- Product Details

- {{item.text}}

Quick Details

-

Material:

-

ASTM A732 8Q,42CrMo,G-42CrMo4 Alloy Steel, etc.

-

Manufacturing Process:

-

Lost Wax Casting Parts;Heatment;Precision Machining

-

Casting Tolerance:

-

CT7 to CT9

-

Heat Treatment:

-

Normalizing, Quenching+Tempering, Gaseous Nitrocarburizing

-

Application:

-

Agricultural machinery parts& Engineering machinery parts

-

OEM:

-

Acceptable

Quick Details

-

Place of Origin:

-

Shanxi, China

-

Model Number:

-

Steering Arm Spindle

-

Name:

-

Steering Arm Spindle

-

Material:

-

ASTM A732 8Q,42CrMo,G-42CrMo4 Alloy Steel, etc.

-

Manufacturing Process:

-

Lost Wax Casting Parts;Heatment;Precision Machining

-

Casting Tolerance:

-

CT7 to CT9

-

Heat Treatment:

-

Normalizing, Quenching+Tempering, Gaseous Nitrocarburizing

-

Application:

-

Agricultural machinery parts& Engineering machinery parts

-

OEM:

-

Acceptable

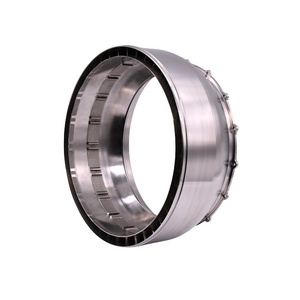

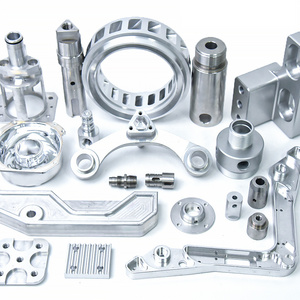

OEM Agricutural Machinery Parts Steering Arm Spindle

Products Description

|

Product Name

|

Steering Arm Spindle

|

|

Oem

|

Acceptable

|

|

Materials

|

ASTM A732 8Q,42CrMo,G-42CrMo4 Alloy Steel, etc.

|

|

Manufacturing

Process |

Lost Wax Casting Parts;Heatment;Precision Machining

|

|

Castingtolerance

|

CT7 to CT9

|

|

Heat Treatment

|

Normalizing, Quenching+Tempering, Gaseous Nitrocarburizing

|

|

Test Item And Method

|

Chemical composition: Spectrum Analysis;

Hardness:HRC/HV Mechnical property: Tensile Test Internal defect: RT Form and position tolerance detection: CMM |

|

Application

|

Agricultural Machinery parts& Engineering machinery parts

|

|

Package

|

Plywood case

|

OEM / ODM Request Is Very Welcome!

Production Process

Steering arm spindle is produced and used by a pair of left and right parts, we produce them for GKN, they would be finally used for JOHN DEER equipments.

Steering arm spindle used Sodium silicate process which can not only guarantee the product’s precision and quality, but also can control production cost. Wax injection by machine will improve the production efficiency, save production cost and ensure the consistency of wax mold quality, also the shell made by production line can increase production capacity and reduce production costs,thus it will improve the consistency of shell shape.

Steering arm spindle uses quenching + tempering and Gaseous Nitrocarburizing to ensure high toughness and hardness. Meanwhile, we use black Gaseous Nitrocarburizing to protect against corrosion and meet the requirements of the corresponding salt spray test.

Steering arm spindle uses CNC to guarantee product’s size precision. We have strong machining capability, like Turning, Milling,Grinding, Broaching, Tapping, Drilling, Reaming and other process to meet the processing of various high-precision products efficiently.

Inspection

We use spectrum to detect the chemical composition of castings timely and accurately, we can also test the mechanical properties, including tensile strength, yield strength, elongation, impact work and various types of hardness test: HB, HRC, HV, etc.

Magnetic powder test and Liquid penetration detection for Steering arm spindle are used to ensure the surface quality of

casting,meanwhile we’ll cut the part and use Ray Test to guarantee internal quality of casting.

We use CMM, Projector and various gauges and tools to monitor the size precision efficiently.

We are in accordance with the requirements of customers to carry outtests for a variety of technical parameters of the

product,we also have our own Inspection management system that check the technical specifications efficiently in production, to make the products we delivered will be satisfied by our customers.

Product Packaging

We’ll design the suitable package according to different products, that’ll be the most economic, effective and the most safest.

Molds

Mold is the key of castings which is designed and manufactured by our technical team and professional mold manufacturer. When design the mold, our mold engineer will perform the simulation casting, it will improve the product qualification ratio greatly. Meanwhile, multiple cavities will reduce the tooling costs even more.

Hot Searches