1.It has been installed with the KAF gear reducer and electrical control box.key components are made of high quality alloy steel adds wear-resisting material, Using heat treatment;Service life can be extended 5-7 times.

2.High output, low consumption and noise, better stability and lower fault rates, improved fatigue resistance, continuous production, economy and durability.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LEABON

-

Voltage:

-

50HZ

-

Dimension(L*W*H):

-

1.2*0.6*1.1

-

Motor Power (Kw):

-

22kw Machine Pellet

-

Power (kW):

-

22kw Pellet Press

-

Weight (KG):

-

550 KG

-

Name:

-

homemade wood pellet machine

-

Feature:

-

home using

-

Keywords:

-

homemade wood pellet machine

-

Dimension(m):

-

1.2*0.6*1.1

-

Application:

-

Homemade Wood Pellet Machine

-

Color:

-

Customers' Requirements

-

Spare parts:

-

Flat Die+ Rollers

-

Service:

-

24 Hours Online

-

Certification:

-

CE Pellet Press

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

250 - 300 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LEABON

-

Voltage:

-

50HZ

-

Dimension(L*W*H):

-

1.2*0.6*1.1

-

Motor Power (Kw):

-

22kw Machine Pellet

-

Power (kW):

-

22kw Pellet Press

-

Weight (KG):

-

550 KG

-

Name:

-

homemade wood pellet machine

-

Feature:

-

home using

-

Keywords:

-

homemade wood pellet machine

-

Dimension(m):

-

1.2*0.6*1.1

-

Application:

-

Homemade Wood Pellet Machine

-

Color:

-

Customers' Requirements

-

Spare parts:

-

Flat Die+ Rollers

-

Service:

-

24 Hours Online

-

Certification:

-

CE Pellet Press

Malaysia Pellet Machine Wood Sawdust Pelletizer Homemade Pellet Mill Pricing

Products description

Introduction

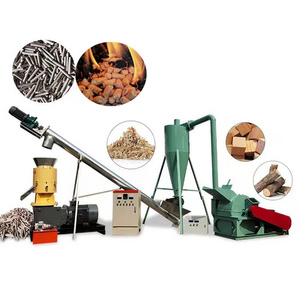

1.Leabon wood pellet machine is suitable for making biomass particles such as sawdust,rice husk,paddy straw,sunflower

stalk.hulls,forestry wastes,pellet ,etc.

2.Use Cold-pressing molding technology, the raw material is under dried,condition,which is compressed,and formed into small eraser-sized bits, the final pellets is clean,pleasant and smooth:its density is more than 1.0g/cm3.

1.Leabon wood pellet machine is suitable for making biomass particles such as sawdust,rice husk,paddy straw,sunflower

stalk.hulls,forestry wastes,pellet ,etc.

2.Use Cold-pressing molding technology, the raw material is under dried,condition,which is compressed,and formed into small eraser-sized bits, the final pellets is clean,pleasant and smooth:its density is more than 1.0g/cm3.

Leabon Machinery has different types Flat Die Wood Pellet Machine

1.Flat Die Wood Pellet Machine(Elecrtic Motor)

|

Model

|

Capacity(kg/h)

|

Motor(KW)

|

Pellet Size(mm)

|

Dimension(m)

|

Weight(kg)

|

|

KAF-250

|

150-200

|

15

|

6,8

|

1.1* 0.55* 0.95

|

400

|

|

KAF-300

|

250-300

|

22

|

6,8,10

|

1.2* 0.6* 1.1

|

550

|

|

KAF-350

|

300-400

|

30

|

6,8,10

|

1.45*0.8*1.3

|

850

|

|

KAF-450

|

450-600

|

45

|

6,8,10,12

|

1.5* 0.85* 1.55

|

1300

|

|

KAF-550

|

700-800

|

55

|

6,8,10,12

|

1.55*0.9*1.65

|

1600

|

2.Flat Die Wood Pellet Machine(Tractor-Driven/PTO)

Home Tractor Driven Flat Die Straw Pellet Make Machine in Wood Pellet Mill for sale is mainly applied to granulation such as sawdust, rice husk, cotton stalk, cotton seed skins, weeds and crop stalks and other plant wastes can also be applied to fertilizer,

organic manure, fertilizer and fuel pellet.

|

Model

|

Output (kg/h)

|

Pellet (mm)

|

Mould (mm)

|

Size (mm)

|

Weight (kg)

|

|

PM-200T

|

100-120

|

6,8

|

200

|

500*450*900

|

150

|

|

PM-250T

|

200-250

|

6,8

|

250

|

550*500*1050

|

280

|

|

PM-300T

|

250-300

|

6,8,10

|

300

|

600*550*1200

|

350

|

|

PM-350T

|

300-500

|

6,8,10

|

350

|

650*600*1300

|

500

|

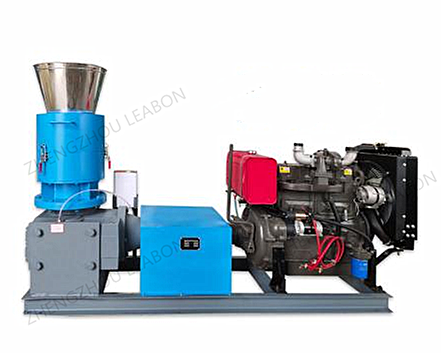

3.Flat Die Wood Pellet Machine(Diesel Engine Driven)

(2) The raw material could be wood sawdust, rice husk, bamboo power, straw, clover, cotton seed shell etc. and can be mixed with all kinds of power materials.

|

Model

|

Output(kg)

|

Power(hp)

|

Flat die diameter

(mm)

|

Pellet(mm)

|

Packing size(mm)

|

Weight(kg)

|

|

200D

|

100-120

|

15

|

200

|

6,8

|

1250*650*1200

|

450

|

|

250D

|

150-200

|

22

|

250

|

6,8

|

1300*700*1300

|

650

|

|

300D

|

250-350

|

32

|

300

|

6,8,10

|

1650*750*1400

|

800

|

|

350D

|

300-500

|

42

|

450

|

6,8,10

|

1350*1100*1100

|

950

|

|

Model

|

Main Power

(kw) |

Capacity

(t/h) |

Feeding Power

(kw) |

Conditioner Power (kw)

|

Die Diameter (mm)

|

Pellet size

(mm) |

|

LH- 320

|

37

|

0.2-0.3

|

1.5

|

2.2

|

320

|

6,8,10,12

|

|

LH- 350

|

55

|

0.5-0.7

|

1.5

|

3

|

350

|

6,8,10,12

|

|

LH- 420

|

90

|

0.8-1

|

2.2

|

5.5

|

420

|

6,8,10,12

|

|

LH- 480

|

90

|

1-1.2

|

2.2

|

5.5

|

480

|

6,8,10,12

|

|

LH- 508

|

132

|

1.5-2

|

2.2

|

5.5

|

508

|

6,8,10,12

|

|

LH- 558

|

160

|

2-2.5

|

2.2

|

5.5

|

572

|

6,8,10,12

|

|

LH- 678

|

185

|

2.5-3.5

|

3

|

11

|

678

|

6,8,10,12

|

|

LH- 768

|

250

|

4-5.5

|

4

|

18.5

|

768

|

6,8,10,12

|

Raw material&Final Products

Application

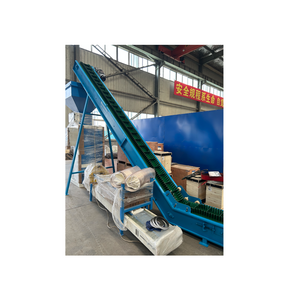

Complete Wood Pellet Production Line

Project Case - Complete Biomass Wood Pellet Production Line

Packing & Delivery

Company

FAQ

(1). What capacity would your need?

-----The Capacity Range of Wood Pellet Machine: 0.5T/H; 0.8-1T/H; 1.5-2T/H; 2-3T;3-4T/H.

(2).What is your raw material?

-----suitable for different raw material such as wood/logs, sawdust, straw,wood chips,nuts shell,waste wood etc.

(3).What is your raw material size?

----Best size for pressing high quality pellets is 3mm-5mm.

(4).What is the moisture of your raw material?

----Better to be 10-15%.( If large than this, then we will recommend your Dryer Machine)

(5).Final Pellets Size?

----We have Diameter for Pellets:6mm, 8mm, 10mm, 12mm, (Different Diameters for your Different Requirement.)

-----The Capacity Range of Wood Pellet Machine: 0.5T/H; 0.8-1T/H; 1.5-2T/H; 2-3T;3-4T/H.

(2).What is your raw material?

-----suitable for different raw material such as wood/logs, sawdust, straw,wood chips,nuts shell,waste wood etc.

(3).What is your raw material size?

----Best size for pressing high quality pellets is 3mm-5mm.

(4).What is the moisture of your raw material?

----Better to be 10-15%.( If large than this, then we will recommend your Dryer Machine)

(5).Final Pellets Size?

----We have Diameter for Pellets:6mm, 8mm, 10mm, 12mm, (Different Diameters for your Different Requirement.)

Contact Rita

Hot Searches