- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

DN

-

Effective Volume:

-

Various

-

Dimension(L*W*H):

-

according to different model

-

Voltage:

-

380V / 410V / 220V 50Hz/ 60Hz

-

Power:

-

10Kw-700Kw

-

Warranty:

-

one year for parts, lifetime for tank

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Design temperature:

-

240℃

-

Design pressure:

-

0.6Mpa

-

Design vacuum degree:

-

-0.098Mpa

-

Material:

-

stainless steel

-

Control method:

-

PLC computer automatic control

-

Alarm method:

-

Ultrahigh pressure automatic alarm

-

Heating method:

-

Electric heating conduction oil

-

Capacity:

-

customized

-

Color:

-

customized

-

Certification:

-

ISO CE SGS

-

Weight:

-

3t-50t

Quick Details

-

Place of Origin:

-

Shandong, China

-

Application:

-

carbonization stove

-

Brand Name:

-

LUY

-

Model Number:

-

DN

-

Effective Volume:

-

Various

-

Dimension(L*W*H):

-

according to different model

-

Voltage:

-

380V / 410V / 220V 50Hz/ 60Hz

-

Power:

-

10Kw-700Kw

-

Warranty:

-

one year for parts, lifetime for tank

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Design temperature:

-

240℃

-

Design pressure:

-

0.6Mpa

-

Design vacuum degree:

-

-0.098Mpa

-

Material:

-

stainless steel

-

Control method:

-

PLC computer automatic control

-

Alarm method:

-

Ultrahigh pressure automatic alarm

-

Heating method:

-

Electric heating conduction oil

-

Capacity:

-

customized

-

Color:

-

customized

-

Certification:

-

ISO CE SGS

-

Weight:

-

3t-50t

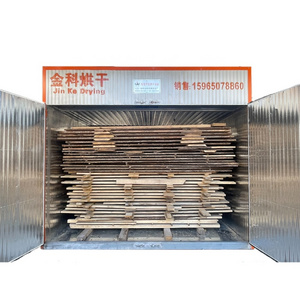

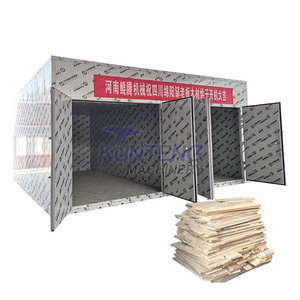

Factory price wood carbonized autoclave carbonuzing kiln dry machine

Technical Parameters:

| Model | Wood depth carbonization equipment |

| Size | The maximum diameter which our company can make is 4.5m. And the length is up to your Requirement. |

| Design temperature (℃) | 240 ℃ |

| Design pressure ( Mpa ) | 0.6Mpa |

| Working pressure ( Mpa ) | 0.3-0.4Mpa |

| Design vacuum degree ( Mpa ) | -0.098mpa |

| Material | 304 stainless steel |

| Heating method | Electric heating conducting oil cooling system |

| Cooling way | Forced circulation cooling system |

| Water way | Spray water and water vapor |

| Insulation way | External galvanized sheet, with 80mm insulation cotton |

| Heat distribution way | Circulating fan |

| Open the door way | Manual and electric dual open the door |

| Sealing method | Inflatable silicone seal (life 1--2 years) |

| Control method | PLC computer control |

| Safe method | Double-door safety interlock tank, tank three safety interlock |

| Alarm method | Ultrahigh pressure automatic alarm |

| Track label, bearing | 12th rail> 12 tons |

Advantages:

1 . Full automatic control by computer.PLC automatic computer control system to ensure accurate and reliable control, add medium circulation device to ensure uniform heat treatment, carbonization treated wood fineness uniform, no smell.

2. The frame of the equipment is made of stainless steel to prevent corrosion. Stainless steel tank, corrosion resistance, durability, processing and flexible.

3. High precision and better effect of treatment. Six sets of security system to ensure safe operation of equipment.

4 . Easy to operate, energy saving and environmental protection .

5. Using anaerobic carbonization. According carbonization needs to maintain an oxygen-free vacuum carbonized in the carbonization process, the temperature is between 160 ~ 230 ℃ adjustable.

6. Suitable for mass production of high-end wood processing enterprises.

What are the advantages of carbonized wood?

1. Strong corrosion resistance

2. Environmental Protection

3. Purifying air

4. Stability

5. Color gorgeous, change a single species of a single color

What the carbonized wood used for?

The wood flooring is one of the main purposes. In addition, It can also be used to make into other outdoor products, such as tables and chairs, swing, grape trellis, huts and others