2.Visible process parameters ensure perfect welding quality, small deformation, and high penetration.

3.Supported languages include Chinese,English, Korean,Russian, Japanese,German, French, ltalian, Spanish,Portuguese,Turkish, Greek, Czech,Slovak,Polish,Thai,Vietnamese, and Romanian.

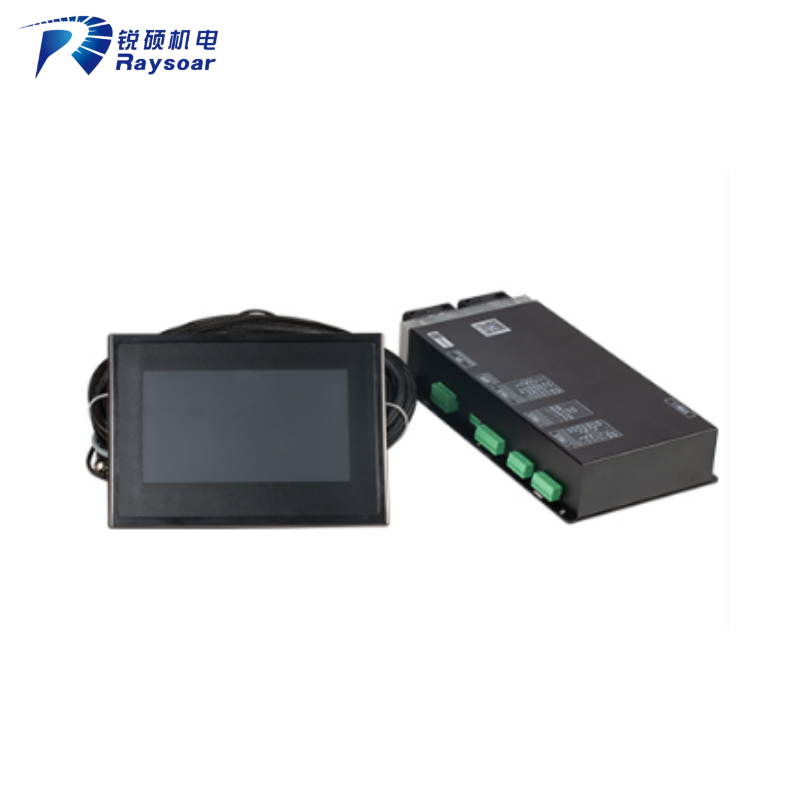

4.The SUP21T handheld welding head control panel's version number is V5.8-81-701.You can check the system version through the monitoring page, and the last three digits indicate the control panel version.