- Product Details

- {{item.text}}

Quick Details

-

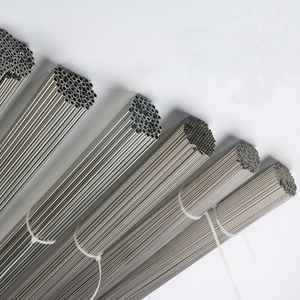

Outer Diameter:

-

3 - 80 mm

-

Thickness:

-

0.5 - 8 mm

-

Secondary Or Not:

-

Non-secondary

-

color of steel tube:

-

slivery

-

tolerance of steel tube:

-

+/-0.03mm

-

shape of steel tube:

-

round pipe

-

technology of steel tube:

-

cold drawn & cold rolled

-

Usage:

-

Drill Pipe, Fluid Pipe, Hydraulic Pipe, Oil Pipe, Structure Pipe

-

Product name:

-

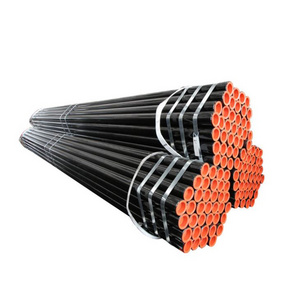

cold drawn astm a106/a53 gr.b st 53 seamless steel pipe/tube

-

Length:

-

1-12m

-

Material:

-

10#.20# 45# 16Mn etc

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Polishing

-

Place of Origin:

-

Jiangsu, China

-

Outer Diameter:

-

3 - 80 mm

-

Thickness:

-

0.5 - 8 mm

-

Secondary Or Not:

-

Non-secondary

-

color of steel tube:

-

slivery

-

tolerance of steel tube:

-

+/-0.03mm

-

shape of steel tube:

-

round pipe

-

technology of steel tube:

-

cold drawn & cold rolled

-

Usage:

-

Drill Pipe, Fluid Pipe, Hydraulic Pipe, Oil Pipe, Structure Pipe

-

Product name:

-

cold drawn astm a106/a53 gr.b st 53 seamless steel pipe/tube

-

Length:

-

1-12m

-

Material:

-

10#.20# 45# 16Mn etc

GB 10#

| Chemical Composition(%) | Mechanical Property | |||||||||

| C | Si | Mn | S | P | Cr | Ni | Cu | Mo | Yield Strength | Tensile Strength |

| ( σs ) | ( σb ) | |||||||||

| 0.07~0.14 | 0.17~0.37 | 0.35~0.65 | ≤0.04 | ≤0.35 | ≤0.15 | ≤0.25 | ≤0.25 | / | ≥205(25) (MPa) | ≥ 410(42) |

| (MPa) | ||||||||||

| End Shape | Beveled end, plain end, vanished, or adding plastic caps to protect the two ends as per customer's requirements | |||||||||

| Surface | Oiled, Galvanized, Phosphate etc | |||||||||

| Treatment | ||||||||||

| Technique | Cold drawn | |||||||||

| Application | 1. Automotive and mechanical pipes | |||||||||

| 2. Petroleum cracking pipes | ||||||||||

| 3. High Pressure Boiler Pipe | ||||||||||

| 4. Low and middle pressure fluid transportation pipeline | ||||||||||

| 5. Chemical fertilizer equipment pipes | ||||||||||

| 6. Heat exchanger pipes | ||||||||||

| Delivery | 1. BK (+C) | No heat treatment after last cold forming process. | ||||||||

| Conditions | 2. BKW (+LC) | After last heat treatment there is a light finishing pass (cold drawing) | ||||||||

| 3. BKS (+SR) | After the final cold forming process the tubes are stress relieve annealed. | |||||||||

| 4. GBK (+A) | After the final cold forming process the tubes are annealed in a controlled atmosphere. | |||||||||

| 5. NBK (+N) | After the final cold forming process the tubes are annealed above the upper transformation point in acontrolled atmosphere. | |||||||||

| Package | 1. Bundle Packing. | |||||||||

| 2. Plain end or vanished as per customer's request. | ||||||||||

| 3. Wrapped in waterproof paper. | ||||||||||

| 4. Sackcloth with several steel strips. | ||||||||||

|

5. Pack in heavy tri-wall boxes. |

||||||||||

teel tube steel tube steel tube steel tube steel tube steel tube steel tube steel tube steel tube steel tube steel tube steel tube steel tube steel tube steel tube steel tube steel tube steel tube

Hot Searches