- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

215-684-8

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Keer

-

Model Number:

-

KE-GP

-

Product name:

-

low-melting sealing frits

Quick Details

-

CAS No.:

-

7631-86-9

-

Other Names:

-

low-meiting sealing frits

-

MF:

-

SiO2,CaO,Na2O,TiO2

-

EINECS No.:

-

215-684-8

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Keer

-

Model Number:

-

KE-GP

-

Product name:

-

low-melting sealing frits

Product Description

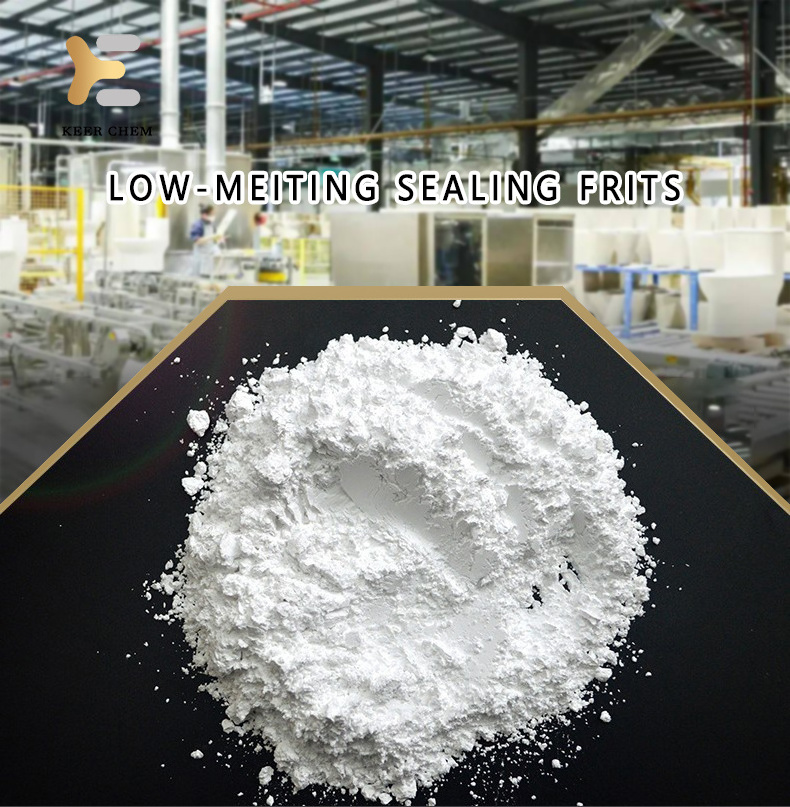

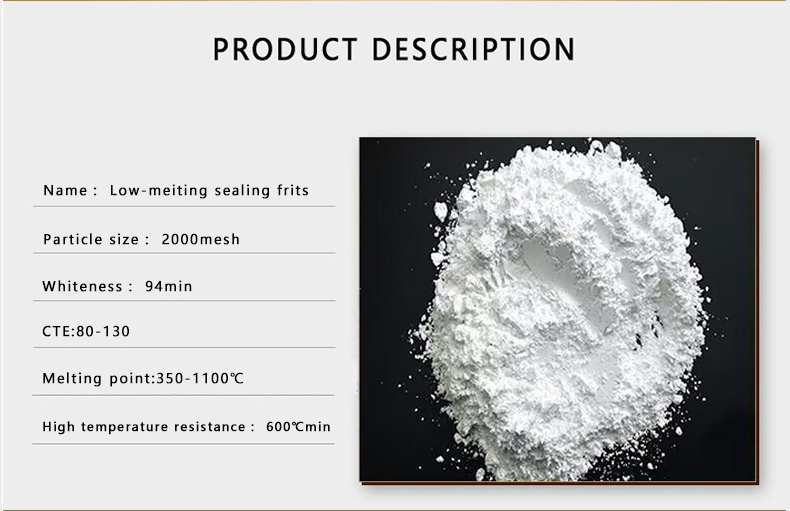

low-melting sealing frits

Low-temperature melting glass powder, namely low-melting glass powder, lead-containing low-melting glass powder (D240), lead-free low-melting glass powder (D250) is different from glass powder, and its production formula is different from glass powder, and its function is superior to glass powder . Low-temperature melting glass powder should be distinguished from glass powder. Low-temperature melting glass powder is made of relatively environmentally friendly materials, which are mixed and melted and co-crystallized in a high-temperature environment to produce silicon and boron metal salts. It has the remarkable characteristics of ultra-low temperature melting (generally 390-1100). ℃). The usual glass powder in the market is organic amorphous hard particles. The raw material is PbO and other heavy metal materials to undergo high-temperature solid-phase reaction to form a glass homogenous body with a disordered structure.

Low melting point glass powder is made of natural high-purity non-metallic minerals: kaolin, limestone, wollastonite, silica, nepheline, potash feldspar, albite, boron salt and environmentally friendly fluxing materials, etc., after crushing, high-purity water treatment, and drying It is a functional micro powder processed by multiple processes such as jet mill and winnowing.

Density: 2.28g/cm3

Mohs hardness: 6.2

Melting point: 390℃ ~1100℃

Manufacturing Technique

|

Type

|

D50(mesh)

|

melt temperature(℃)

|

Density

|

linear expansivity

|

|

D235

|

1500

|

350

|

1.66

|

136*10(-7)

|

|

D240

|

1500

|

400

|

1.87

|

70*10(-7)

|

|

D245

|

1500

|

450

|

1.73

|

90*10(-7)

|

|

D250

|

1500

|

500

|

1.65

|

80*10(-7)

|

|

D255

|

1500

|

550

|

1.67

|

85*10(-7)

|

|

D270

|

1500

|

700

|

1.65

|

90*10(-7)

|

|

D290

|

1500

|

900

|

1.78

|

73*10(-7)

|

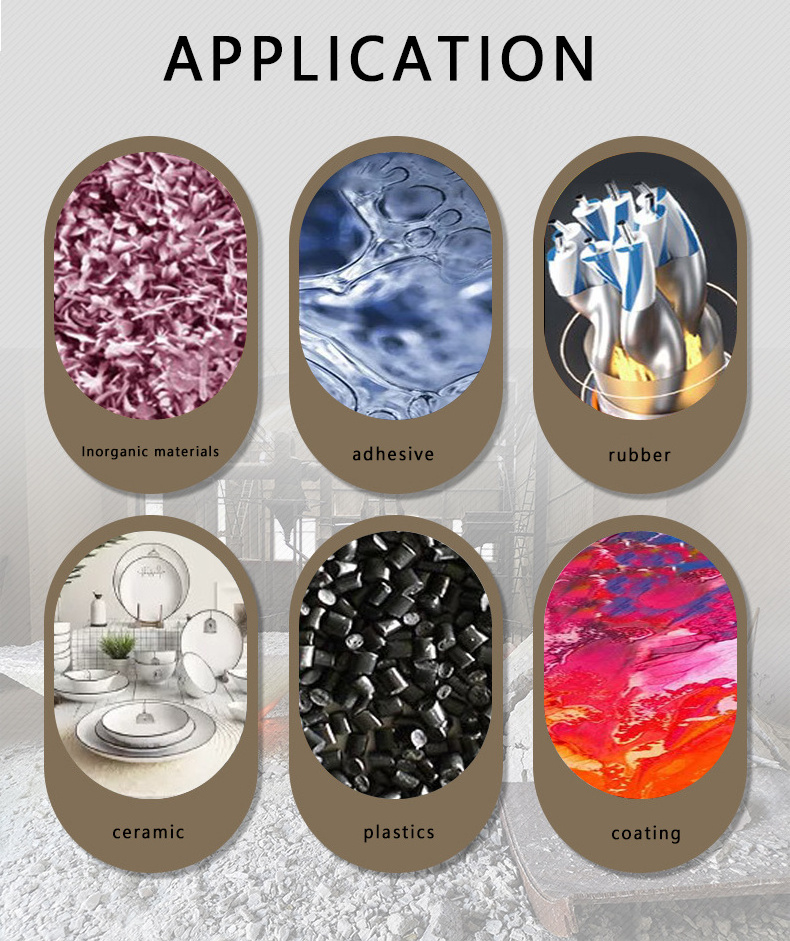

Application

low-meiting sealing frits application:

How to use high-temperature coatings, paints and ink products:

High-temperature coatings, paints and ink products and traditional coatings, paints and ink products, after the painted/painted/printed workpieces are completely pre-treated, there is no major use of processes or methods such as spraying, brushing, roller coating, screen printing and roller printing. Difference; only the curing methods and methods are different. Traditional coatings, paints and inks use room temperature self-crosslinking/reaction curing, heating to 60~180 degrees Celsius curing and AB two-component reaction curing, etc.; and high temperature Coatings, paints and ink products need to absorb enough heat and a certain melting range process to achieve. Usually a tunnel furnace is used, and the process temperature is set at 480 to 700 degrees Celsius to melt and solidify.

The application of low-temperature melting glass powder in high-temperature coatings, paints and ink products should be designed by the laboratory after the small test formula and process test pass. Large-scale production is executed in strict accordance with the established formula and fine-tuning of the process. There are 2 types of water-based system and oil-based system under the design of large formula. Adding method: first add water or solvent, then add low-temperature melting glass powder, pigment, anti-settling agent and a small amount of low-carbon and high-viscosity resin, and disperse at high speed with dispersing equipment. Pro

ducts (if necessary, it is better to use multi-roll equipment or sanding equipment to produce).

Hot Searches