- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.2KW

-

Min. Lifting Height:

-

205mm

-

Table Size:

-

customized

-

Overall Dimensions:

-

customized

-

Weight:

-

160 kg

-

Voltage:

-

220/380V 50/60hz

-

Color:

-

Customers' Requirements

-

Motor Power:

-

2.2KW

-

Product name:

-

Lift Table

-

Type:

-

Hydraulic Cylinder Drive

-

Usage:

-

Lifting

-

Control methods:

-

Wire/wireless control

-

Lifting speed:

-

4-6m/min

-

Main Material:

-

Q235

-

Power supply:

-

AC 110/220/230/380/415V

Quick Details

-

Warranty:

-

2 years

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PLK LIFT

-

Power:

-

2.2KW

-

Min. Lifting Height:

-

205mm

-

Table Size:

-

customized

-

Overall Dimensions:

-

customized

-

Weight:

-

160 kg

-

Voltage:

-

220/380V 50/60hz

-

Color:

-

Customers' Requirements

-

Motor Power:

-

2.2KW

-

Product name:

-

Lift Table

-

Type:

-

Hydraulic Cylinder Drive

-

Usage:

-

Lifting

-

Control methods:

-

Wire/wireless control

-

Lifting speed:

-

4-6m/min

-

Main Material:

-

Q235

-

Power supply:

-

AC 110/220/230/380/415V

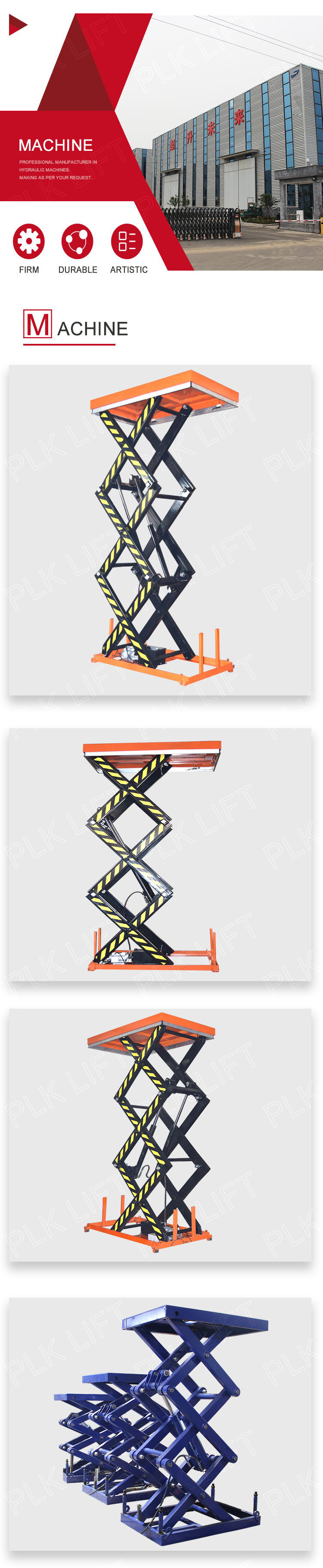

Stationary Lift Table Platform Three Scissors Lift Table

Stationary Lift Table Platform Three Scissors Lift Table

Production description

PLK Brand HW Series Scissor Lift Tables are high-quality electronic hydraulic scissor lifts with loading capacities from 1,000KG to 4,000KG, and lifting heights up to 4m. We also accept customized platform size and lifting height. I t can be installed both on the ground and in the pit.

Data-sheet

|

Model |

Load Capacity(KG) |

Self Height (MM) |

Max Platform Height(MM) |

Platform Size(MM) |

Net weight (KG) |

|

HW1001 |

1000 |

205 |

1000 |

1300×820 |

160 |

|

HW1002 |

1000 |

205 |

1000 |

1600×1000 |

186 |

|

HW1003 |

1000 |

240 |

1300 |

1700×850 |

200 |

|

HW1004 |

1000 |

240 |

1300 |

1700×1000 |

210 |

|

HW1005 |

1000 |

240 |

1300 |

2000×850 |

212 |

|

HW1006 |

1000 |

240 |

1300 |

2000×1000 |

223 |

|

HW1007 |

1000 |

240 |

1300 |

1700×1500 |

365 |

|

HW1008 |

1000 |

240 |

1300 |

2000×1700 |

430 |

|

HW2001 |

2000 |

230 |

1000 |

1300×850 |

235 |

|

HW2002 |

2000 |

230 |

1050 |

1600×1000 |

268 |

|

HW2003 |

2000 |

250 |

1300 |

1700×850 |

289 |

|

HW2004 |

2000 |

250 |

1300 |

1700×1000 |

300 |

|

HW2005 |

2000 |

250 |

1300 |

2000×850 |

300 |

|

HW2006 |

2000 |

250 |

1300 |

2000×1000 |

315 |

|

HW2007 |

2000 |

250 |

1400 |

1700×1500 |

415 |

|

HW2008 |

2000 |

250 |

1400 |

2000×1800 |

500 |

|

HW4001 |

4000 |

240 |

1050 |

1700×1200 |

375 |

|

HW4002 |

4000 |

240 |

1050 |

2000×1200 |

405 |

|

HW4003 |

4000 |

300 |

1400 |

2000×1000 |

470 |

|

HW4004 |

4000 |

300 |

1400 |

2000×1200 |

490 |

|

HW4005 |

4000 |

300 |

1400 |

2200×1000 |

480 |

|

HW4006 |

4000 |

300 |

1400 |

2200×1200 |

505 |

|

HW4007 |

4000 |

350 |

1300 |

1700×1500 |

570 |

|

HW4008 |

4000 |

350 |

1300 |

2200×1800 |

655 |

|

HD1000 |

1000 |

305 |

1780 |

1300X820 |

210 |

|

HD2000 |

2000 |

350 |

1780 |

1300X850 |

295 |

|

HD4000 |

4000 |

400 |

2050 |

1700X1200 |

520 |

|

HT1000 |

1000 |

470 |

3000 |

1700x1000 |

450 |

|

HT2000 |

2000 |

560 |

3000 |

1700x1000 |

750 |

|

HF400 |

400 |

600 |

4140 |

1700x1000 |

800 |

|

HF800 |

800 |

706 |

4210 |

1700x1000 |

858 |

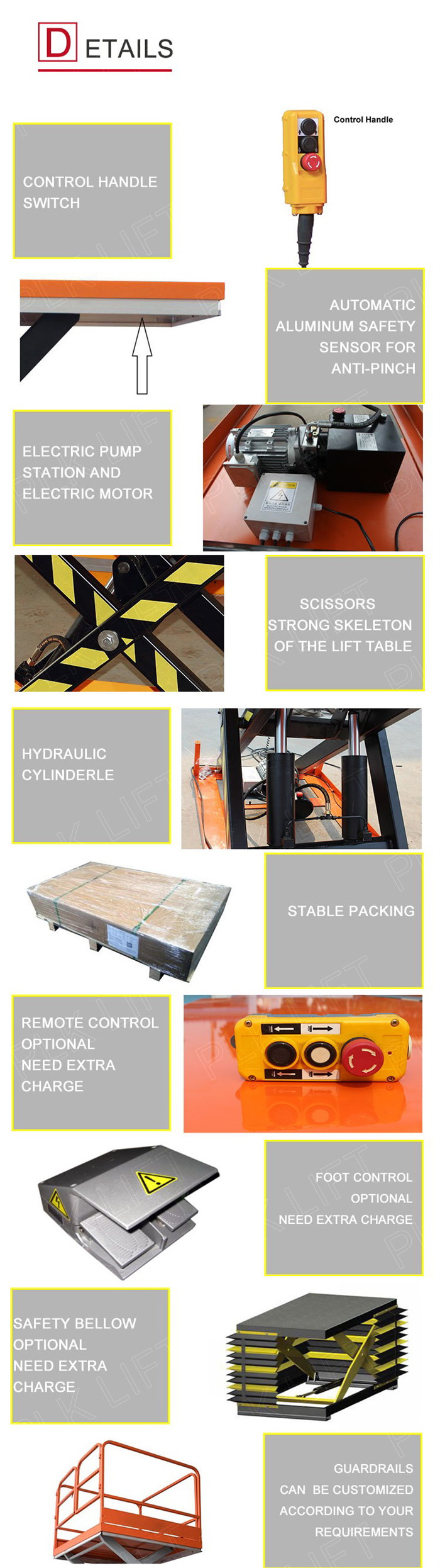

Features & Advantages :

1. Surface treatment: shot blasting and s toving varnish with anti-corrosion function.

2. High quality pump station make s scissor lift table lift s and fall very stabl e .

3. Anti-pinch scissor design; main pin-roll place adopts self-lubricating design which prolong life span.

4. Removable lifting eye to help lift the table and install.

5. Heavy duty cylinders with drainage system and check valve to stop the lift table dropping in case of hose burst.

6. Pressure relief valve prevent overload operation; Flow control valve make descent speed adjustable.

7. Equipped with aluminum safety sensor under the platform for anti-pinch while dropping.

8. Up to American standard ANSI/ASME and Europe standard EN1570

9. Safe clearance between scissor to prevent damages during operation.

10. Brief structure make it much easier to operate and maintain.

11. Stop at the per-concerted and accurate location point.

Safety Precautions:

1. Explosion-proof valves: protect hydraulic pipe, anti-hydraulic pipe rupture.

2. Spillover valve: It can prevent high pressure when the machine moves up. Adjust the pressure.

3. Emergency decline valve: it can go down when you meet an emergency or the power off.

4. Overload protection locking device: in case of dangerous overload.

5. Anti-dropping device: Prevent falling of platform.

6. Automatic aluminum safety sensor: lift platform will stop automatically when come across barriers.

Contact Information:

Sarah (Sales manager)

Jinan PLK Machinery Co., Ltd

Mob/Wechat/Whatsapp: +86-13889928667

Email: sarah(at)plklift.com