- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Power:

-

125W

-

Weight:

-

45

-

Applicable Industries:

-

laboratory, Chemical Room, institute

-

Product name:

-

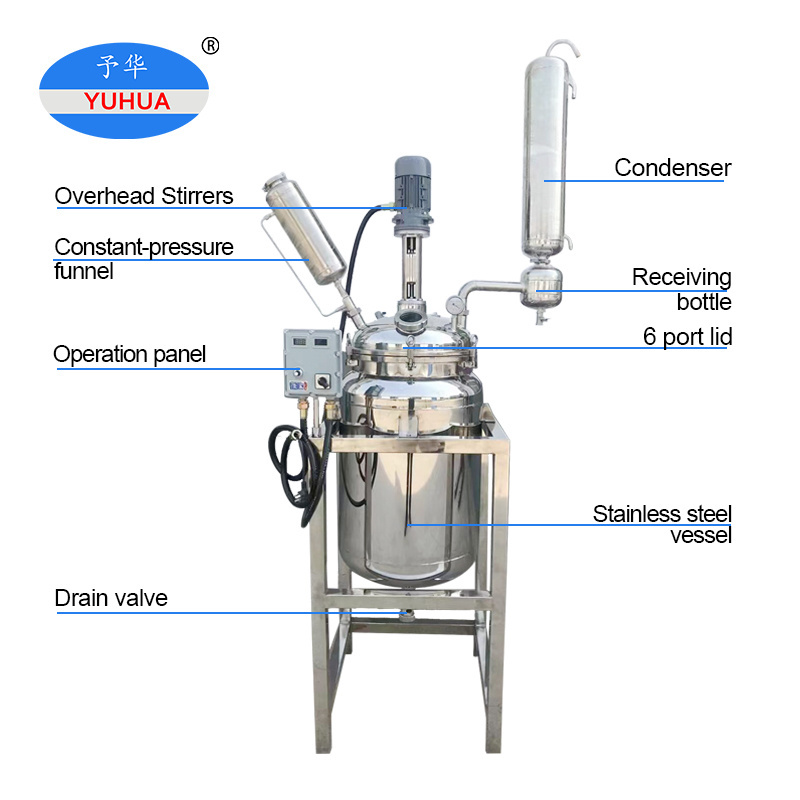

tank stainless steel 100l chemical reactor

-

Application:

-

Chemical Testing Research

-

Glass Material:

-

Borosilicate Glass 3.3 (GG-17)

-

Material:

-

SUS304

-

Function:

-

Reaction Process

-

Feature:

-

Laborotary

-

Structure:

-

Lateral Rotation

-

Machine type:

-

Chemical Batch Reactor

-

Agitator:

-

Impeller

-

Reaction Flask:

-

50-200L

Quick Details

-

Capacity:

-

0.1L/0.25L/0.5L/1L/2L/3L/5L/10L/20L/30L

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUHUA

-

Voltage:

-

220V

-

Power:

-

125W

-

Weight:

-

45

-

Applicable Industries:

-

laboratory, Chemical Room, institute

-

Product name:

-

tank stainless steel 100l chemical reactor

-

Application:

-

Chemical Testing Research

-

Glass Material:

-

Borosilicate Glass 3.3 (GG-17)

-

Material:

-

SUS304

-

Function:

-

Reaction Process

-

Feature:

-

Laborotary

-

Structure:

-

Lateral Rotation

-

Machine type:

-

Chemical Batch Reactor

-

Agitator:

-

Impeller

-

Reaction Flask:

-

50-200L

YUHUA 500Ml Reactor Biomass Tank Stainless Steel 100L Chemical Reactor High Pressure

Product Description

As chemical industry, chemistry, the rapid development of new drugs and new compounds, greatly improve the efficiency of the chemical to the company to keep pace with The Times, can provide from the simple reaction kettle system needed by the body to the complex process, the product can be with circulating water vacuum pump, diaphragm pump, high and low temperature circulation device, one-stop supporting, for your choice of free development reflect the synthesis Our double-layer Stainless steel reactor supports are made of 304 stainless steel, beautiful and durable.

Characters

1.This product is more advanced, more ideal and practical for our company at home and abroad. The triple elastic design of the support frame ensures the response operation under heavy load, and is compatible with the safety of rising shift.

2.High borosilicate glass (GG17) with excellent physical and chemical properties.

3, can be in the high temperature of 200 ℃ to 120 ℃ low temperature - large temperature range.

4. surface of the support is sprayed with teflon, which is resistant to strong corrosion and can maintain the aesthetics and service life of the whole machine.(spray molding is also available)

5, advanced frequency control, frequency controller, internal components with vacuum coating protection, corrosion resistance, can choose full explosion proof, safe and reliable.

6. There are two layers in the kettle body, in the middle of which heat source and cooling liquid are used to provide the reaction needs.Three layers of kettle body, the first layer for vacuum sandwich kettle body for insulation, the second layer for the reaction to provide heat and cold.Fully transparent reaction bottle can make the reaction process clear at a glance.

7, PTFE components sealed, special design, can maintain the best vacuum degree of similar products in the market (about -0.098mpa), discharge valve can release concentrated liquid and trace solid material, leading in China.

8, jacket pressure control device, for the company's new technology of the kettle body protection, make the work more safe and reliable.

9. The kettle chamber and sandwich sleeve are designed with no dead Angle, anti-corrosion and pollution-free structure.

10. After the reaction, the heat transfer medium can be completely eliminated without hydrops.

11, the product structure science, its beautiful, practical, leading domestic.

12, high-performance PTFE combination seal frequency conversion stirring

Technical Parameters

|

Model

|

50

L

|

100L

|

200L

|

|

Stirring Power

|

90W 1/3

|

90W 1/3

|

120W

/1/3

|

|

Voltage

|

220V/50HZ

|

220V/50HZ

|

220V/50HZ

|

|

Speed

|

0-450 rpm

|

0-450 rpm

|

0-450 rpm

|

Detailed Images

Packing & Delivery

Our Company

FAQ

Q:

What Glass Reactor you supply??

A:

Now we supply standard single layer glass reactor, jacketed glass reactor, triple glass reactor from 1L,2L,3L,5L,10L,20L,30L,50L,100L,200L and customized type as your request,we not only supply instrument but solution provider

Q:

Whats matched device for glass reactor?

A:

1. Vacuum pump

2. Circulating heater

3. Chiller

We can match you circulating heater and chiller, range of temperature from -80 to 300ºC and vacuum pump if you need vacuum reaction condition

Q:

MOQ of Reactors Supply??

A:

1 set can supply

Q:

Delivery Time of Reactor After Place Order??

A:

Generally within 5 working days after payment if in stock, if customized usually 7-10 working days

Q:

Whats Your Warranty Time??

A:

12 months, within warranty time, all parts free changeable only pay freight, after warranty time all parts changeable as produced cost

Hot Searches