- Product Details

- {{item.text}}

Quick Details

-

Function:

-

Screening\separation\sorting\sieving

-

Material:

-

Carbon Steel/ Stainless Steel 304

-

Layer(s):

-

1-4 Layers

-

Capacity:

-

50-250t/h

-

Motor:

-

Famous Brand

-

Color:

-

Customers' Request

-

Screen Mesh:

-

3-80mm

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Product name:

-

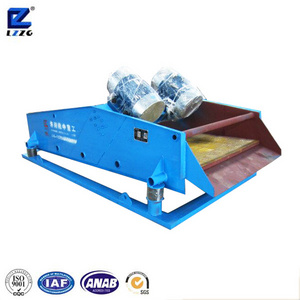

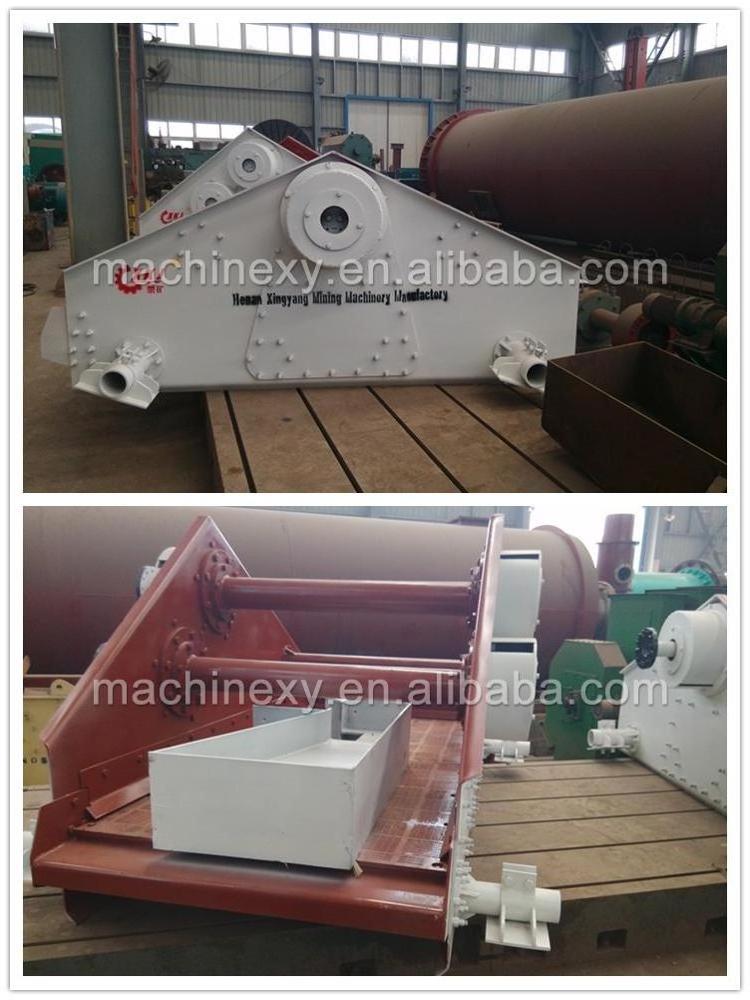

Dewatering Vibrating Screen

-

Function:

-

Screening\separation\sorting\sieving

-

Material:

-

Carbon Steel/ Stainless Steel 304

-

Layer(s):

-

1-4 Layers

-

Capacity:

-

50-250t/h

-

Motor:

-

Famous Brand

-

Color:

-

Customers' Request

-

Screen Mesh:

-

3-80mm

Vibrating dewatering screen is mainly used for dewatering of tailings in the beneficiation industry, dewatering of coal slurry in coal preparation plant, dewatering of washed quartz sand and dewatering of ceramic mud, and industrial and commercial sectors such as electricity, sugar and salt making dry and wet Grading, dehydration, de-intermediation and de-sludge. The slime recovery, the pressure filtration is coarse, the filtration is thick, the dehydration and recovery of other extremely fine materials are carried out, and the tailings are discharged in line with the thickener.

Application of Vibrating Screen

Dewatering screen is manufactured for processing the mine tailing. It is widely used in dehydrating iron ore, copper ore, gold ore, aluminum ore, etc. Simple and compact structure, low invest, high working performance, little noise and easy maintenance make it a hot screen in market.

Advantage of Vibrating Screen

1. Dehydration, de-intermediation, de-mudging, tailings dry row;

2, 45 degree filter plate at the feeding end, 0-5 degree sieve surface climbing and dehydration, increasing dewatering efficiency, water content of sieve material is as low as 8%-15 %;

3, replace a sieve plate for 3-5 minutes, increase operating efficiency;

4, large processing capacity, no hole blocking, mesh hole minimum 0.1mm;

5, 1000 hours of operation to replace the lubricating oil, the machine has a long life and low noise.

|

Model |

Screen Size (mm) |

Layers |

Mesh Size (mm) |

Feeding Size (mm) |

Capacity (t/h) |

Power (kw) |

Motor Model |

REV (r/min) |

Amplitude (mm) |

Angle (℃) |

Machine Size (mm) |

|

2YK1237 |

1200×3700 |

2 |

3-50 |

≤200 |

7.5-80 |

4-15 |

Y160L-4/15 |

970 |

8 |

20 |

4010×2250×2660 |

|

3YK1237 |

1200×3700 |

3 |

3-50 |

≤200 |

7.5-80 |

4-15 |

Y160L-4/15 |

970 |

8 |

20 |

4010×2250×3140 |

|

2YK1548 |

1500×4800 |

2 |

5-50 |

≤400 |

50-208 |

4-15 |

Y160L-4/15 |

970 |

8 |

20 |

5120×2590×3060 |

|

3YK1548 |

1500×4800 |

3 |

5-50 |

≤400 |

50-250 |

4-15 |

Y160L-4/15 |

970 |

8 |

20 |

5120×2590×3540 |

|

2YK1848 |

1800×4800 |

2 |

5-80 |

≤400 |

50-260 |

4-18.5 |

Y180M-4/18.5 |

970 |

8 |

20 |

5120×2950×3060 |

|

3YK1848 |

1800×4800 |

3 |

5-80 |

≤400 |

50-300 |

4-18.5 |

Y180M-4/18.5 |

970 |

8 |

20 |

5120×2950×3540 |

|

2YK1860 |

1800×6000 |

2 |

5-80 |

≤400 |

50-300 |

4-18.5 |

Y180M-4/18.5 |

970 |

8 |

20 |

6260×2950×3480 |

|

3YK1860 |

1800×6000 |

3 |

5-80 |

≤400 |

50-350 |

4-22 |

Y180L-4/22 |

970 |

8 |

20 |

6260×2990×3960 |