- Product Details

- {{item.text}}

Quick Details

-

Ejector Stroke(mm):

-

100 mm

-

Ejector Force(kN):

-

38 kN

-

Theoretical Shot Volume(cm³):

-

235 cm³

-

Injection Rate (g/s):

-

128 g/s

-

Injection Weight (g):

-

213 g

-

Screw Speed (rpm):

-

205 - 210 rpm

-

Screw diameter (mm):

-

42 mm

-

Distance between Tie Bars:

-

370*370 mm

-

Weight (KG):

-

34000 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

350 mm

-

Model Number:

-

Z110

-

Brand Name:

-

ONGO

-

Power (kW):

-

14 kW

-

Injection Pressure:

-

227Mpa

-

Max.Mould Height:

-

320mm

-

Min.Mould Height:

-

100mm

-

Machine Dimension(L*W*H):

-

5.68*1.5*2.14M

-

Injection Rate:

-

186 g/s

-

Opening Stroke:

-

280

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

Clamping Force (kN):

-

700 kN

-

After-sales Service Provided:

-

Video technical support

-

Marketing Type:

-

New Product 2020

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

370mm

-

Distance between Tie Bars(Height)(mm):

-

370mm

-

Mold Height(mm):

-

150 - 380 mm

-

Ejector Stroke(mm):

-

100 mm

-

Ejector Force(kN):

-

38 kN

-

Theoretical Shot Volume(cm³):

-

235 cm³

-

Injection Rate (g/s):

-

128 g/s

-

Injection Weight (g):

-

213 g

-

Screw Speed (rpm):

-

205 - 210 rpm

-

Screw diameter (mm):

-

42 mm

-

Distance between Tie Bars:

-

370*370 mm

-

Weight (KG):

-

34000 kg

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

350 mm

-

Model Number:

-

Z110

-

Brand Name:

-

ONGO

-

Power (kW):

-

14 kW

-

Injection Pressure:

-

227Mpa

-

Max.Mould Height:

-

320mm

-

Min.Mould Height:

-

100mm

-

Machine Dimension(L*W*H):

-

5.68*1.5*2.14M

-

Injection Rate:

-

186 g/s

-

Opening Stroke:

-

280

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

Clamping Force (kN):

-

700 kN

-

After-sales Service Provided:

-

Video technical support

-

Marketing Type:

-

New Product 2020

Product Paramenters

|

ITEM

|

Unit

|

Z110

|

|

|

|

|

INJECTIONUNIT

|

|

A

|

B

|

C

|

D

|

|

Screw Diameter

|

mm

|

32

|

35

|

38

|

42

|

|

Shot Volume(Theoretical)

|

cm^3

|

137

|

163

|

192

|

235

|

|

Injection Weight(Ps)

|

g

|

125

|

148

|

175

|

213

|

|

Injection Rate

|

g/s

|

74

|

89

|

105

|

128.1

|

|

Injection Pressure

|

MPa

|

260

|

219

|

186

|

152

|

|

Screw Speed

|

rpm

|

210

|

|

|

|

|

CLAMPING UNIT

|

|

|

|

|

|

|

Clamping Force

|

kN

|

1100

|

|

|

|

|

Open Stroke

|

mm

|

350

|

|

|

|

|

Space Between Tie Bars(W*H)

|

mm

|

370*370

|

|

|

|

|

Max Mould Height

|

mm

|

380

|

|

|

|

|

Min Mould Height

|

mm

|

150

|

|

|

|

|

Ejector Stroke

|

mm

|

100

|

|

|

|

|

Ejector Force

|

kN

|

38

|

|

|

|

|

OTHERS

|

|

|

|

|

|

|

Max.Pump Pressure

|

MPa

|

16

|

|

|

|

|

Pump Motor Power(Servo)

|

Kw

|

14

|

|

|

|

|

Heating Power

|

Kw

|

7.5

|

|

|

|

|

Machine Dimension(L*W*H)

|

M

|

4.4*1.27*1.90

|

|

|

|

|

Oiltank Cubage

|

L

|

230

|

|

|

|

|

Machine Weight

|

T

|

3.4

|

|

|

|

Products Description

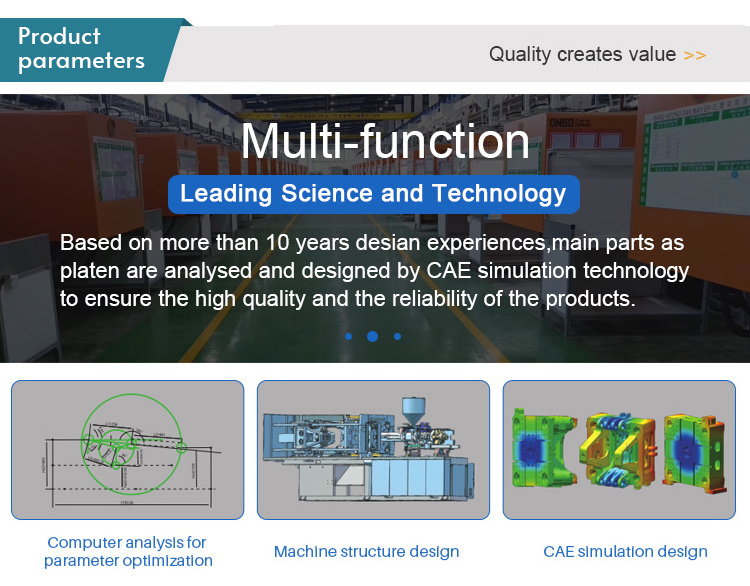

1.INJECTION PREPLASTICATION SEAT WITH OIL COPPER SLEEVE

The preplastication seat reciprocates once in every injection motion. Normal non-automatic lubrication in injection unit can't offer lubrication support to this important motion. Thus, we use oil copper sleeve to make sure that injection reciprocates well.Even without lubricating oil support, it can also slide excellently.Considering cost, however, some materials without oil always cause harmful effect to injection accuracy after a period of time

2.

CLOSED BASE STRUCTURE

Compared with opened structure, the closed base structure is neater and protects components better to avoid any damage by crash. It also improves operation safety

Automatic mould adjustment device is convenient for customer operation.

3.

SEALED STRUCTURE WITH CONE SURFACE

In line with famous international brands, sealed structure with cone surface in connection position of high pressure oil pipe improves sealing reliability greatly

4.

SPRAY PLASTIC IN OIL TANK

Spray plastic in oil tank makes it clean, and what's more, it prevents oil tank to be corroded for long time, extends hydraulic

oil service time effectively, and decreases customer's use-cost

Under the control of ISO 9001 management system, from material selection to processing, production and assembling, each step is inspected strictly.In order to reach 100% eligible rate, the machine shall be given more than 72 h-continuous test in performance reliability.

ONGO 110 TON- 2900 TON

plastic injection molding machine

We can

customize

thin wall injection molding machines for customers according to the characteristics of each customer, and provide overall solutions,We can solve the problem for you at different injection molding industry

Our products can produce any parts, if you have any questions, please click to

contact us

Our services

1.BEFORE SERVICE PURPOSE

Considering reasonable, standard and saving cost scheme for customers, we offer

all-around service and technical support to help them choose correct machine

2.SALES SERVICE

We will provide customer instructions on water

arc elasticity

connection of the

machine, free new machine commissioning, technical training and machine

operation Training.

3.AFTER-SALES SERVICE

Technical support and product maintenance We offer subsequent training and

technical consultation, can even send service engineer to solve the problem at

the customer s factory. After upgrading our product, we will give priority to update

the sold machines according to customer' s requirement

Hot Searches