- Product Details

- {{item.text}}

Quick Details

-

Principle:

-

Magnetic Method

-

Range:

-

0-1250um

-

Accuracy error:

-

zero calibration ± (1 + 3% H)

-

Temperature:

-

0-40 ℃

-

Humidity:

-

≤85%

-

Minimum curvature:

-

5mm convex; 5mm concave

-

Thinnest substrate:

-

0.4mm

-

Minimum substrate:

-

10 * 10mm

-

Unit:

-

Um/mil

-

Size:

-

110mm * 65mm * 30mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

A&E LAB

-

Model Number:

-

TG001

-

Principle:

-

Magnetic Method

-

Range:

-

0-1250um

-

Accuracy error:

-

zero calibration ± (1 + 3% H)

-

Temperature:

-

0-40 ℃

-

Humidity:

-

≤85%

-

Minimum curvature:

-

5mm convex; 5mm concave

-

Thinnest substrate:

-

0.4mm

-

Minimum substrate:

-

10 * 10mm

-

Unit:

-

Um/mil

-

Size:

-

110mm * 65mm * 30mm

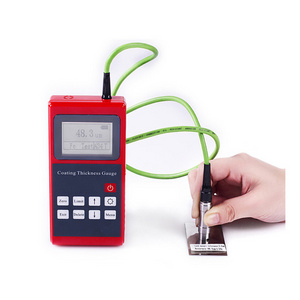

Hot Sale Paint Coating Thickness Gauge

A & E Lab hot selling are including: UV VIS Spectrophotometer, Visible Spectrophotometer, Flame Photometer, PCR-Cycler, Centrifuge, Hotplate, Stirrer, Stirrer Hotplate, Rotory Mixer, 3D Rocker, See-Saw Rocker, Mixer, Orbital Shaker, Melting Point Device, Cold Keeper, Shaker Incubator, Viscometer, Microscope ect.

Hot Sale Paint Coating Thickness Gauge

Introduction of Paint Coating Thickness Gauge

This device is a portable meter. It is capable of measuring coating thickness quickly, precisely and without injury, both for the laboratory and engineering environment. It is currently widely used in manufacturing, metal processing industry, chemical industry, commodity inspection and testing fields, and is essential for material protection major.

This device meets the following criteria:

GB/T 4956-1985 non-magnetic coating thickness measurement on magnetic metal substrate, Magnetic Method

GB/T 4957

-

1985 non-conductive coating thickness measurement on non-magnetic metal substrate, Eddy Current Method

JB/T 8393-1996 Magnetic & Eddy Current coating thickness measurement

Feature of Paint Coating Thickness Gauge

Thickness measurement using both Magnetic Method to measure the non-magnetic coating on a magnetic metal substrate and Eddy Current Method to measure the non-conductive coating on a non-magnetic metal substrate.

Single-point or two-point method could be used to correct probe system deviation, in order to ensure the accuracy of the device in the process of measuring.

Automatic identify ferrous and non-ferrous substrate quickly.

Power voltage indicator.

Speaker beep while operating.

Power-off automatically when idle; manually power-off available.

Negative display function to ensure the accuracy of zero point calibration.

Showing average, max, min value

Principle of Paint Coating Thickness Gauge

The device uses magnetic thickness measurement method, which non-destructively measures thickness of non-magnetic coating (such as: aluminum, chromium, copper, enamel, rubber, paint, etc.) on magnetic metal substrates (such as steel, iron, alloy and hard magnetic steel, etc.).

Magnetic Method (F-type probe)

When the probe contacts the cover layer, the probe and magnetic substrate forms a closed magnetic circuit; Due to the presence of non-magnetic coating, magnetic resistance changes. The thickness of the cover layer can be derived by measuring the change.

Eddy Current Method (NF-type probe)

When the probe contacts the cover layer, the probe and non-magnetic substrate forms Eddy Current and gives feedback to the coil inside the probe.

The thickness of the cover layer can be derived by measuring the feedback.

Technical Data of Paint Coating Thickness Gauge

| Model | TG0001 | TG0002 |

| Principle | Magnetic Method (F-type probe) | Magnetic Method (F-type probe) & Eddy Current Method (NF-type probe) |

| Range | 0-1250um | / |

| Accuracy error |

zero calibration ± (1 + 3% H);

two-point calibration ± [(1% ~ 3% H)] H + 1.5 |

/ |

| Power | 2 * AA battery | / |

| Unit | Um/mil | / |

| Temperature | 0-40 ℃ | / |

| Humidity | ≤85% | / |

| Minimum substrate | 10 * 10mm | / |

| Minimum curvature | 5mm convex; 5mm concave | / |

| Thinnest substrate | 0.4mm | / |

| Weight | 99g | / |

| Size | 110mm * 65mm * 30mm |

/ |

Picture of Paint Coating Thickness Gauge