- Product Details

- {{item.text}}

Quick Details

-

MgO Content (%):

-

max 0.5%

-

CaO Content (%):

-

max 0.5%

-

P2O5 Content (%):

-

max 0.45%

-

Place of Origin:

-

China

-

Brand Name:

-

Shengping

-

Model Number:

-

SF- 591

-

Product name:

-

Silica Fume

-

Color:

-

Grey

-

Usage:

-

Cement Concrete Refractory

-

Appearance:

-

Power Silica Fume

-

Shape:

-

Spherical

-

Material:

-

SiO2>92%

-

Packing:

-

25kg/bag

-

Size:

-

Customized Size

-

Keywords:

-

Fused Silica Ceramic Roller

Quick Details

-

SiO2 Content (%):

-

92.0% min

-

Fe2O3 Content (%):

-

max 0.5%

-

Al2O3 Content (%):

-

max 0.7%

-

MgO Content (%):

-

max 0.5%

-

CaO Content (%):

-

max 0.5%

-

P2O5 Content (%):

-

max 0.45%

-

Place of Origin:

-

China

-

Brand Name:

-

Shengping

-

Model Number:

-

SF- 591

-

Product name:

-

Silica Fume

-

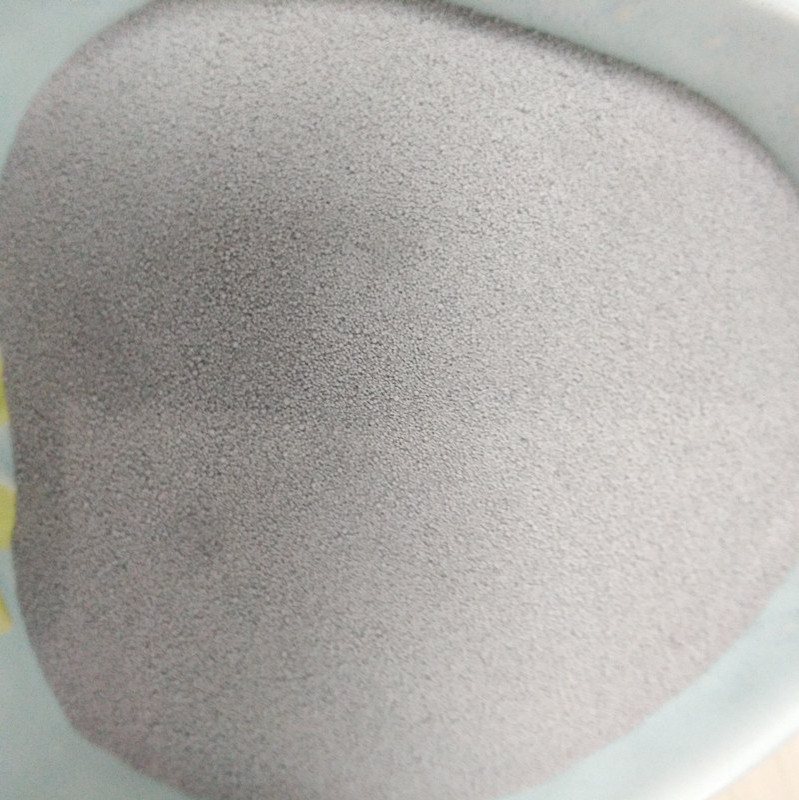

Color:

-

Grey

-

Usage:

-

Cement Concrete Refractory

-

Appearance:

-

Power Silica Fume

-

Shape:

-

Spherical

-

Material:

-

SiO2>92%

-

Packing:

-

25kg/bag

-

Size:

-

Customized Size

-

Keywords:

-

Fused Silica Ceramic Roller

|

Appearance |

Gray powder |

|

Water content |

≤0.5% |

|

Fineness (0.315 mesh) |

≤0.5% |

|

Density |

2.25±0.5g/cm 3 |

|

Cement slurry density |

≤1.60g/cm 3 |

|

Free liquid |

≤1.4 % |

|

Settlement test |

≤2 % |

|

Compression strength,(21Mpa,24h) |

≥8.0 Mpa |

Microsilica

Microsilica also known as Silica Fume. It's collected and packed from silicon metal or ferrosilicon factories directly, the automatic and integrated production process guarantees the consistent quality. Microsilica are classified as various grades and can be used in Concrete, Oilwell cement, Refractory and Fertilizer industries.

Microsilica Silica Fume Micro Silicon Powder.

Micro-silica powder is also called agglomerated silica fume. When iron alloy is used to smelt ferrosilicon and industrial silicon (metal silicon), a large amount of highly volatile SiO2 and Si gas is generated in the ore furnace, and the gas is discharged and air. Rapid oxidation and condensation precipitation. It is a by-product of large-scale industrial smelting. The whole process needs to be recycled by dust-removing environmental protection equipment. Because of its low density, it needs to be encrypted with encryption equipment.

In terms of particle size, the silicon micropowder is processed from natural quartz and has a relatively large particle size of 200 mesh, 300 mesh, 400 mesh, 500 mesh, 600 mesh, 800 mesh, 1000 mesh, 1250 mesh, 3000 mesh, 5000 mesh, 10000 mesh, etc. is a powder state. The micro-silica powder has a fineness of less than 1 μm, more than 80%, and an average particle diameter of 0.1-0.3 μm, which is a gray state.