- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7.5kw

-

Weight:

-

1200

-

Dimension(L*W*H):

-

1530x1150x1500mm

-

Name:

-

disc Centrifuge

-

Keyword:

-

salt centrifuge

-

Function:

-

solid and liquid separation machine

-

Material:

-

Stainless Steel 304/316L

-

Operation:

-

Continuous Automatic

-

Discharge:

-

Automaticlly

-

Centrifugal type:

-

disc stack centrifuge

-

Product name:

-

centrifuge separator

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

Wintech

-

Voltage:

-

220/380/Customized

-

Power:

-

7.5kw

-

Weight:

-

1200

-

Dimension(L*W*H):

-

1530x1150x1500mm

-

Name:

-

disc Centrifuge

-

Keyword:

-

salt centrifuge

-

Function:

-

solid and liquid separation machine

-

Material:

-

Stainless Steel 304/316L

-

Operation:

-

Continuous Automatic

-

Discharge:

-

Automaticlly

-

Centrifugal type:

-

disc stack centrifuge

-

Product name:

-

centrifuge separator

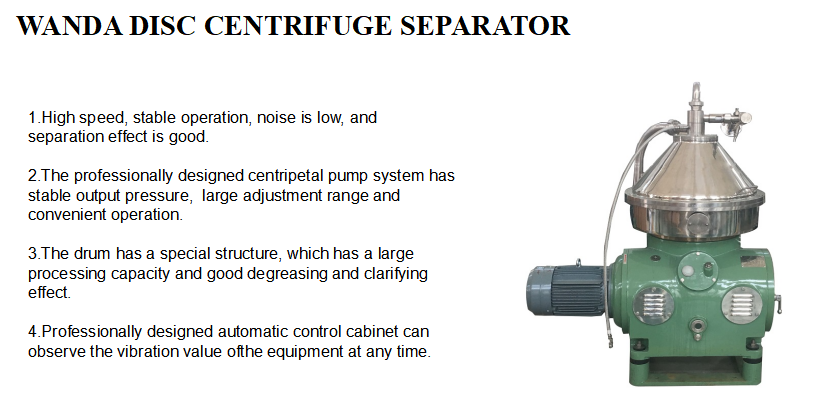

Product Overview

Continuous self cleaning crude oil refinery edible oil extraction disc centrifuge

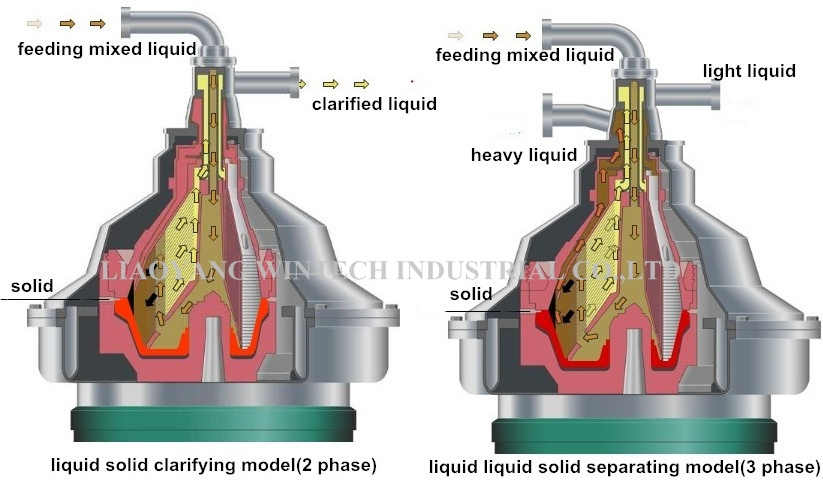

The disc separator is specially used for the two-phase and three- phase separation. The two-phase separation is to separate the suspended solid from liquid or two liquids which have the different specific gravity and are immiscible. The three-phase separation is to separate the two immiscible liquid phases and a phase of solid at the same time.

1. Liquid solid separation (i.e. separation of bottom concentration suspension), which is called clarification operation, that is two-phase separation.

2. Liquid-liquid separation (or liquid-liquid-solid) separation (i.e., the separation of emulsion) is called separation operation,

that is three-phase separation.

Inside the drum is a set of disc-shaped parts, which are nested and folded together. There is a small gap between the discs. The suspension (or emulsion) is added to the drum by the feed pipe at the center of the drum. When the suspension (or emulsion) flows through the gap between the discs, the solid particles (or droplets) settle on the discs under the action of the centrifuge to form sediment (or liquid layer). The sediment slides along the surface of the disc and separates from the disc and accumulates in the place with the largest inner diameter of the drum. The separated liquid is discharged from the outlet of the drum.

The function of the disc is to shorten the settling distance of solid particles (or droplets) and expand the settling area of the drum. The disc installed in the drum greatly improves the production capacity of the separator. The solid accumulated in the drum shall be removed manually after the separator is shut down, or discharged from the drum without shut down through the slag removal mechanism.

Working Principle

The bowl rotates at a high speed around the main axis, driven by a motor through hydraulic coupling and screw gear pair. Liquid flows from the upper feeding pipe into the bowl's bottom and then will be separated through holes of disc seat. With the action of centrifugal force , heavy liquid flows along the inner wall of discs to the inner wall of the bowl, then it will be discharged by the heavy liquid pump, the light liquid will be discharged by the light liquid pump, which flows along the inner wall of discs into center pipe and then up to high liquid outlet,the larger solid phase particles left will sediment on the bowl's wall and then will be discharged by the sliding bowl through the sediment outlet.

PRODUCT SPECIFICATIONS

|

Mode

|

Treatment Capacity (L/H)

|

Inlet Pressure (Mpa)

|

Outlet Pressure (Map)

|

Motor Power (KM)

|

Weight (kg)

|

Outline Dimension (mm)

|

|

DHNY400

|

2000-5000

|

0.05

|

0.3

|

7.5

|

1500

|

1600*1300*1600

|

|

DHNY500

|

5000-10000

|

0.05

|

0.4

|

15

|

1800

|

1800*1300*1800

|

|

DHNY550

|

10000-20000

|

0.05

|

0.4

|

22

|

2500

|

2050*1600*2050

|

|

DHNY700

|

25000-35000

|

0.05

|

0.3

|

37

|

3000

|

2200*1800*2000

|

|

DHNZ204

|

1000-1500

|

0.05

|

0.2

|

4

|

600

|

900*850*1400

|

|

DHNZ400

|

1000-3000

|

0.05

|

0.3

|

7.5

|

1500

|

1600*1300*1600

|

|

DHNZ500

|

3000-7000

|

0.05

|

0.4

|

15

|

1850

|

1800*1300*2030

|

|

DHNZ550

|

5000-10000

|

0.05

|

0.4

|

22

|

2550

|

2050*1300*1600

|

|

DHY400

|

1200-3000

|

0.05

|

0.3

|

7.5

|

1500

|

1600*1300*1600

|

|

DHY500

|

2500-8000

|

0.05

|

0.4

|

15

|

1800

|

1800*1300*1800

|

|

DHY550

|

6000-15000

|

0.05

|

0.4

|

22

|

2500

|

2050*1600*2050

|

|

DHY700

|

15000-35000

|

0.05

|

0.3

|

37

|

3000

|

2200*1800*2000

|

|

If you are not sure which model is suitable for you, feel free to contact us!

|

Product More Pictures

Machine use site

Our disc centrifuge is working well with the customer, use one set individually or multi sets together are all good choices.

Hot Searches