- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

9000*1000*1600mm

-

Power (kW):

-

23KW

-

Weight (KG):

-

2500 kg

-

Panel Feed Speed(m/min):

-

28m/min

-

Usage:

-

Furniture Production

-

Application:

-

Flooring Board.MDF Laminate.HDF Laminated

-

Feeding Speed:

-

15-28m/min

-

Panel Length:

-

Min.200mm

-

Panel Width:

-

Min.60

-

Edge Thickness:

-

0.3-3mm

-

Panel Thickness(mm):

-

10-60mm

-

Work Pressure:

-

0.7Mpa

-

Color:

-

Customer's Requirement

-

Machine name:

-

Fully Automatic Edge Banding Machine

-

Gluing:

-

Single

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MISHI

-

Voltage:

-

220V or 380V or option

-

Dimension(L*W*H):

-

9000*1000*1600mm

-

Power (kW):

-

23KW

-

Weight (KG):

-

2500 kg

-

Panel Feed Speed(m/min):

-

28m/min

-

Usage:

-

Furniture Production

-

Application:

-

Flooring Board.MDF Laminate.HDF Laminated

-

Feeding Speed:

-

15-28m/min

-

Panel Length:

-

Min.200mm

-

Panel Width:

-

Min.60

-

Edge Thickness:

-

0.3-3mm

-

Panel Thickness(mm):

-

10-60mm

-

Work Pressure:

-

0.7Mpa

-

Color:

-

Customer's Requirement

-

Machine name:

-

Fully Automatic Edge Banding Machine

-

Gluing:

-

Single

Technical Parameters

|

Model

|

Fully Automatic Edge Banding Machine

|

|

Total power

|

23kw

|

|

Dimensions

|

9000*1000*1600mm

|

|

Feeding speed

|

15-28m/min

|

|

Sheet length

|

≥200mm

|

|

Sheet width

|

≥60mm

|

|

Sheet thickness

|

10-60mm

|

|

Edge banding thickness

|

0.3-3mm

|

|

Workingpressure

|

0.7Mpa

|

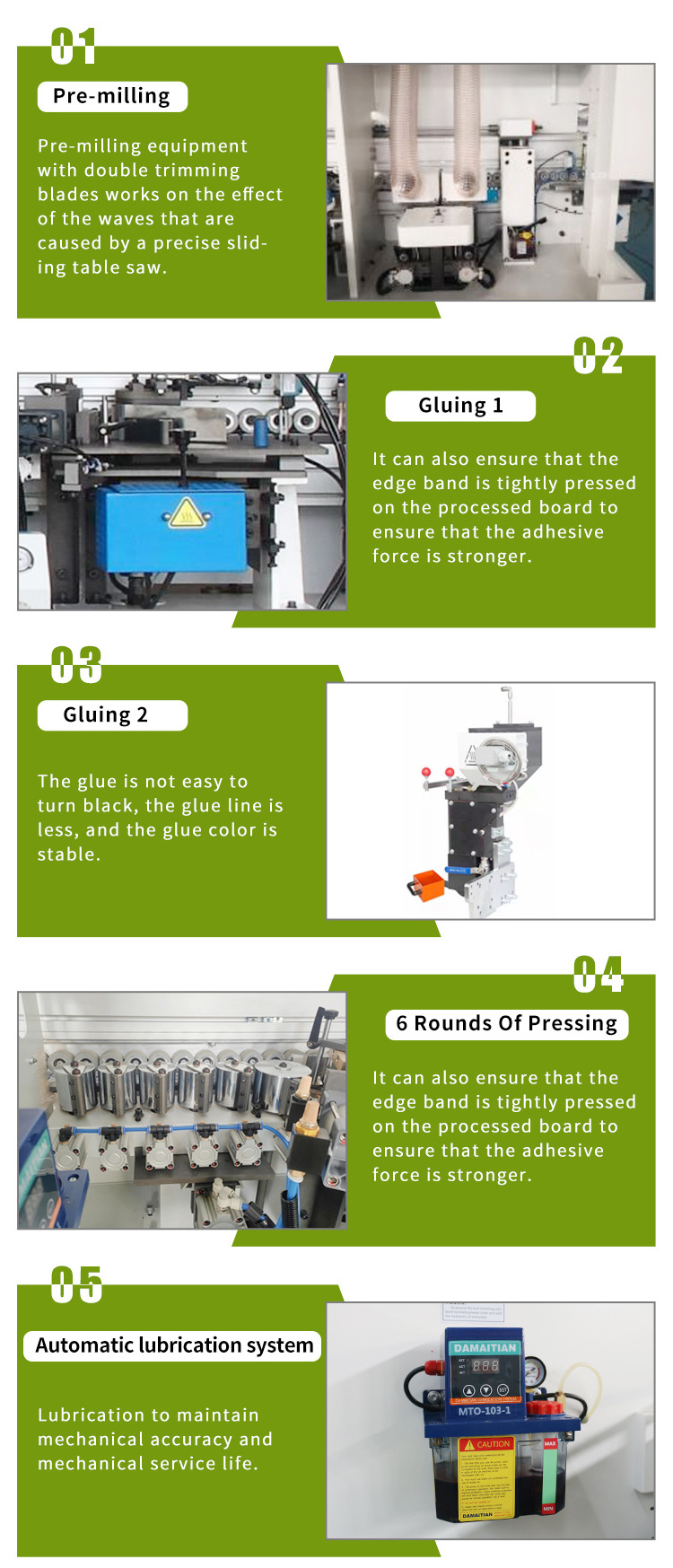

Detailed Images

Product Description

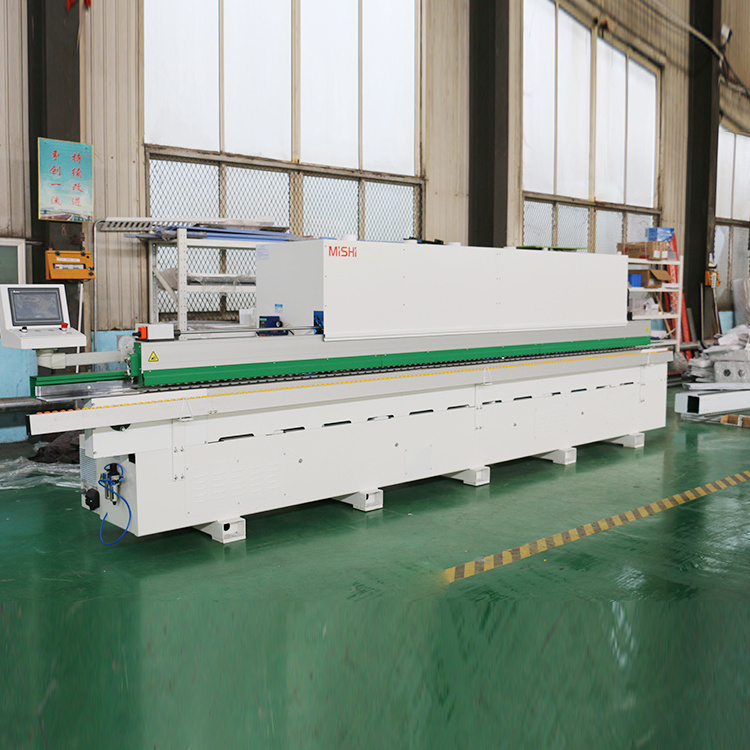

MS-768JX is a fully automatic high-speed edge banding machine with a maximum speed of 28m/min.

This model has complete functions, stable and powerful system, intelligent operation control and high-speed and high-efficiency production, which is suitable for mass production of panel furniture. Using high-quality materials and brand configuration, it can adapt to high and low temperature climates and other harsh environments for production and operation, and has the characteristics of stable production, maintenance-saving, and durability.

This model has complete functions, stable and powerful system, intelligent operation control and high-speed and high-efficiency production, which is suitable for mass production of panel furniture. Using high-quality materials and brand configuration, it can adapt to high and low temperature climates and other harsh environments for production and operation, and has the characteristics of stable production, maintenance-saving, and durability.

Application

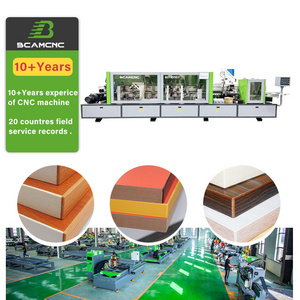

The automatic edge banding machine is used for edge banding processing of MDF, blockboard, solid wood board, particle board, polymer door panel, plywood, etc. It has functions such as flushing, rough repairing, fine repairing, profiling tracking, edge scraping, polishing, etc. The edge sealing effect is fine, smooth, and feels good, and the sealing line is straight and smooth. The equipment is stable, reliable an-d durable, and the price is moderate. It is especially suitable for large and medium-sized furniture factor-ies, cabinets, wardrobes and other panel furniture manufacturers. Its characteristics are automation, high efficiency, high precision and aesthetics, and it has been widely used in domestic panel furniture manu-facturers.

Company Introduction

After sales service

Shipping and Packing

Packaging Details

1. Outside package: Standard export plywood case for CNC Router for advertising.

2. Inner package: Stretch film and plastic film for humidity.

Port

Qingdao/Shanghai/Yiwu/Dalian/Guangzhou/Tianjin/Shenzhen

FAQ

Q: How to install and maintain the machine?

A: Before you use it, we will send the operation tutorial and installation operation video with an English version to you. If you still can not operate, we will provide video guidance online.

Q: What are the machine working environment requirements?

A: The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

Q: How many days do the goods ready to ship?

A: The specific delivery date needs to be communicated with the sales. If we have stock, it can be shipped within five days. If it is not in stock, it will take 15 to 20 days to prepare goods. By the way, Most of the machines are in stock.

Q: What is the mode of transportation of the products?

A: The specific transportation method can be selected according to the needs, like by sea, by air, or by train. Our trade terms are mostly centered on FOB, but we offer EXW, CIF, depending on which is more convenient for you.

Please feel free to send us an inquiry or message to know more about the machine.

We specialize in CNC routers and laser machines for 12 years

The response will be within 1 minute during working time, And within 6 hours during off duty time.

We specialize in CNC routers and laser machines for 12 years

The response will be within 1 minute during working time, And within 6 hours during off duty time.

you haven't found the machine you need, don't hesitate to contact us too.

We will do best to give you the best suggestion.

We can also supply products related to our machines

Hot Searches