- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HYB

-

Dimension(L*W*H):

-

Different model is difference.

-

Weight:

-

6500 KG

-

Marketing Type:

-

New Product 2024

-

Product Name:

-

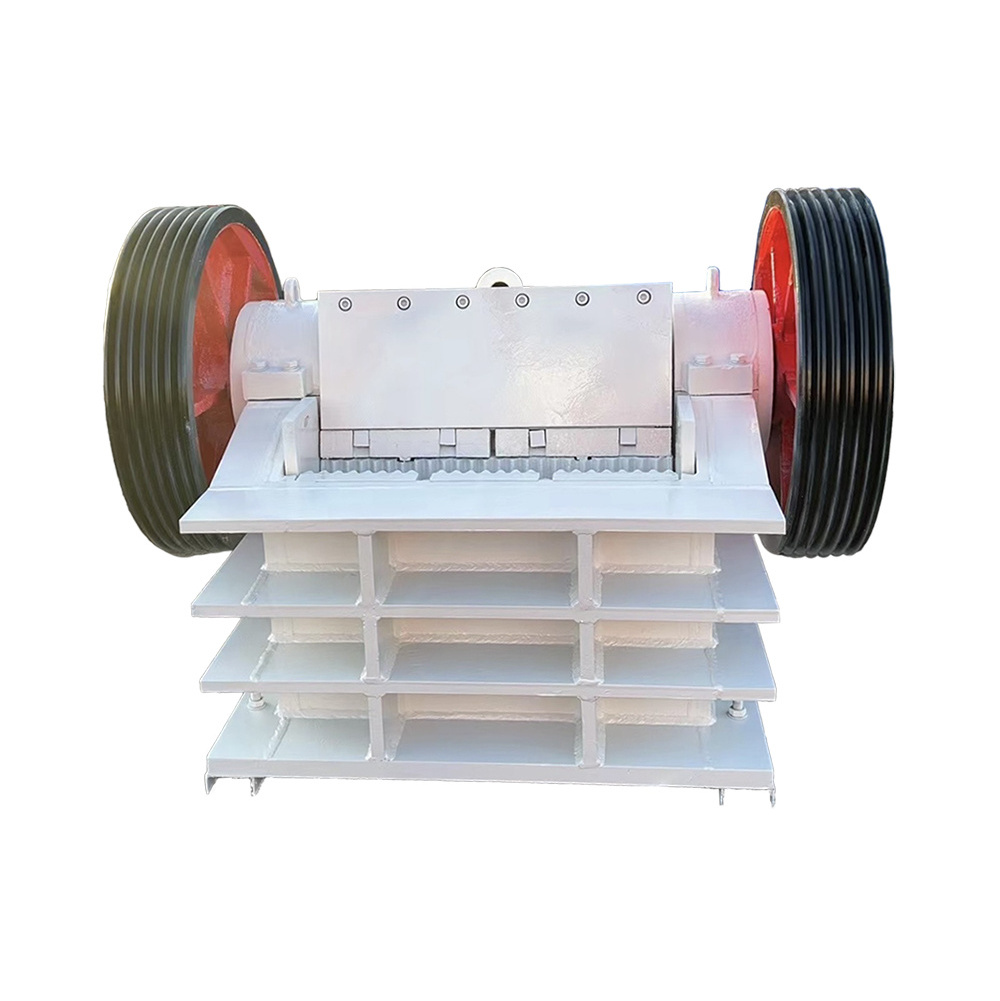

Jaw Crusher

-

Spare Parts Supply:

-

Support

-

Supplier Type:

-

Manufacturer

-

Certificate:

-

ISO9001

-

After-sale Service:

-

Support

-

Keyword:

-

PE jaw crusher,PEX jaw crusher,C series jaw crusher

-

Applicaton Fields:

-

Metallurgy, mining, chemical, cement, construction, etc.,.

-

Applicaton Material:

-

Limestone, dolomite, phosphate ore.

-

Discount Apply:

-

Support

-

Factory Visit:

-

Warmly Welcomed

Quick Details

-

Application:

-

Mining Used

-

Capacity(t/h):

-

8~1275

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

HYB

-

Dimension(L*W*H):

-

Different model is difference.

-

Weight:

-

6500 KG

-

Marketing Type:

-

New Product 2024

-

Product Name:

-

Jaw Crusher

-

Spare Parts Supply:

-

Support

-

Supplier Type:

-

Manufacturer

-

Certificate:

-

ISO9001

-

After-sale Service:

-

Support

-

Keyword:

-

PE jaw crusher,PEX jaw crusher,C series jaw crusher

-

Applicaton Fields:

-

Metallurgy, mining, chemical, cement, construction, etc.,.

-

Applicaton Material:

-

Limestone, dolomite, phosphate ore.

-

Discount Apply:

-

Support

-

Factory Visit:

-

Warmly Welcomed

Product Description

PE Series Jaw Crusher

is mainly used in the initial crushing position of the sand and gravel production plant, especially for crushing large rocks. Because of its stable operation, large crushing ratio and low operating cost, it can be seen in many sand and gravel crushing, sand making and other sites.

The coarse jaw crusher is the PE series of jaw crushers. The commonly used models are PE400×600, PE500×750, PE600X900, PE750X1060 etc., and the hourly production capacity can reach 1200 tons. The fine jaw crusher is mostly used for the secondary crushing of stone crusher plant. Because the price is relatively cheap, many people use it instead of impact crusher or cone crusher. The commonly models of PEX series jaw crusher are PEX150×750, PEX250×1000, PEX300×1300, etc. The output range is about 8-100 tons per hour.

MC Series Jaw Crushers with high throughput, low energy consumption, reliable structure and easy maintenance,being the preferred primary crushers for various rocks.

The coarse jaw crusher is the PE series of jaw crushers. The commonly used models are PE400×600, PE500×750, PE600X900, PE750X1060 etc., and the hourly production capacity can reach 1200 tons. The fine jaw crusher is mostly used for the secondary crushing of stone crusher plant. Because the price is relatively cheap, many people use it instead of impact crusher or cone crusher. The commonly models of PEX series jaw crusher are PEX150×750, PEX250×1000, PEX300×1300, etc. The output range is about 8-100 tons per hour.

MC Series Jaw Crushers with high throughput, low energy consumption, reliable structure and easy maintenance,being the preferred primary crushers for various rocks.

|

Application Fields

|

|

Metallurgy, mining, chemical, cement, construction, etc.,.

|

|

|

|||

|

Applied Materials

|

|

Limestone, dolomite, phosphate ore.

|

|

|

|||

Specification

Jaw Crusher Parameter:

PE Series Jaw Crusher

is developed and applied widely in mines,quarries,road construction ,on the base of domestic and abroad advanced technology.

The jaw crusher is with large crushing rate and high productivity,could crush the material up to 300MPA.

MC Series Jaw Crusher

are all made by the new modular,no welded frame structure,thus gives the equipment maximum fatigue resistance,the best reliability and a variety of installation methods.The combination of high quality cast steel components and first-class ball rolling bearings fully ensures high yield,high efficiency and low cost of crushing operations.

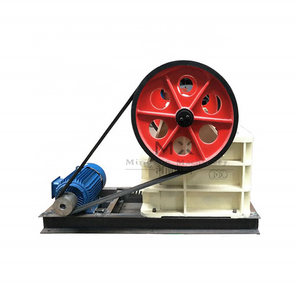

The motor transmits power through belt,drives the moving jaw do periodic motion to the fixed jaw surround the eccentric shaft.

The angle between toggle plate and moving jaw increases when moving jaw moves up. So the moving jaw closes to the fixed jaw,and the stuff will be crushed in multiple ways.The angle of jaw crusher between toggle plate and moving jaw decreases when moving jaw moves down,the moving jaw of jaw crushers moves away from fixed jaw by the pulling force of rod and spring,the products after crushing will be discharged from the outlet of jaw crusher.

Working Principle And Parts Applications:

Working Principle:

When Symons cone crusher works, the motor drives the eccentric sleeve rotating through the V-belt, the large pulley, the transmission shaft, the bevel gear, and the large bevel gear. The conical shaft core rotates and moves by the driving of the eccentric sleeve, causing the surface of the broken wall to be close or leave the surface of the rolling wall, therefore, the material is continuously crushed by the crushing and bending in the annular crushing cavity composed of the fixed cone and the moving cone. After multiple extrusion impacts and bending, the material is crushed to the required particle size and discharged through the lower portion.

Packing & Delivery

Hot Searches