- Product Details

- {{item.text}}

Quick Details

-

Width:

-

200-810mm

-

Length:

-

Request

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Kangheng

-

Model Number:

-

SAE 4140

-

Application:

-

Tool Steel Plate

-

Item Name:

-

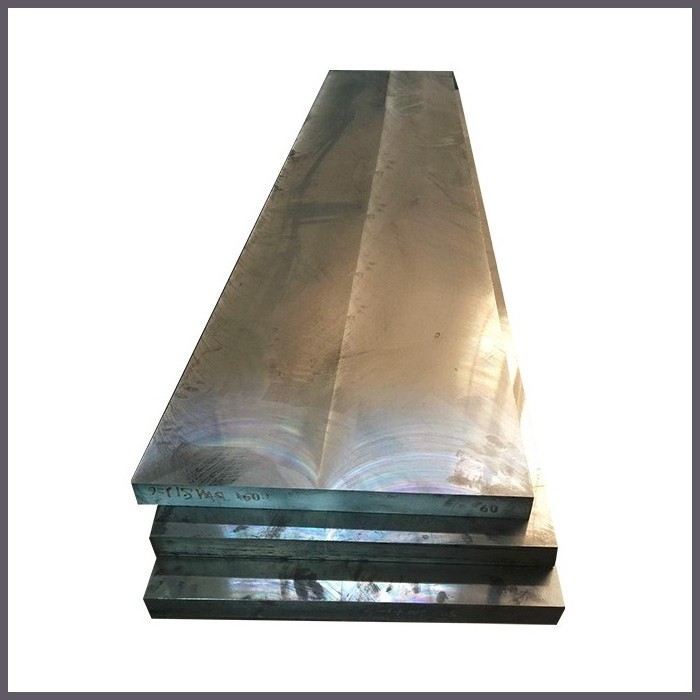

Hot forging die steel alloy special 4140 steel plate

-

Surface treatment:

-

Black/Grinded/Machined/Turned

-

Production route:

-

EF/EAF+LF+VD/ESR

-

Quality inspection:

-

UT, Chemical test, Microstructure, Physical properties etc.

-

UT test standard:

-

SEP1921-84 class3 C/c to D/d

-

Certification:

-

ISO9001

-

Service:

-

Free Samples and Accept Trial Order

-

Heat Treatment:

-

Annealed/Quenching/Tempering

Quick Details

-

Standard:

-

AiSi

-

Grade:

-

Alloy Steel SAE 4140, Hot Forged Flat Bar SAE 4140

-

Tolerance:

-

±1%

-

Width:

-

200-810mm

-

Length:

-

Request

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Kangheng

-

Model Number:

-

SAE 4140

-

Application:

-

Tool Steel Plate

-

Item Name:

-

Hot forging die steel alloy special 4140 steel plate

-

Surface treatment:

-

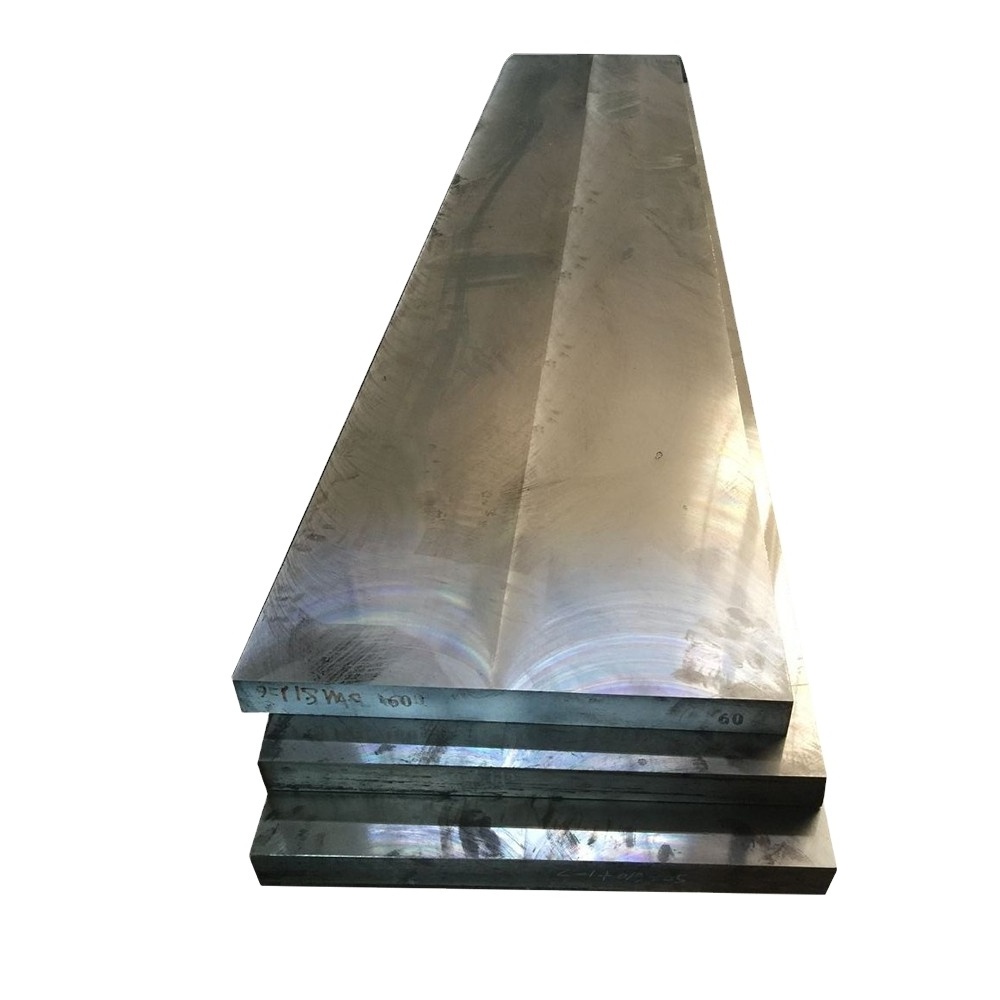

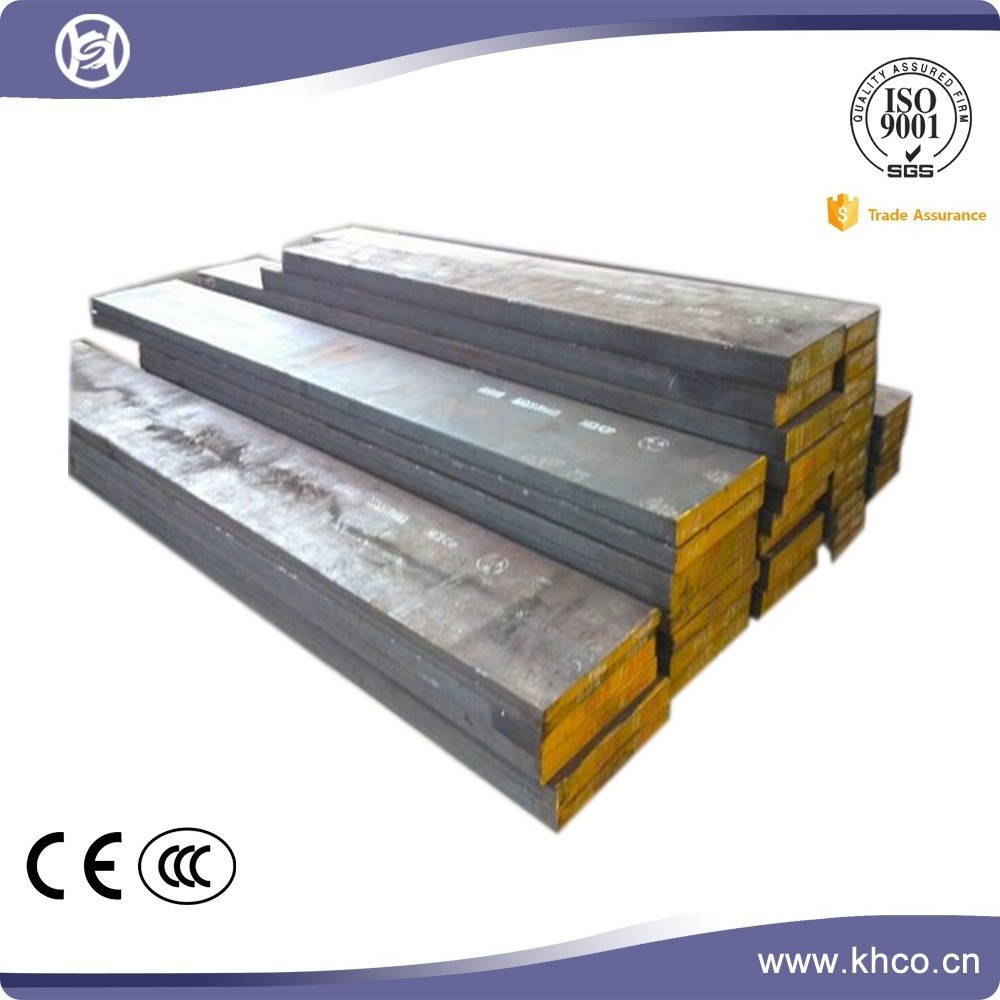

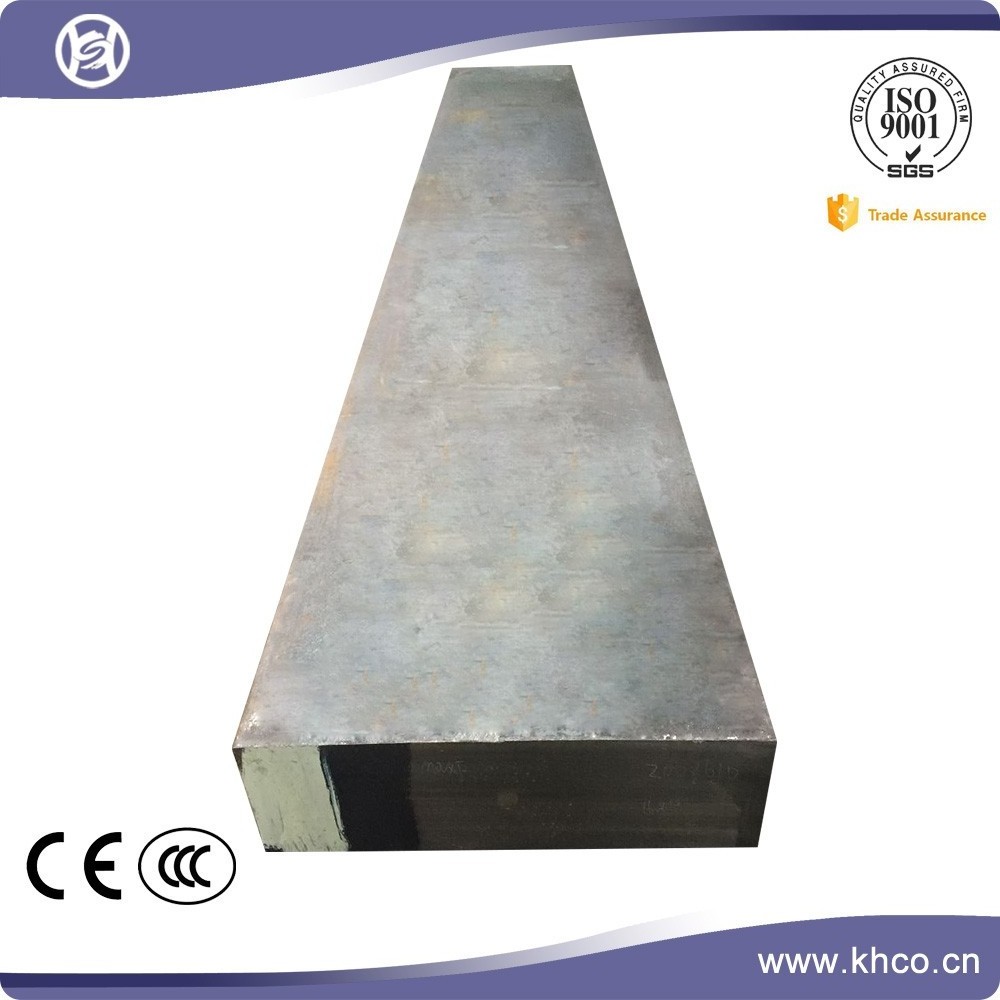

Black/Grinded/Machined/Turned

-

Production route:

-

EF/EAF+LF+VD/ESR

-

Quality inspection:

-

UT, Chemical test, Microstructure, Physical properties etc.

-

UT test standard:

-

SEP1921-84 class3 C/c to D/d

-

Certification:

-

ISO9001

-

Service:

-

Free Samples and Accept Trial Order

-

Heat Treatment:

-

Annealed/Quenching/Tempering

Hot forging die steel alloy special 4140 steel plate

Hot forging die steel alloy special 4140 steel plate

| Size of SAE 4140 (Can be Customised) | |||

| Round Bar | Diameter(mm): | Hot Forged: φ50-500 | Length(mm):2000-5800 |

| Hot Rolled:≤50 | |||

| Steel Plate | Thickness(mm): | Hot Forged:≥20 | Width(mm):200-810 |

| Hot Rolled:≤20 | |||

| Steel Type | |||

| AISI | GB | W-Nr | JIS |

| 4140/B7 | 42CRMO4 | 1.7225 | SCM440 |

| Chemical Composition | |||||||

| C | Si | Mn | P | S | Cr | Mo | V |

| 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.030 | ≤0.030 | 0.80-1.10 | 0.15-0.25 | / |

| GB 42CrMo4/W-Nr 1.7225 /ASTM B7/4140/JIS SCM440 | |||

| Characteristics: | |||

| 1.High hardenability and good toughness; | |||

| 2.Good torsional strength and good fatigue strength. | |||

| Applications: | |||

| 1.Excellent material for gears, piston pins, crankshafts,and shafts; | |||

| 2.Vehicles, engines and machines; | |||

| 3. For parts of larger cross-sections, crankshafts, gears. |

| Noted | |||

|

(1) Payment : 1.By confirmed, 100% valum irrevocable, letter of credit without recourse, Allowing partial shipment and transhipment, payable at sight presentation of shipping. |

|||

| 2.By T/T payment: 30% payment in deposited, 70% payment before shipment. | |||

| (2) Delivery Time : 40 days after received the buyer's L/C or T/T deposite payment. | |||

| (3) Delivery Port :Wuhan/Shanghai/Tianjin | |||

| (4) Original Place : Hubei ,China . | |||

| (5) Process: Electric furnace melted, forged and annealed, round bar turned. | |||

| (6) Tolerance: Dia -0/+ 0~5mm, Thickness -0/+ 0~5mm, Width: -0/+ 0~10mm. | |||

| (7) Hardness: Annealed HBS 217 max . | |||

| (8) UT Test: SEP 1921/84/2 C/c class. | |||

| (9) Allowance on quantity/weight: -/+ 10% per item. | |||

|

(10) Package: Seaworthy Packing. |

Hot Searches