- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

14500 KG

-

Application:

-

Stone Powder Grinding

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Usage:

-

Grinding Mining Stone

-

Quality:

-

Advanced Technology

-

After sale service:

-

Engineer Avalable

-

Advantages:

-

High Efficiency Low Energy

-

Grinding material:

-

200+ Materials

Quick Details

-

Capacity(t/h):

-

2-6

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KELEFU

-

Weight:

-

14500 KG

-

Application:

-

Stone Powder Grinding

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Usage:

-

Grinding Mining Stone

-

Quality:

-

Advanced Technology

-

After sale service:

-

Engineer Avalable

-

Advantages:

-

High Efficiency Low Energy

-

Grinding material:

-

200+ Materials

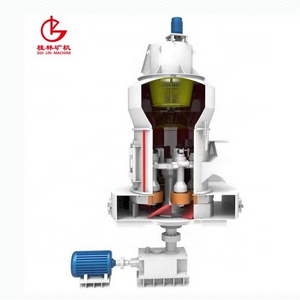

Coal gangue raymond mill grinding mill raymond mill cement grinding set grinding

Raymond mill is composed of main machine, analyzer, fan, finished product cyclone separator, micro powder cyclone separator and air duct. Among them, the main machine consists of a frame, an air inlet volute, a blade, a grinding roller, a grinding ring, and a cover. Raymond mill is suitable for small and medium-sized mining, chemical industry, building materials, metallurgy, refractory materials, glass, cement and other industries. Raymond mill is widely used in metallurgy, building materials, chemical industry, mining and other fields for grinding and processing of industrial and mining product materials. Raymond mill is suitable for processing various non-flammable and explosive minerals with Mohs hardness below level seven. Raymond mill is widely used in marble, limestone, dolomite, High-fine milling processing of more than 280 kinds of materials in barite, calcite, potassium feldspar, talc, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass, insulation materials and other industries .

♥

1. The three-dimensional structure of the

Raymond mill

covers a small area and is highly complete. It forms an independent production system from lump materials to finished powder.

♥

2. The finished powder has uniform fineness and a sieving rate of 99%, which is difficult to achieve with other grinding equipment.

♥

3. The main transmission device of the

grinding mill

adopts a closed gear box and pulley, which ensures smooth transmission and reliable operation.

♥

4. The important parts of

Raymond mill

are all made of steel, and the wear-resistant parts are all made of high-performance wear-resistant materials. The whole machine has high wear resistance and reliable operation.

♥

5. The electrical system adopts centralized control, and the grinding workshop can basically realize unmanned operation and is easy to maintain.

Ore type:

Heavy calcium carbonate: limestone, calcite, marble, dolomite, etc.

Barite, potassium feldspar, albite, talc, fluorite, mullite, paraffin, sepiolite, manganese ore, copper ore, iron ore, molybdenum ore, antimony ore, marquise, calcite , Quartz stone, volcanic stone, malachite, harzburgite, weathered stone, aluminum ore, zircon stone, quartz sand, vein ore, mica stone, tin ore, scheelite, diabase, ilmenite, sandy tin Mine, gangue, magnesium ore, medical stone, phosphate rock, shale, silica, wollastonite, brucite, hydrated lime, mullite, paraffin stone

Minerals

:

Bauxite, bentonite, kaolin, white clay, loess, clay, gypsum, graphite, cement, double fly powder, white powder, titanium dioxide, pottery clay, porcelain clay, magnesium iron oxide, chromium oxide green, attapulgite, barium salt, glass, thermal insulation Material

Solid fuel pulverization:

Lignite, humic acid, blast furnace coal injection, petroleum coke, carbon blocks, carbon, etc.

Special categories:

Activated carbon, pig iron pins, cassava, tungsten bars, coconut shells, charcoal, chemical raw materials, shellfish, etc.

Power plant desulfurization limestone powder making;

Slag micron powder processing;

Grinding projects in building materials, chemical industry, metallurgy and other industries.

The structure of Raymond mill mainly consists of a host machine, an analyzer, a fan, a finished cyclone separator, a powder cyclone separator and an air duct. Among them, the main machine consists of a frame, an air inlet volute, a blade, a grinding roller, a grinding ring, and a cover. Manufacturer supplies Raymond mill , large complete set of gypsum mill, pulse micro powder Raymond mill equipment.

The materials to be crushed are added into the machine from the feed hopper on the side of the machine casing, and rely on the grinding roller device suspended on

the plum blossom frame

of the main machine to revolve around the vertical axis and at the same time rotate on its own. Due to the centrifugal force during rotation, The grinding roller swings outward and presses against the grinding ring, causing the blade to scoop up the material and send it between the

grinding roller

and the

grinding ring

. The rolling and crushing of the grinding roller achieves the purpose of crushing the material.

Air separation process: After the material is ground,

the fan blows

the wind into the main casing, blowing up the powder, which is sorted by

the analyzer

placed above the grinding chamber. Materials that are too fine and too coarse fall into the grinding chamber for regrinding. The powder that meets the specifications enters the

cyclone collector

with the wind flow, and is collected and discharged through the powder outlet, which is the finished product. The air flow returns to the fan from the return duct at the upper end of the large

cyclone collector

. The air path is circular and flows under negative pressure. The increased air volume in the circulating air path is discharged through the exhaust pipe between the fan and the host machine and enters the small

cyclone collection

device for purification.

| Model | KL500 | KL650 | KL780 | KL980 | KL1100 | KL1450 | KL1760 | KL1950 | KL2100 |

| Capacity (t/h) | 0.5-2 | 0.5-2.5 | 1-3 | 1.5-4 | 2-6 | 6-10 | 8-20 | 8-20 | 20-40 |

| Main engine motor power(kw) | 7.5 | 15 | 18.5 | 30 | 45 | 90 | 132 | 185 | 220 |

| Fan motor power(kw) | 5.5 | 11 | 15 | 22 | 37 | 90 | 132 | 185 | 220 |

| Analyzer motor power(kw) | 1.1 | 1.1 | 2.2 | 2.2 | 5.5 | 7.5 | 22 | 37 | 45 |

| Main shaft speed(r/m) | 120 | 120 | 120 | 120 | 120 | 90 | 90 | 90 | 90 |

| Diameter of Grinding ring(mm) | 500 | 650 | 780 | 980 | 1100 | 1450 | 1760 | 1950 | 2100 |

| Diameter of grinding roller(mm) | 150 | 180 | 260 | 300 | 320 | 400 | 450 | 570 | 630 |

| max.feed size(mm) | 15 | 15 | 15 | 20 | 25 | 30 | 30 | 40 | 40 |

| Final size(mm) | 1.6 ------ 0.045 | ||||||||

| Weight(t) | 1.8 | 2.8 | 3.8 | 6.5 | 14.5 | 26 | 48 | 65 | 85 |

Wearing parts of Raymond mill : The wearing parts refer to the grinding tools, including the grinding roller, grinding ring, shovel, plum blossom frame, etc.;

Parts of Raymond mill : Machine shell, connecting pipe, large hoist (collector), dust collector, frame, rubber sleeve, all kinds of bearings, grinding roller, center shaft, diverter plate (air duct), volute, analytical disk, vertical shaft, horizontal shaft, connecting flange, dust bag, triangle belt, belt pulley, etc., these are the parts of Raymond mill, but do not need to be replaced often, only if the fault is replaced.

Q1: Are you factory or trade company?

A1: We are factory with CE. We have factory in China.

Q2: Where your products have been exported before?

A2: Our products have been sold to South Asia, Africa, South America, middle East and so on.

Q3: How will you help the customer to install the equipment?

#1 Our senior engineer will supply installation and training service on-line or on-site .

#2 We have engineer in Uganda ,Sudan ,Kenya ,China, We will supply 7*24 service .

Q4: How about the wear parts supply?

A4: We will supply the wear parts with factory price . You can buy them from our factory in China.

Q5: What about after-sale service?

A5:12 months warranty for all kinds of products.

Q6: How to get the free solution and quotation ?

A6: Please send inquiry to us ,leave your whatsapp and email , our sales manager will contact you within 1 hours .