- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Nanyang

-

Voltage:

-

220V/380V/415V/440V

-

Power:

-

660000

-

Dimension(L*W*H):

-

oem

-

Weight:

-

21000 kg

-

Warranty:

-

one year

-

Diameter of welded tube:

-

19-63.5mm

-

Wall Thickness of welded tube:

-

0.8-3.0mm

-

Milling speed:

-

30-120M/Min

-

Main motor power:

-

250KW

-

High frequency power:

-

300KW

-

Annual output:

-

24700t

-

Pipe shape:

-

Round Square Rectangle Pipe

-

Cutting system:

-

Cold Cutting Saw/Friction Saw

Quick Details

-

Pipe Material:

-

Carbon steel

-

Marketing Type:

-

Hot Product 2024

-

Production Capacity:

-

/

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Nanyang

-

Voltage:

-

220V/380V/415V/440V

-

Power:

-

660000

-

Dimension(L*W*H):

-

oem

-

Weight:

-

21000 kg

-

Warranty:

-

one year

-

Diameter of welded tube:

-

19-63.5mm

-

Wall Thickness of welded tube:

-

0.8-3.0mm

-

Milling speed:

-

30-120M/Min

-

Main motor power:

-

250KW

-

High frequency power:

-

300KW

-

Annual output:

-

24700t

-

Pipe shape:

-

Round Square Rectangle Pipe

-

Cutting system:

-

Cold Cutting Saw/Friction Saw

Products Description

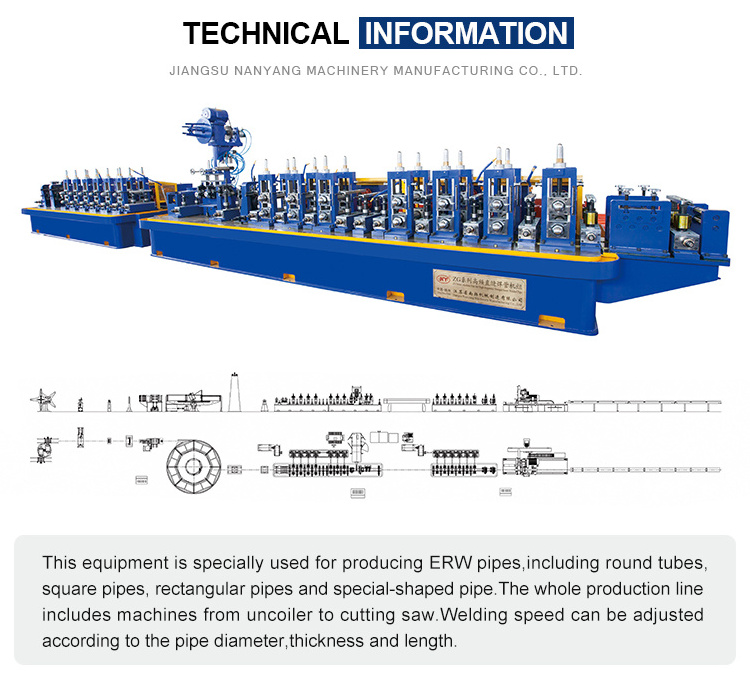

Nanyang surface tube making machine erw steel tube pipe mill processing line

|

Model

|

Welded pipe diameter

|

Welded pipe wall thickness

|

Welding speed

|

Main motor power

|

High frequency power

|

|

ZG16

|

Φ8~Φ25mm

|

δ0.25~1.0mm

|

30~120M/min

|

37KW

|

100KW

|

|

ZG25

|

Φ8~Φ32mm

|

δ0.3~1.3mm

|

40~120M/min

|

45KW

|

100KW

|

|

ZG32

|

Φ13~Φ40mm

|

δ0.4~2.0mm

|

30~110M/min

|

110KW

|

150KW

|

|

ZG45

|

Φ16~Φ50.8mm

|

δ0.5~2.5mm

|

30~110M/min

|

132KW

|

200KW

|

|

ZG50

|

Φ19~Φ63.5mm

|

δ0.6~3.0mm

|

30~100M/min

|

160KW

|

200KW

|

|

ZG60

|

Φ19~Φ63.5mm

|

δ0.7~3.5mm

|

30~100M/min

|

200KW

|

250KW

|

|

ZG76

|

Φ25~Φ90mm

|

δ0.9~4.0mm

|

20~80M/min

|

200KW

|

300KW

|

|

ZG90

|

Φ38~Φ127mm

|

δ1.2~4.5mm

|

20~70M/min

|

132KW×2

|

400KW

|

|

ZG115

|

Φ48~Φ127mm

|

δ1.4~5.0mm

|

20~60M/min

|

160KW×2

|

400KW

|

|

ZG165

|

Φ50.8~Φ165mm

|

δ1.8~6.0mm

|

15~50M/min

|

200KW×2

|

500KW

|

|

ZG219

|

Φ89~Φ219mm

|

δ2.0~8.0mm

|

12~40M/min

|

250KW×2

|

600KW

|

|

ZG273

|

Φ114~Φ273mm

|

δ2.5 ~10.0mm

|

10~30M/min

|

132KW×2, 160KW×2

|

800KW

|

|

ZG325

|

Φ168~Φ325mm

|

δ3.0 ~12.0mm

|

10~30M/min

|

160KW×2, 200KW×2

|

1000KW

|

|

ZG530

|

Φ219~Φ530mm

|

δ4.0 ~16.0mm

|

10~30M/min

|

75KW×5, 160KW×8

|

1500KW

|

ABOUT THE PRICE

Firstly, we provide free customized solution services!

The final price shall be based on the proposed quotation!

The final price shall be based on the proposed quotation!

Forming Section

Function: to form the steel strips into a round shape and ready to be welded.

Advantage:

>Advanced forming technology

>One-stage molding platform

>Reliable quality gearbox

>Siemens Beide motor

Welding Section

Function: To weld the edges of the steel strips together by H.F. Welder (the H.F. Welder is not included).

Forming & Sizing Mill

Function: After welding, the pipes are almost the round shape, but it still needs to be modified into a regular round shape.

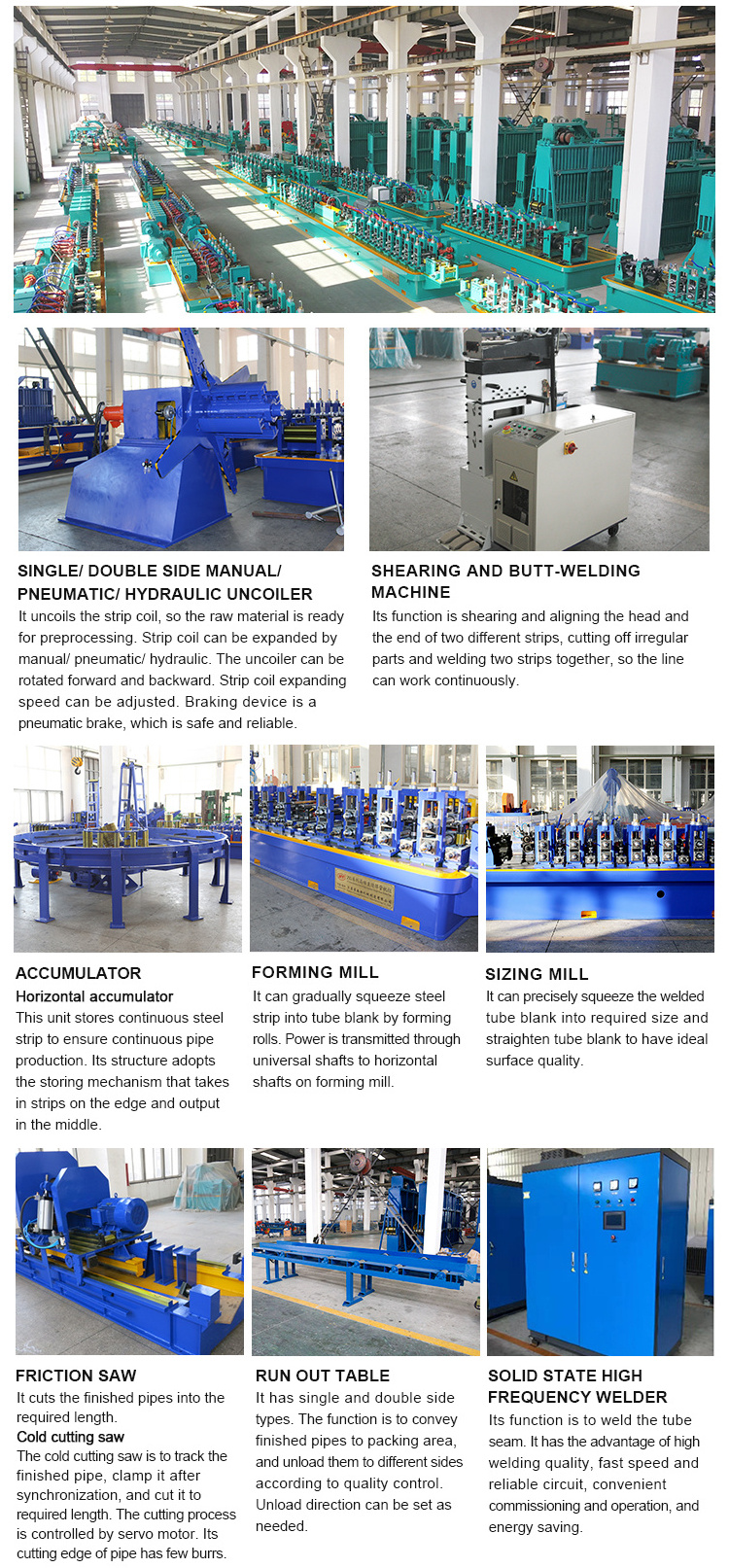

Standard configuration:

1. Uncoiler: Mechanical tension bridle manual adjustment .

2. Horizontal and vertical holder: Passed heat treatment to make black. The holder will rust protection when used.

3. Bearing : Used deep groove ball bearing

4. Welding : Argon welding machine (500A) .

5. Grinding head: Manual by hand to debugging.

6. Cutting machine: Abrasive cutting machine.

7. Drive motor used Siemens brand, grinding motor used Kaiyuan brand.

Customer Feedback

Recommend Products

Hot Searches