- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Construction

-

Design Style:

-

Construction

-

Type:

-

Plastic Formwork

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Trico

-

Model Number:

-

TF001

-

Place of Origin::

-

Hebei, China (Mainland)

-

Application::

-

Concrete shuttering Construction

-

Color::

-

gray white

-

Thickness::

-

12- 20mm

-

Brand Name::

-

Trico

-

Material::

-

PP plastic

-

Product name::

-

plastic concrete formwork

-

Size::

-

1220mm*2440mm

-

Type::

-

Waterproof Plastic Template

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

Others

-

Application:

-

Construction

-

Design Style:

-

Construction

-

Type:

-

Plastic Formwork

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Trico

-

Model Number:

-

TF001

-

Place of Origin::

-

Hebei, China (Mainland)

-

Application::

-

Concrete shuttering Construction

-

Color::

-

gray white

-

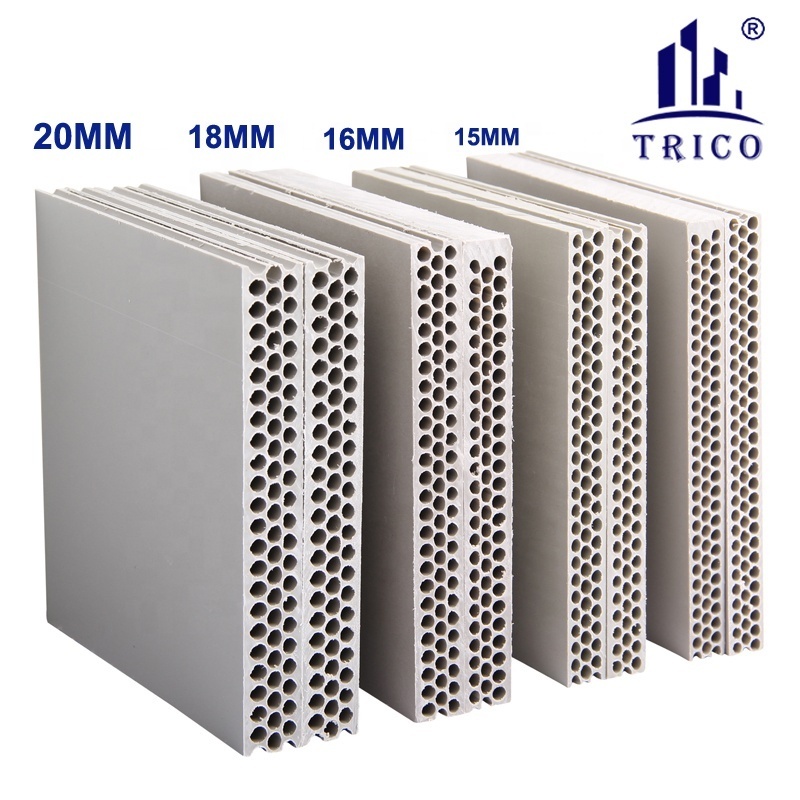

Thickness::

-

12- 20mm

-

Brand Name::

-

Trico

-

Material::

-

PP plastic

-

Product name::

-

plastic concrete formwork

-

Size::

-

1220mm*2440mm

-

Type::

-

Waterproof Plastic Template

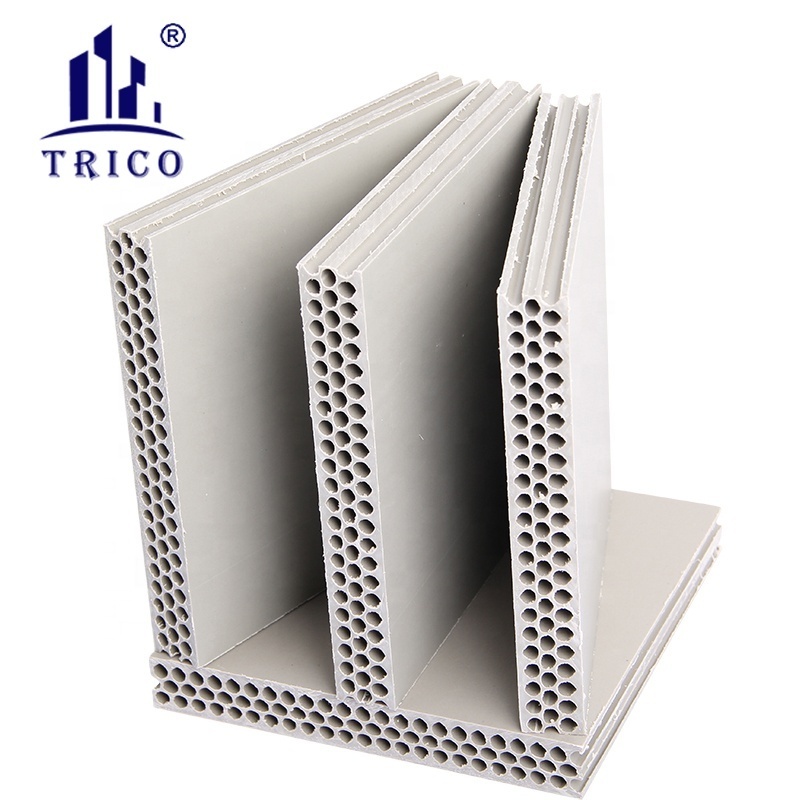

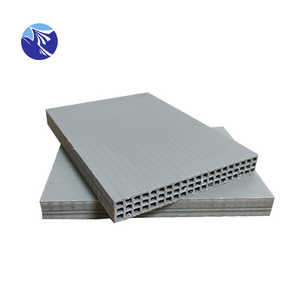

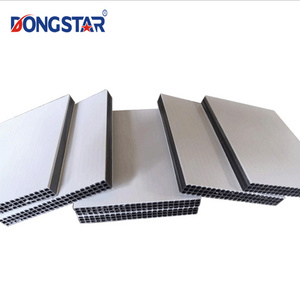

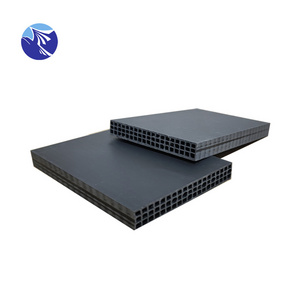

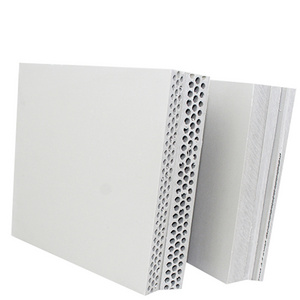

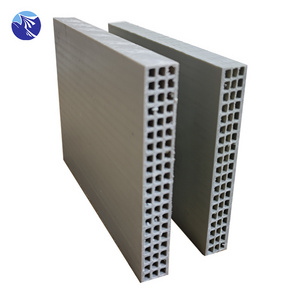

Factory Price Concrete Formwork Plastic Shuttering Formwork PP Hollow Plastic Formwork Board

What is Plastic Formwork?

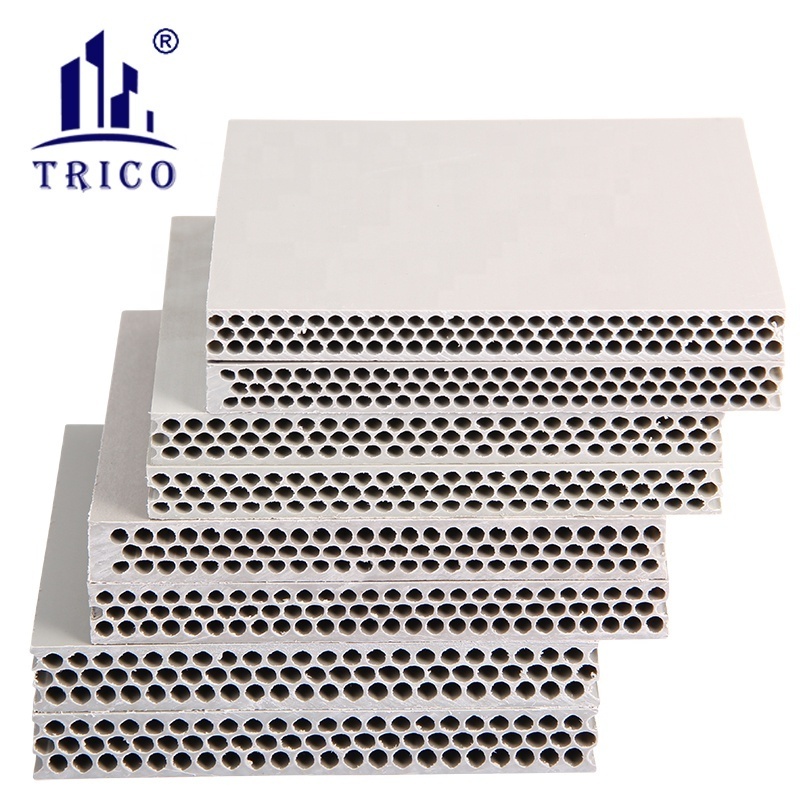

Hollow plastic building formwork is a kind of energy-saving and green environmental protection product, pp plastic combined with macromolecule nano-technology. It is a new product after wood formwork, composite steel formwork, bamboo-wood bonding formwork and all-steel large formwork. It is energy saving and environmental protection,andcan completely replace the traditional steel formwork, wood formwork, square wood. What’s more, its amortization cost is very low.

PP(Polypropylene) Formwork Board Specification

| Size | Weight | Hole type | packaging | 20GP Quantity | 40HQ Quantity |

| 1220x2440x12mm | 21±1kg | Square Hole | 75pcs/Pallet | 600pcs | 1200pcs |

| 1220x2440x14mm | 24±1kg | Round Hole | 65pcs/Pallet | 520pcs | 1040pcs |

| 1220x2440x15mm | 25±1kg | Round Hole | 60pcs/Pallet | 480pcs | 960pcs |

| 1220x2440x16mm | 27±1kg | Round Hole | 55pcs/Pallet | 440pcs | 880pcs |

| 1220x2440x18mm | 31±1kg | Round Hole | 50pcs/Pallet | 400pcs | 800pcs |

| 1220x2440x20mm | 33±1kg | Round Hole | 45pcs/Pallet | 360pcs | 720pcs |

| 915x1830x14mm | 14±1kg | Round Hole | 65pcs/Pallet | 900pcs | 1872pcs |

| 915x1830x15mm | 14.5± 1 kg | Round Hole | 60pcs/Pallet | 900pcs | 1872pcs |

| 915x1830x18mm | 17± 1 kg | Round Hole | 50pcs/Pallet | 600pcs | 1200pcs |

| If Special Sizes need, please contact with us! | |||||

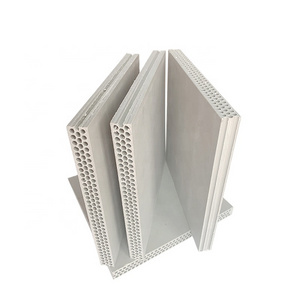

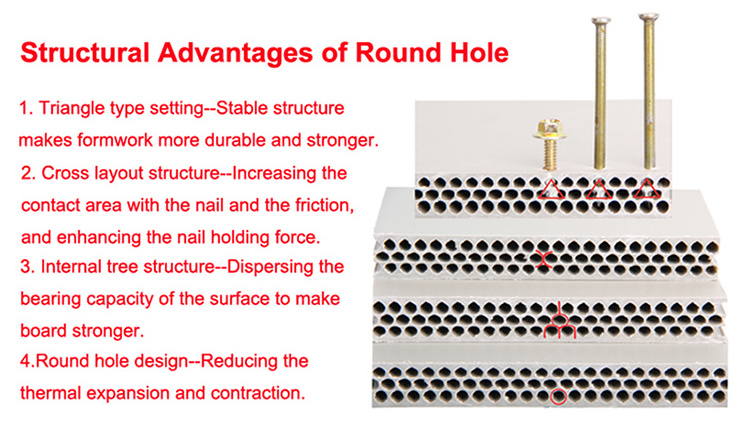

New Desgin&Advantages

1. Round Hole Structural

Square Hole is updated to Round Hole. Structural Advantages make plastic formwork board stronger.

2. Waterproof

Hollow plastic formwork is weather resistance, rain and shine are no longer an issue.

3. Light Weight

It is lighter, easier to carry and release worker from heavy labor.Manual operation, no crane required reducing 20% labor cost than plywood

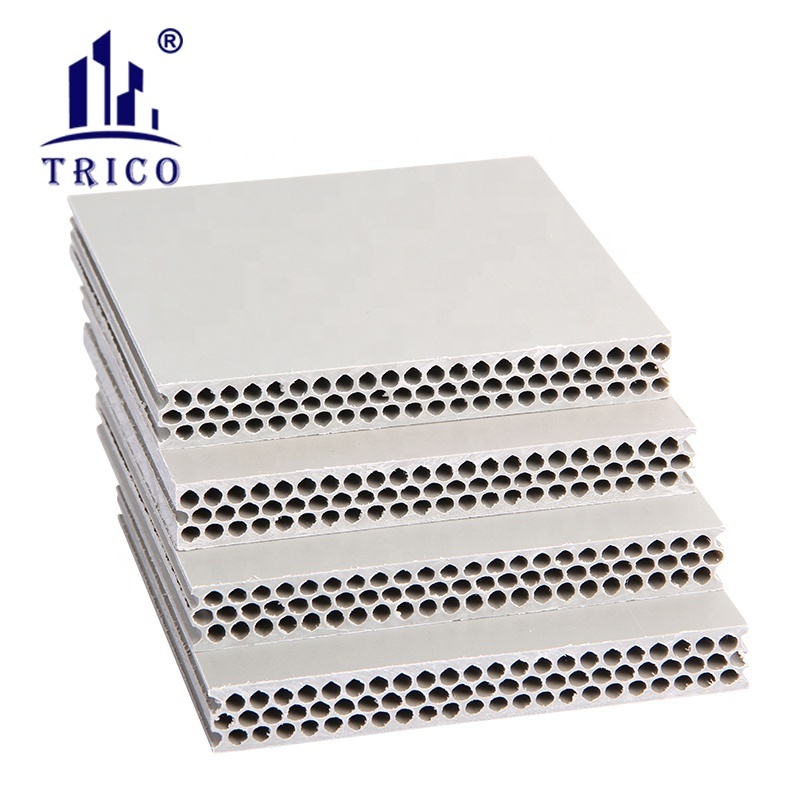

4.Surface does not require maintenance

High pressure water jet flushes surface of the plastic template, but matal formwork requires surface maintenance

5. High Workability

User-friendly, work well with saw,nail,drill,cut,etc. Compatible with other materials such wood,steel,aluminum,etc.

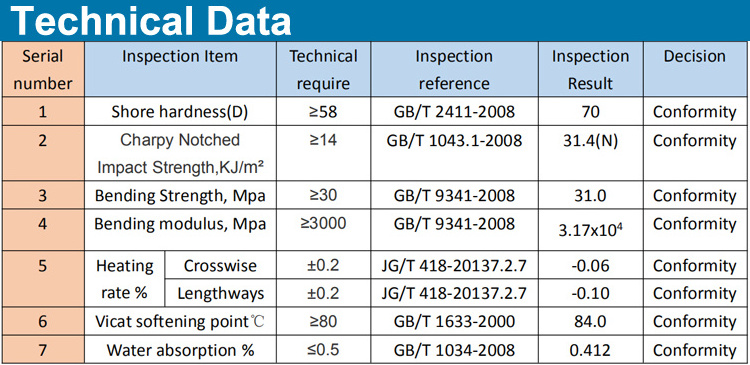

6. High Temperature Resistance

The material is polypropylene, the melting point can be as high as 167℃. PP vicat softening temperature of 150℃.

7. Cost-Saving

One set plastic formwork can finish whole high building 2×35Floors, save 60% total budget than plywood and metal formwork

Formwork Tie Rod System

The Formwork Tie Rod system components include the Tie Rod, Wing Nut, Tie Nut, Anchor Nut, Water Barrier/Water Stop, Washer Plate/Waller Plate, Steel Cone, Plastic Tube and Cone and some European countries also asked for the Flupp Plug ( Rubber Stop).

Wing nuts and Tie rods as a whole facility are used widely in formwork construction.

Formwork Accessories Construction Concrete Hy-rib Permanent Formwork Galvanized Mesh Rib Lath

- Formwork Tie Rod System

- Aluminium Formwork Wall Tie System

- Scaffolding System

- PP Hollow Plastic Formwork

- Steel Formwork Panel with Plywood Forming System

- Other Plastic Building Materials

1. Quality: Strictly control the quality through three levels. First level, quality test on the producing line. Second level, quality test during warehousing. Third level, quality test before loading.

2. Timeliness: 24 hours online. Provide consulting and quotation services for customers all the time.

3. Veracity: Strictly follow the customer standard to ensure the tolerance range and meet customer's requirement.

4. Integrity: If the customer complains about the quality of the products, our company will actively cooperate with them to solve the problem. If it is the responsibility of our company, we will bear the corresponding responsibility and compensation.

5. Longevity: Establish good long-term relationship with customers.