- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

650*760*980mm

-

Weight (T):

-

0.58 T

-

Power (kW):

-

125

-

Product name:

-

small capacity aluminum melting induction furnace

-

Model:

-

GWL-0.15

-

Rated Power:

-

125 KW

-

Power input voltage:

-

380V

-

Melting frequency:

-

1000Hz

-

Melting rate:

-

0.16T/h

-

Power consumption:

-

650KWh/t

-

Water consumption:

-

3T/h

-

Induction Coil Voltage:

-

750V

-

Hightest temperature:

-

700℃

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

Manufacturer direct sales

-

Brand Name:

-

Sutong

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

650*760*980mm

-

Weight (T):

-

0.58 T

-

Power (kW):

-

125

-

Product name:

-

small capacity aluminum melting induction furnace

-

Model:

-

GWL-0.15

-

Rated Power:

-

125 KW

-

Power input voltage:

-

380V

-

Melting frequency:

-

1000Hz

-

Melting rate:

-

0.16T/h

-

Power consumption:

-

650KWh/t

-

Water consumption:

-

3T/h

-

Induction Coil Voltage:

-

750V

-

Hightest temperature:

-

700℃

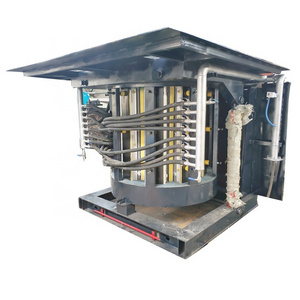

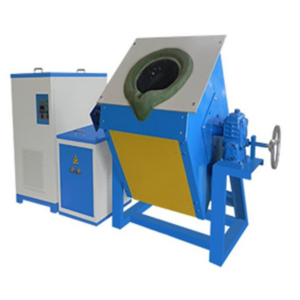

Induction furnace for melting aluminum in 150kg small capacity

Part I. Function

This intermediate frequency induction furnace used for melting ferrous metal, non-ferrous metal

such as copper, aluminum, etc. It can also be used for bending pipe, quenching and all kinds of metal

bar's diathermy.

Part II. Environment and condition usage

1.Temperature should be at 2℃ to 35℃.

2. The relative humidity no more than 90%

3.Installation height no more than 1000m

4.No conductive dust and corrosive gas in working place.

5.No explosion and violent vibration room around the place

6. The temperature of the the cooling water should no less than 10℃, not more than 30℃, hardness<

8 degree, Ph <degrees, pressure>0.2Mpa.

7. Power supply must be ac 50Hz, three-phase, 380V,Voltage fluctuation 370-410Volts.

Part III. Main technical parameter

|

Item |

Unit |

GWL-0.15 |

|

Rated Capacity |

KG |

150 |

|

Rated IF Power |

KW |

125 |

|

Inputting line Voltage |

V |

380 |

|

Furnace Line Voltage |

HZ |

1000 |

|

Melting Rate |

T/H |

0.16 |

|

Power Consumption |

Kwh /t |

650 |

|

Water consumption |

T/H |

4 |

|

Induction Coil Voltage |

V |

1000 |

|

Rated temperature |

℃ |

700 |

|

Transformer Capacity |

KVA |

180 |

Part IV. Instruction of furnace overview

This equipment is composed of furnace body, tilting controller, water cooled cable, capacitor, medium

frequency, water cooling plant.

1.Furnace Body

Furnace structure has four type, aluminum reduction tilting furnace, aluminum hydraulic furnace,

magnetic shielding steel furnace and hydraulic steel furnace reduction tilting furnaces equip with

reduction machine, hydraulic tilting furnaces equip with hydraulic pump and work station. The whole

sets generally have two furnaces using for melting and maintenance.

Induction coil installs in the central of t h e furnace, it has spiral body with rectangular empty brass

circle around, the pipe center should be cooled with water. Copper bar outside induction coil will

connect with water-cooling cable. The lining closes to induction coil, which made by burden,

the method you can find in related parts below.

2.Tilting Controller

The controller is a control box for tilting furnace. The switch on the controller can choose furnaces and

the button can move around through the rubber soft line, and also control the furnace for tilting and

r esetting(this part should be installed by users themselves).

3. Water-cooled cable

Water cooled cable is made of soft copper wire, hose,cable end, through them to conne c t with

c apacitor and furnace.

4. Capacitors

Capacitors compose of electric heat, holder, the converge-wires. it supply power.

5. Medium Frequency power cabinet

Medium frequency power cabinet will transmute three-phase ac power frequency into medium

ac power.

6.Water-cooling plant(Prepared by user)

Water cooling plant include water inlet and outlet water tank, it supply for an induction coil. water-cooled electric cable and cooling water in c a pacitor, can be divided into five ways, usua l ly using only

three way(once melting furnace does not work the water in the induction coils and cooling cable can

be close down through the valve).

Quality control of stainless steel melting furnace

To ensure that customers use our induction fu r nace with no worries, hereby we warrant:

1. We strictly select good material to ensure the reliable quality.

2. Not only in the selection of materials, but also in every production procedures, we strictly act

according to the ISO9001 standard, and control by full-scale inspection.

3. The Technical and specialized support from us will be available.

4. The upgraded products information will be timely supplied.