- Product Details

- {{item.text}}

Quick Details

-

Ejector Stroke(mm):

-

300 mm

-

Ejector Force(kN):

-

275 kN

-

Theoretical Shot Volume(cm³):

-

4329 cm³

-

Injection Rate (g/s):

-

1040 g/s

-

Injection Weight (g):

-

4065 g

-

Screw diameter (mm):

-

105 mm

-

Screw L/D Ratio:

-

21.4

-

Distance between Tie Bars:

-

1010*1010

-

Weight (KG):

-

35500

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

1025 mm

-

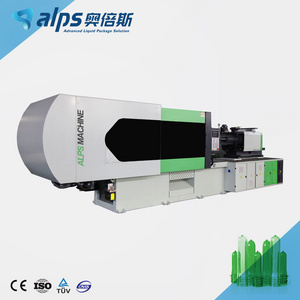

Model Number:

-

BS800-III

-

Brand Name:

-

BORCHE

-

Power (kW):

-

40.9 kW

-

Clamping Force (kN):

-

8000 kN

-

Certification:

-

CE ISO9001

-

Machine weight:

-

35500KG

-

Injection pressure:

-

133MPa

-

Color:

-

Customized

-

Language:

-

English

-

Oil Tank Capacity:

-

1400L

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

1010 mm

-

Distance between Tie Bars(Height)(mm):

-

1010 mm

-

Mold Height(mm):

-

380 - 975 mm

-

Ejector Stroke(mm):

-

300 mm

-

Ejector Force(kN):

-

275 kN

-

Theoretical Shot Volume(cm³):

-

4329 cm³

-

Injection Rate (g/s):

-

1040 g/s

-

Injection Weight (g):

-

4065 g

-

Screw diameter (mm):

-

105 mm

-

Screw L/D Ratio:

-

21.4

-

Distance between Tie Bars:

-

1010*1010

-

Weight (KG):

-

35500

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

1025 mm

-

Model Number:

-

BS800-III

-

Brand Name:

-

BORCHE

-

Power (kW):

-

40.9 kW

-

Clamping Force (kN):

-

8000 kN

-

Certification:

-

CE ISO9001

-

Machine weight:

-

35500KG

-

Injection pressure:

-

133MPa

-

Color:

-

Customized

-

Language:

-

English

-

Oil Tank Capacity:

-

1400L

BS

-III Machine Features

Injection Unit

Do

uble-injection cylinder

Double-carriage cylinder

Nozzle purge cover

Linear guide ra

il

Three kinds screw as option for every machine

Nozzle contact force adjustment function

Nozzle central device

Barrel cover

Low-speed high-torque Hydraulic motor

RPM sensor (4 times / 1 round)

Removable hopp

er rail

Clamping Unit

Mould fixing designation referring Euromap 2

Robot mechanical interface referring Euromap 18

Ejection distribution referring Euromap 2

Big operation room for ejection

Anti-pitch slider (above BT150)

Clamp transducer connect directly to cross head of toggle

Central oil lubrication

Hydraulic Unit

Variable displacement pump

One set sets core puller

Oil temperature alarm

Oil level meter and oil temperature indicator

Low pressure clamping function

Quick-clamping

Mould height adjustment by gear mechanism

Back-pressure control function

Suckback

Pressure relief valve for carriage moving (below BT650)

Oil cooler

High-precision bypass filter (above BT480)

Fiter block alarm (above BT800)

Self-sealing filter (above BT800)

Nozzle moving function √

Electric and control part

KEBA controller

Language (Chinese and English)

Data lock and operation password

SPC quality management

Alarm and parameter resetting record

PID temperature control

Screw protection function

Support current/voltage analogue output

Clamping force auto-adjust

CAN interface

Injection 6 stage/pressure holding 5 stage/charge 5 stage

Mold clamp/open 5 stage /ejection 2 stage

MOVING PL ATEN CLA MPING

.1-Tie bars move across clamping cylinder, no touch with

seals, lessen pressing leakage; Module type clamping

cylinder, can be assembled and disassembled together,

easy for maintenance.

2-Pistons of four cylinders are controlled separately, which can adjust the locking position precisely, and assure fast

and precise locking.

3-Clamping cylinder assembled in the moving platen can

balance the load of mold, avoiding mold forward, improve

stability of moud open and clamping movement.

SUPER LONG LASTING TIE BAR

During high pressure locking, four tie bars under equal

force, no unbalance loading occured, avoiding tie bar

broken theoretically.

1-Both carriage cylinder and injection adopt linear guider, which guarantee stable and fast movement, injection

supporting made by one piece casting, is rigid and

compact.

2-Double carriage cylinder insures injection unit better

centering, and movement stable.

Mold platen Drawing

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

PET preform

91.8%

Response Rate

Food container

91.8% Response Rate

Hair dryer fitting

91.8% Response Rate

Blood collection tube

91.8%

Response Rate

Pipe joint

91.8%

Response Rate

Feeding bottle

91.8%

Response Rate