tell us what's your requirements about machine, we support customization for you to meet your demand and we will

provide full sets of solutions for you. We guarantee to solve all your needs, all you need to do is trust us and tell us your

needs.

Q.Don't have professional operator to run the lines?

A:We shipped our machine as a whole, and it is very easy to everybody to operate it, we send all manuals and videos and 7*24 hours

service to you. Everybody will learn it in 2 hours.

A.: We are a factory and manufacturer.

Q.:How does your factory do regarding quality control?

A.:We pay much attention on quality controlling from very beginning to the very end. Fully check and test takes before shipment.

Q.:Where is your factory located? How can I visit there?

A.:Our factory located at Hangzhou,China.You can fly to Hangzhou air port directly or take fast train from Shanghai.We will

arrange to pick you up from train station or airport.

Q.:What’s service or guarantee can you offer?

A.: One year guarantee for key parts of machine;Machine installing and worker training service;Free technical support whole

life;Material support

Q: Is the machine hard to operate?

A: Our slitter machine is easy to operate and free-installation. It can be immediately started

once the power has been connected. Besides, we still have 24*7 hours on-line service technical support to help you on any problems

on operation.

Q:Will it take long time to receive the machine?

A: The lead time will be 7 days after pre-payment has been issued. We will help to delivery the machine at the earliest.

Q:Why do I choose your machine?

A: Our machine is cost effective and lifetime technical support. We have random complaint from the older order client. The goal

of our company is to offer the client most valuable products and make a win-win result.

Q. Without professional technicians, do not know how to choose machine?

A:Our staff is all professional, if you don't know how to choose machine, we can help you select the most proper machine for you.

Q. Do not find the right machine structure to match your currently demand?

A:You can tell us what's your requirements about machine, we support customization for you to meet your demand and we will

provide full sets of solutions for you. We guarantee to solve all your needs, all you need to do is trust us and tell us your

needs.

Q.Don't have professional operator to run the lines?

A:We shipped our machine as a whole, and it is very easy to everybody to operate it, we send all manuals and videos and 7*24 hours

service to you. Everybody will learn it in 2 hours.

Hot Searches