- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

Submarine Fiber Optic Cable

-

Outer Sheath:

-

Asphalt sheath

-

Application:

-

Telecommunication

-

Communication application:

-

Underwater

-

Fiber Count:

-

2~144 Cores

-

Fiber type:

-

G652D, G655, G657, Ala(50/125),Alb(62.5/125)

-

Tube:

-

Aluminum tube

-

Armored:

-

Steel armored

-

Inner sheath:

-

PE sheath

Quick Details

-

Brand Name:

-

changguang

-

Model Number:

-

Submarine Fiber Optic Cable

-

Place of Origin:

-

Shanghai, China

-

Product Name:

-

Submarine Fiber Optic Cable

-

Outer Sheath:

-

Asphalt sheath

-

Application:

-

Telecommunication

-

Communication application:

-

Underwater

-

Fiber Count:

-

2~144 Cores

-

Fiber type:

-

G652D, G655, G657, Ala(50/125),Alb(62.5/125)

-

Tube:

-

Aluminum tube

-

Armored:

-

Steel armored

-

Inner sheath:

-

PE sheath

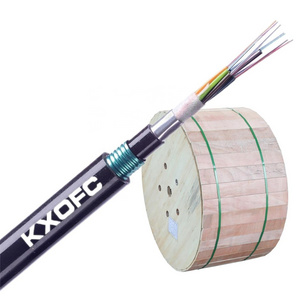

High Quality Communication Use Underwater Direct Buried Submarine Fiber Optic Cable

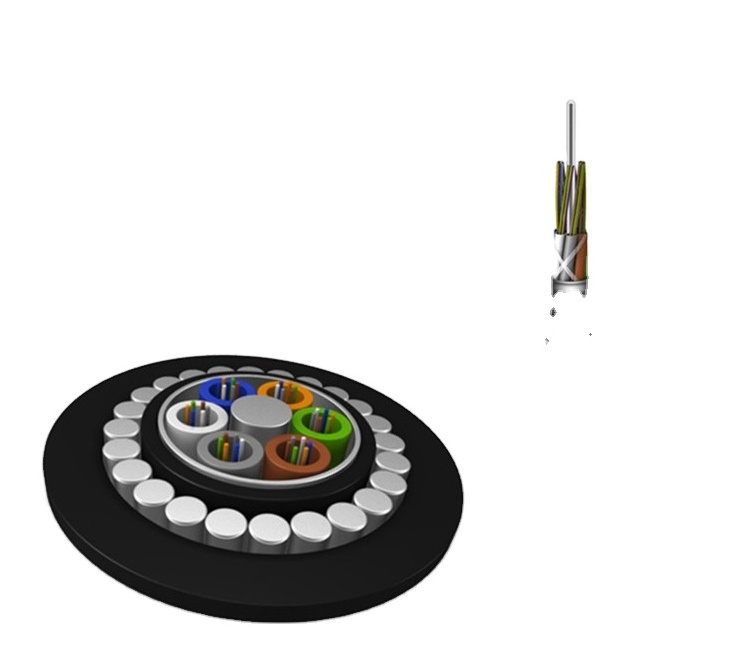

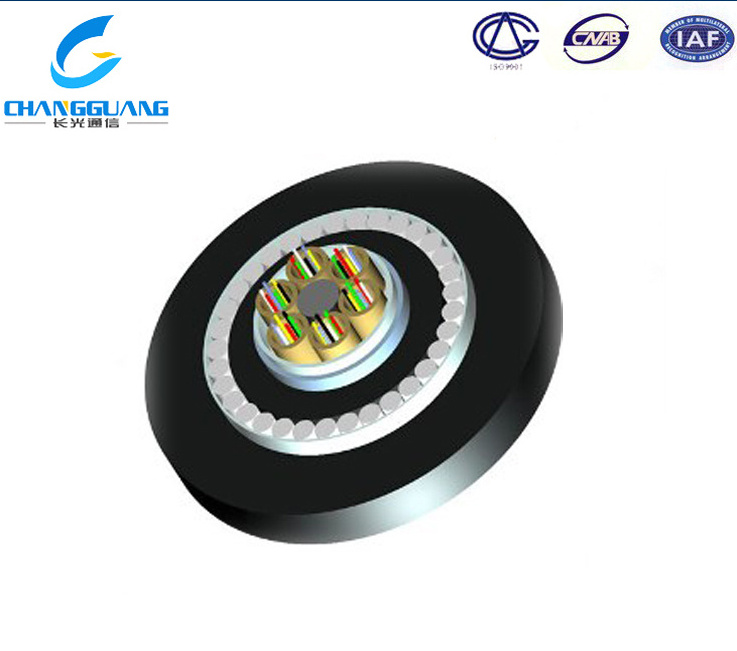

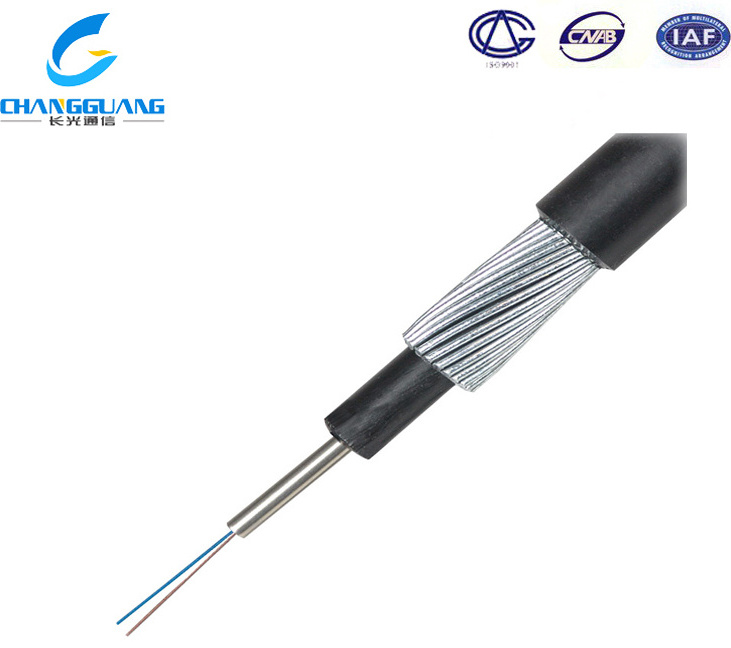

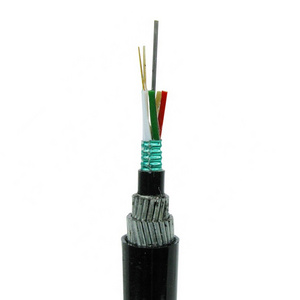

The fibers, either of single-mode or multi-mode type , are placed in a aluminum tube . The tubes are filled with a water-resistant filling compound . A steel wire sometimes sheathed with polyethylene(PE) for cable with hight fiber count,locates in the center of core as a metallic strength member. Tubes(and fillers) are stranded around the strength member into a compact and circular cable core. An Aluminum Polyethylene Laminate(APL) is applied around the cable core,which is filled with the filling compound to protect it from water ingress.Then the cable core is covered with a thin PE inner sheath . After the single-steel armored , the cable is finally completed with an outer sheath.

Characteristics:

1. Accurate fiber excess length ensures good mechanical and temperature performance.

2. Single-steel ensures good performance of tensile strength

3. High strength loose tube that is hydrolysis resistant and special tube filling compound ensure a critical protection of fiber.

4. Specially designed compact structure is good at preventing loose tubes from shrinking

5. Crush resistance and flexibility

6. The following measures are taken to ensure the cable watertight:

7.Steel wire used as the central strength member

8.Loose tube filling compound

9.100% cable core filling

10.APL moisture barrier

11.Water blocking material

Other Picture

Show

:

Technical Parameters:

Submarine Fiber Optic Cable

|

Total number of fiber cores |

2-114 |

|

|

Outer diameter (mm) |

13-24 |

|

|

Cable Max unit weight (kg/km) |

200-450 |

|

|

Allowable pull force (N) |

long-term |

1500 |

|

short-term |

3000 |

|

|

Allowable crush strength (N/100mm) |

long-term |

1500 |

|

short-term |

3000 |

|

|

Min bending radius (mm) |

static |

12.5 times of cable external diameter |

|

dynamic |

25 times of cable external diameter |

|

|

Application of temperature |

-40°C-70°C |

|

Note:

1. Cables can be supplied with a range of single mode or multimode fibers.

2. Specially designed Cable structure is available on request.

Submarine Fiber Optic Cable