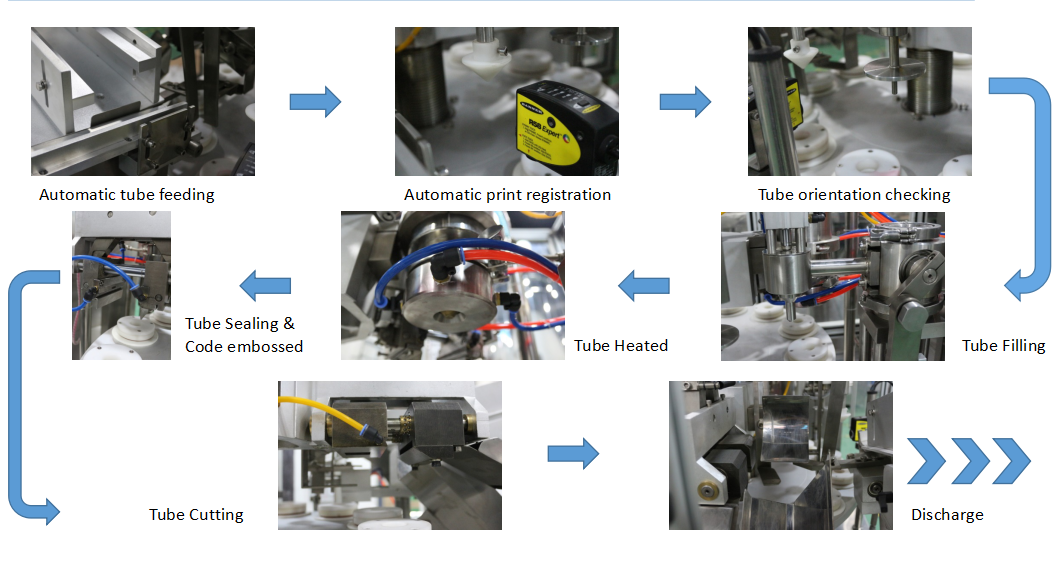

This machine is designed for plastic tube and multiple tube filling and sealing in cosmetic, pharmacy, foodstuff, adhesives etc industries. Its operating principle is to put the pipes which is in the feeder hopper in

to

the

first

service position filling model individually, to invert with rotating disk, to test nomenclature plate in pipe when inverting to the

second

, to fill with nitrogen gas into pipe .

in the

third

, to fill with desired substance .

in the

fourth

, then to fix the heating, folding, jamming,number printing, cooling, slivers trimming etc service position, to export the finished products when inverting to the last service position so the twelfth. Every pipe should take such series process to filling, sealing to completion.