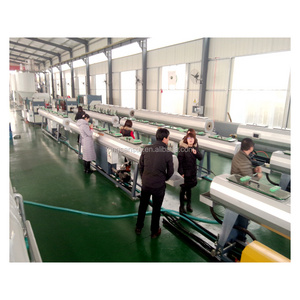

2. The PE sizing and cooling system adopts water film lubrication and water ring cooling to meet the requirements of HDPE materials and ensure the stability of diameter and roundness during high-speed production of wall pipes.

3. The specially designed multi-stage vacuum calibrating box to control the vacuum degree ensures the dimensional stability and roundness of HDPE pipes.

4. The extruder and haul-off machine are driven and controlled by imported speed governors, with good stability, high precision and high reliability.

5. The running time of the entire PE pipe production line equipment is controlled by PLC program, with a good human-machine interface, and all process parameters can be set and displayed through the touch screen.

6. It can be equipped with a marking line extruder to produce pipes with color marking lines that meet the requirements of national standards.