- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

300mm*300mm

-

Cutting Thickness:

-

Depends

-

Control Software:

-

cypcut

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

skyphoenix

-

Weight (KG):

-

650 KG

-

Product name:

-

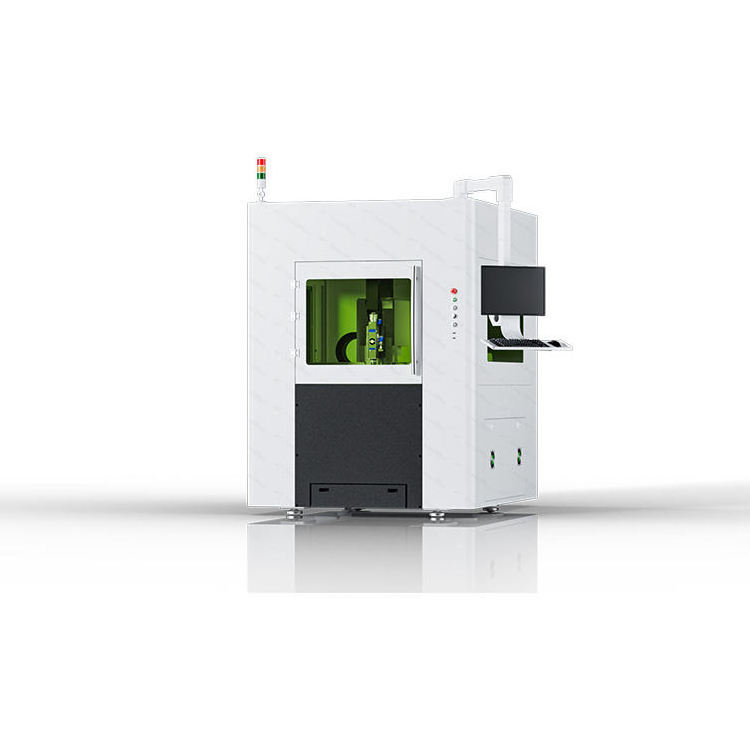

Fiber Laser Cutting Machine

-

Laser power:

-

1000W /1500W/ 2000W

-

Cutting materials:

-

Stainless Steel Carbon Steel Aluminum

-

Laser head:

-

Raytools Cutting Head

-

Working area:

-

300*300mm

-

Control system:

-

Cypcut System

-

Fiber Laser Source:

-

Wuhan Raycus

-

After-sales Service Provided:

-

Online Video Technical Support

-

Transmission system:

-

Precision dual gear rack transmission

-

Assisting gas:

-

oxygen, nitrogen, compressed air

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

0-40000mm/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

300mm*300mm

-

Cutting Thickness:

-

Depends

-

Control Software:

-

cypcut

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

skyphoenix

-

Weight (KG):

-

650 KG

-

Product name:

-

Fiber Laser Cutting Machine

-

Laser power:

-

1000W /1500W/ 2000W

-

Cutting materials:

-

Stainless Steel Carbon Steel Aluminum

-

Laser head:

-

Raytools Cutting Head

-

Working area:

-

300*300mm

-

Control system:

-

Cypcut System

-

Fiber Laser Source:

-

Wuhan Raycus

-

After-sales Service Provided:

-

Online Video Technical Support

-

Transmission system:

-

Precision dual gear rack transmission

-

Assisting gas:

-

oxygen, nitrogen, compressed air

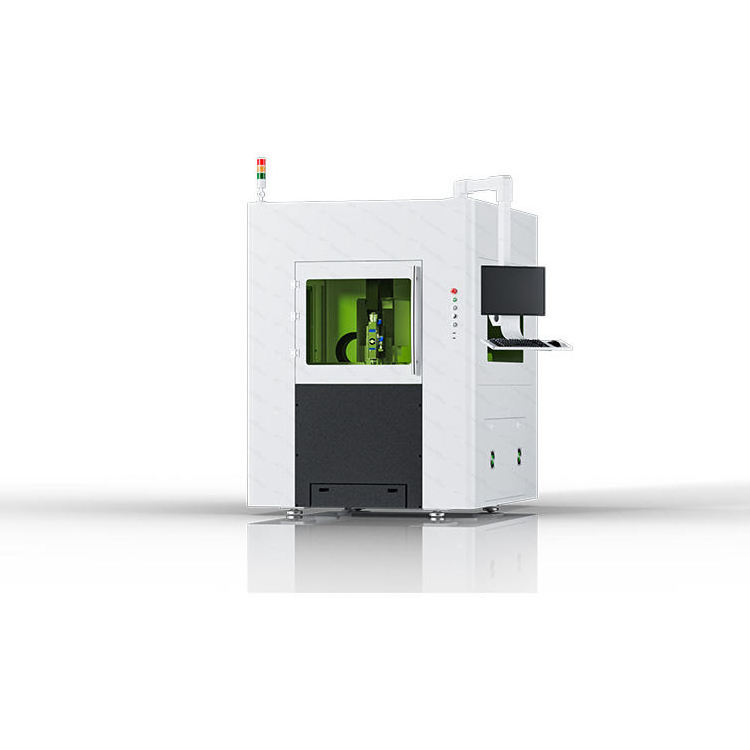

PRODUCT DESCRIPTION

|

Model

|

SP-3030 Fiber laser cutting machine

|

|

Laser type

|

Fiber laser, 1080nm

|

|

Laser power

|

1000W / 1500W / 2000W

|

|

3Working area

|

300mm x 300mm

|

|

Min Line width

|

0.1mm

|

|

Positioning accuracy

|

0.01mm

|

|

Max. Cutting speed

|

60m/min

|

|

Transmission type

|

Precision dual gear rack transmission

|

|

Driving system

|

Serve motors

|

|

Cutting thickness

|

Depending on laser power and material

|

|

Assisting gas

|

Compressed air, oxygen and nitrogen

|

|

Cooling mode

|

Industrial circulation water chiller

|

|

Visual positioning

|

Red dot

|

|

Machine weight

|

Net 650kgs

|

|

Working voltage

|

380V 3 phase

|

DETAILED CONFIGURATION

Product introduce:

1. Ball screw transmission way, improve metal cutting precision.2. Excellent Path Quality: Smaller laser dot and high work efficiency, high quality.

3. High Cutting Speed: cutting speed is 2-3 times than same power laser cutting machine.

4. Stable Running: adopt top world fiber lasers generator, stable performance, key parts can reach 100,000 hours.

5. High Efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

6. Low Cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

7. Low Maintenance: fiber line transmission no need reflect lens, save maintenance cost;

8. Easy Operations: fiber line transmission, no adjustment of optical path.

Ball Screw Transmission

Grinding Precision Screw Transmission, improve machine precision perforamnce.

Laser Cutting Head

Optimized optical configuration and smooth and efficient airflow design.

1500w Fiber Laser Generator

Raycus laser generator, 1000w, 1500w, 2000w, 3000w.etc, optional.

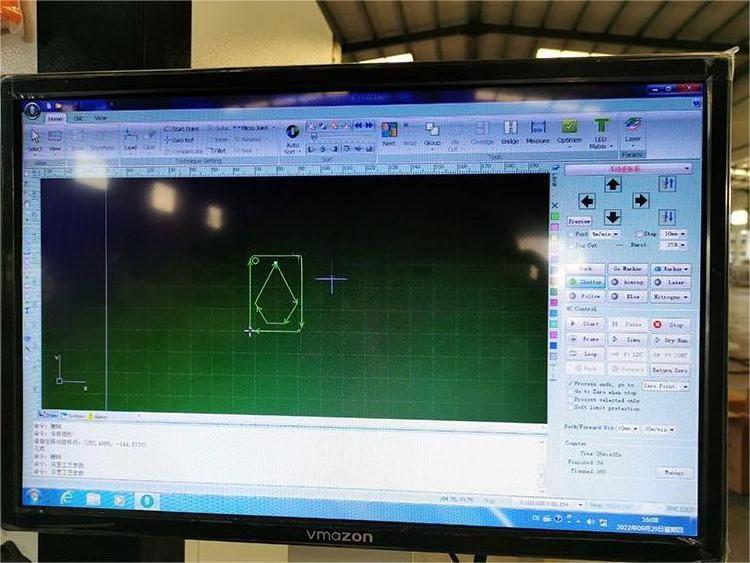

Cypcut Controller

A set of reasonable laser cutting solutions cut from the medium power laser cutting system.

Servo driver and motor

Adjustment-free function, realize instant-on-use, automatic tuning function, improve performance.

S&A Water Chiller

It adopts dual temperature dual control mode and can switch to intelligent temperature control mode.

Control system-cypcut

1. Have flying cutting function.

2. Support AI, BMP, DST, DWG, DXF, DXP, LAS, PLT,NC,GBX etc...

2. Support AI, BMP, DST, DWG, DXF, DXP, LAS, PLT,NC,GBX etc...

Pneumatic Components - Japan SMC

Can easily adjust the air pressure ratio

Precision screw drive and guide rail

Single side double guide rail; High precisionand durable , long life, can provide rigorous support for quenching helical gears and grinding helical gears, so that the load drive structure is compact, can effectively reduce the driving torque.

Automatic Rail Lubrication System

The frequency of use can be set by adjusting the parameters through the computer.

CUTTING PARAMETER

APPLICATIONS

Application industries:

Used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, grain

machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household

appliance, craft giftsm tool processing, decoration, advertising, metal processing, kitchen processing and other manufacturing and processing industries.

Application materials:

Stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, pickled

sheet, copper, silver, gold, titanium and other metal sheet and pipe cutting.

CUSTOMER FEEDBACK

Our products enjoy a high reputation internationally, contact me for samples and discounts

PACKAGE AND DELIVERY

EXHBITION SHOWS

COMPANY PFOFILE

Certificate

CONTACT US

FAQ

1.Q: Why should we choose you ?

A:If you choose us, you will get top quality,best service,reasonable price and reliable warranty.

2.Q: I'm not familiar with the machine,how to choose?

A:Just tell us materials, thickness and working size, I will recommend the suitable machine.

3.Q: How to operate the machine?

A:We will deliver English manual and video with the machine to you.If you still need our further help,please contact us.

4.Q: Can I get the sample to check quality of machine ?

A:Of course.Please provide your logo or design to us, free samples can be provided for you.

5.Q: Can the machine be customized according my requirements?

A:Sure,we have a strong technical team and have rich experience. Our goal is to make you satisfied.

6.Q: Can you arrange the shipment for us?

A:Of course.We can arrange the shipment for our clients accordingly by sea and air. Trading terms FOB, CIF, CFR are available.

A:If you choose us, you will get top quality,best service,reasonable price and reliable warranty.

2.Q: I'm not familiar with the machine,how to choose?

A:Just tell us materials, thickness and working size, I will recommend the suitable machine.

3.Q: How to operate the machine?

A:We will deliver English manual and video with the machine to you.If you still need our further help,please contact us.

4.Q: Can I get the sample to check quality of machine ?

A:Of course.Please provide your logo or design to us, free samples can be provided for you.

5.Q: Can the machine be customized according my requirements?

A:Sure,we have a strong technical team and have rich experience. Our goal is to make you satisfied.

6.Q: Can you arrange the shipment for us?

A:Of course.We can arrange the shipment for our clients accordingly by sea and air. Trading terms FOB, CIF, CFR are available.

Hot Searches