- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-70Kw depends on size

-

Dimension(L*W*H):

-

Depends on capacity

-

Weight:

-

150 KG

-

Material:

-

SUS304/SUS316/red Copper

-

Capacity:

-

50l-5000l

-

Thickness:

-

2-3mm / Inside:3.0mm Outside:2mm

-

Cooling way:

-

Dimple Plate Cooling

-

Insulation:

-

Thickness=80mm~100mm

-

Type:

-

Coolers

-

Inner Polishing Precision:

-

0.4-0.6 Micrometer

-

Control method:

-

Temperature Control

-

Name:

-

Beer Commercial Beer Brewing Equipme

-

Heating method:

-

Electricity Steam Fire

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

ZH

-

Voltage:

-

customized

-

Power:

-

15-70Kw depends on size

-

Dimension(L*W*H):

-

Depends on capacity

-

Weight:

-

150 KG

-

Material:

-

SUS304/SUS316/red Copper

-

Capacity:

-

50l-5000l

-

Thickness:

-

2-3mm / Inside:3.0mm Outside:2mm

-

Cooling way:

-

Dimple Plate Cooling

-

Insulation:

-

Thickness=80mm~100mm

-

Type:

-

Coolers

-

Inner Polishing Precision:

-

0.4-0.6 Micrometer

-

Control method:

-

Temperature Control

-

Name:

-

Beer Commercial Beer Brewing Equipme

-

Heating method:

-

Electricity Steam Fire

200L fermenting equipment beer stainless steel fermentation tanks fermenter

Fermentation System

T he fermentation tank adopt cooling jacket and two-stage cooling refrigerant control mode at the cone and cylinder. So such design and cooling method to control the flow of the cooling liquid state in fermentation tank by the size of the two-stage cooling refrigerant flow. It will improve heat transfer efficiency and cooling rate, faster cooling, and reduce cooling costs and high economic efficiency equipment commercial operation.

1. Total volume:250 L

2. Effective volume:2 00L

3. Material: S tainless steel

4. Outer TH:2mm

5. Inner TH:3mm

6. Insulation TH:8 0 mm

7. Top type:Domed top

8. Insulation material:PU

9. CIP pipe Diameter:Φ32mm

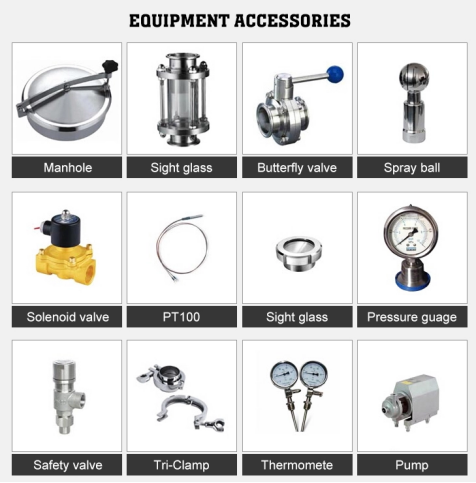

10. CIP ball :Rotating spray ball

11. Sewage outlet: Φ38mm

12.Refrigerant import/export: Φ32mm

13.Thermometer blind: Φ8mm

14. Sampling valve:Φ 32 mm

15. R espiration valve : Φ38mm

16.Pressure gauge:Φ32mm

17.Mechanical and electronic pressure regulating valve:Φ32mm

18.Working pressure: 0.15mpa, experimental pressure: 0.2mpa

l Carbon dioxide charging device is added to store beer

l Single tank single control

Zunhuang series mash system consist of 1 vessel mash system, 2 vessels mash system, 3 vessels and other design, mainly includes mash tank, brew kettle, lauter tank and whirlpool. The main part of equipment in this system are made of SUS304, SS316 reaching international standard level.(Zunhuang company also can customized high quality copper equipment according to user place.)

Now Zunhuang equipment adopt electric heating, steam heating, direct fire heating method on mash heating system, it’s Zunhuang researched by the many years of practical experience and combined with the different situations of customers. It will be used in hotel, beer bar, and teaching.

1. After-sale Service for the whole life.

2. 24h service for you, solve your urgent problem first time.

3. 3 years warranty for the main products.

4. Free design for your brewery layout for 2D or 3D.

5. Spare parts replacement and repair service provided.

6. Engineer going abroad for installation, debugging and technical training if you need.

7. Provide the Form E, CO, etc..others necessary reduce import Tax files for you.

8. To provide update information about brewing equipment technology once we test.

9. Help you send the goods if you have others company order, then send to you together.

10. Door to Door service, if you need any brewing parts.

1. Ocean shipment,railway shipment,express delivery.

2. No matter flat pack to save shipping cost,or fill with your merchandise into allassembled displays to ship together,all is up to you.

3. And we have our own department to arange the shipments.we ship worldwide dierctly by see,railway or express.we will provide all documents you need to import.

4. We packed the goods to meet the transport distance, shock, rust and anti-handling requirements damaged before shipping, to ensure the safe transport of goods to reach the buyer designated location before it is shipped.