- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Huayang

-

Voltage:

-

380v 50hz 3 phase

-

Dimension(L*W*H):

-

2.5*1.3*0.59m

-

Weight:

-

1500 kg

-

Feeding width:

-

914-1450mm, 914-1450 Mm

-

Name:

-

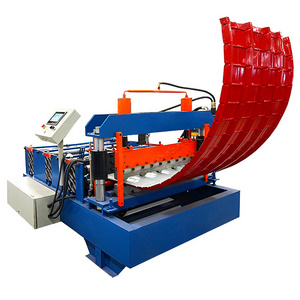

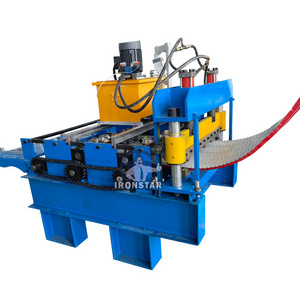

arc curve roof sheet cold roll forming machine

-

Color:

-

Clients' Requirements

-

Control system:

-

PLC(imported Brand)

-

Main motor power:

-

3.3 Kw

-

Roller stations:

-

3 Steps and as you need

-

Usage:

-

Roof Tile Panel

-

Thickness:

-

0.3-0.8mm Thickness

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Free spare parts

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Huayang

-

Voltage:

-

380v 50hz 3 phase

-

Dimension(L*W*H):

-

2.5*1.3*0.59m

-

Weight:

-

1500 kg

-

Feeding width:

-

914-1450mm, 914-1450 Mm

-

Name:

-

arc curve roof sheet cold roll forming machine

-

Color:

-

Clients' Requirements

-

Control system:

-

PLC(imported Brand)

-

Main motor power:

-

3.3 Kw

-

Roller stations:

-

3 Steps and as you need

-

Usage:

-

Roof Tile Panel

-

Thickness:

-

0.3-0.8mm Thickness

-

After Warranty Service:

-

Field maintenance and repair service

-

After-sales Service Provided:

-

Free spare parts

Product Description

|

Feeding material

|

PPGl/aluminum/glgl

|

|

Thickness of the plate

|

0.3--0.8mm

|

|

Diameter of the axle

|

70mm

|

|

Rolling stages

|

3stages

|

|

Productivity

|

8 16m/min

|

|

Total power

|

4kw machine motor + 3kw pump station motor

|

|

Voltage

|

220V 60Hz 3phase or as requirement

|

|

Base frame

|

300H steel

|

|

Side board thickness

|

14mm

|

|

Cutting blade

|

Cr12 with heat treatment

|

|

Cutting system

|

Hydraulic cuting system afer forming

|

|

Control cabinet

|

PLC and frequency changer in it

|

Our curving sheet machine is

customized

, we will design and produce the machine as your

personal requirements

. Different country have different profiles, if you want this machine please just give me your profile.

Product Details

Product Advantages

PRODUCT DISPLAY

Garden-style factories, tourist attractions, pavilions,pavilions, hotels, villas, exhibition halls, resorts, homes and other buildings and outdoor decoration

RELATED PRODUCTS

COMPANY PROFILE

Stud/ track/truss/furring frame roll forming machine, rolling shutter machine, door frame machine, high frequency tube welded forming machine, gutter machine, downpipe machine, floor deck machine and etc. Sticking to the principle of“Quality is our culture”. We can design according to our customers' requirements and we will do our best to meet your needs.

We have professional team to design kinds of roll forming machines according to our customers requirement.We can send our technicians to customer's factory for installation, and teach customer's workers how to use the machines. If there is any problems happened to the machine, we will provide solution at once.Hope we could establish win-win business relations in the soon future!

We treat all customers as friend ,before purchasing ,we guide our customer to choose suit machine .after purchase,we supply effective after-sale service .We still try our best to let all customers satisfied not only our machine quality but also our service .

Customer praise

FAQ

A:- What is your payment term?

- 30% of the total payment should be paid as deposit ,the balanced should be paid after check the finished photos and videos well ,we supply test report.

B:- Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

C:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

D:- What is the after- sale service?

- 24 months from time of loading by seller quality guarantee, life guarantee repair.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the

quality guarantee period, only charge the production cost of the spare parts.Free technical supporting and maintenance consulting in lifetime.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the

quality guarantee period, only charge the production cost of the spare parts.Free technical supporting and maintenance consulting in lifetime.

E:-Can you accept OEM?

- We can accept OEM

- 30% of the total payment should be paid as deposit ,the balanced should be paid after check the finished photos and videos well ,we supply test report.

B:- Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

C:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

D:- What is the after- sale service?

- 24 months from time of loading by seller quality guarantee, life guarantee repair.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the

quality guarantee period, only charge the production cost of the spare parts.Free technical supporting and maintenance consulting in lifetime.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the

quality guarantee period, only charge the production cost of the spare parts.Free technical supporting and maintenance consulting in lifetime.

E:-Can you accept OEM?

- We can accept OEM

Hot Searches