- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/400V/415V

-

Dimension(L*W*H):

-

5500*2200*2100MM

-

Weight:

-

500 kg

-

Name:

-

Livestock animal feed mixer

-

Application:

-

Poultry Farm

-

Capacity:

-

500-2000KG/h

-

Usage:

-

Homemade pellet mill plan

-

raw materail:

-

Sawdust, leaves, rice Husk, wood

-

Color:

-

Clients' Requirement

-

Function:

-

pellet making

-

Material:

-

Alloy Steel

-

Motor:

-

Chinese Brand

-

countries:

-

South Africa, UK, US, Europe

Quick Details

-

Max. Capacity:

-

500 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

AOLS

-

Voltage:

-

380V/400V/415V

-

Dimension(L*W*H):

-

5500*2200*2100MM

-

Weight:

-

500 kg

-

Name:

-

Livestock animal feed mixer

-

Application:

-

Poultry Farm

-

Capacity:

-

500-2000KG/h

-

Usage:

-

Homemade pellet mill plan

-

raw materail:

-

Sawdust, leaves, rice Husk, wood

-

Color:

-

Clients' Requirement

-

Function:

-

pellet making

-

Material:

-

Alloy Steel

-

Motor:

-

Chinese Brand

-

countries:

-

South Africa, UK, US, Europe

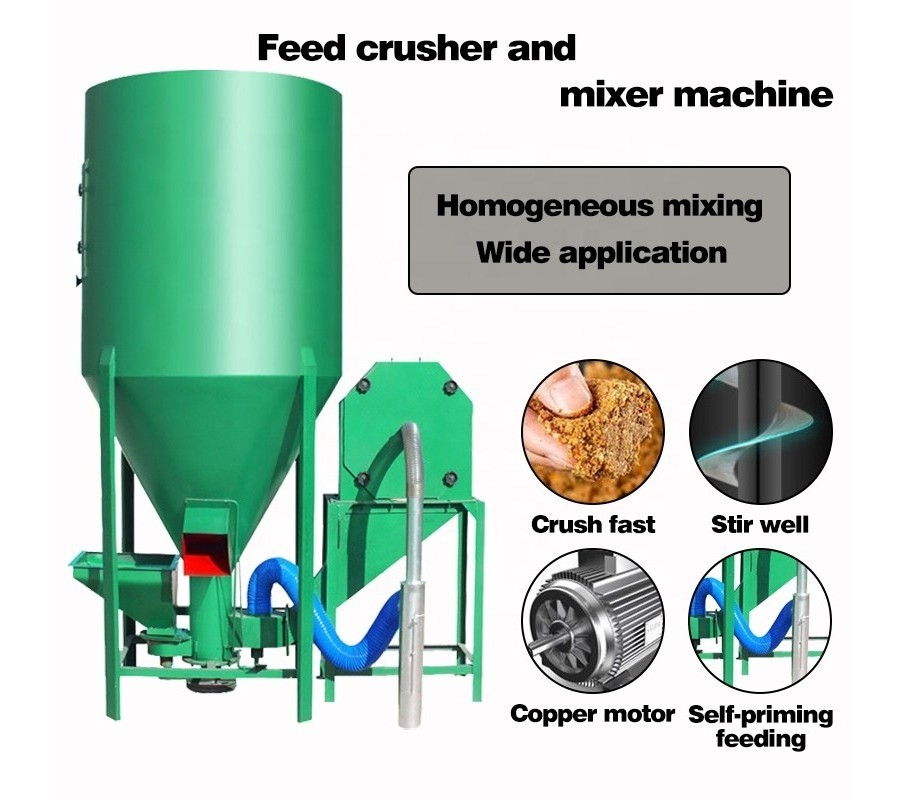

Poultry Feed Pellet Maker Cow Feed Animal Food Pellet Making Machine Mixer and Pellet Machine for animal feed

vertical animal poultry Feed Mixer Grinder Machine is a complete set of feed processing equipment integrating crushing and mixing. It is suitable for small and medium-sized farms and feed processing plants. You could have own feed production with it and no need to buy feed from the market. It is the best way to make the chickens organic.

One worker can take care of the production of feed. And Feed Machine For Farm Use is very easy to assemble and operation.

It is a combined feed mill and mixer and the mixer has vacuum to move the grains from ground to mill and then to mixer. We also have videos of how they work together.

| Model |

Mixer power (KW) |

Material and thickness |

Grinder power (KW) |

Crushing chamber diameter |

Material and thickness |

Size(mm) |

Output (T/H) |

Weight (KG) |

| HH-250 | 3 |

Q235/1.8mm |

7.5 | 530 |

Q235/2.75mm |

1600*800*1950 |

0.4-0.8 |

260 |

|

HH-250 (Single phase electric) |

3 | Q235/1.8mm | 3 | 400 |

Q235/2.75mm |

1580*800*1950 |

0.3-0.5 |

240 |

| HH-500 | 3 | Q235/1.8mm | 7.5~11 | 530 |

Q235/2.75mm |

1800*1000*2300 |

0.5-1.5 |

340 |

|

HH-500 (Single phase electric) |

3 | Q235/1.8mm | 3 | 400 |

Q235/2.75mm |

1780*1000*2300 |

0.3-0.6 |

270 |

| HH-1000 | 3 | Q235/1.8mm | 7.5~11 | 530 |

Q235/2.75mm |

2050*1250*2750 |

1.0-2.0 |

420 |

| HH-1500 | 4 | Q235/1.8mm | 11~15 | 530 |

Q235/2.75mm |

2250*1450*2900 |

1.5-2.5 |

540 |

| HH-2000 | 4 | Q235/2.35mm | 11~15 | 530 |

Q235/2.75mm |

2500*1700*3100 |

1.5-3.0 |

580 |

| HH-3000 | 5.5 | Q235/2.35mm | 15 | 530 |

Q235/2.75mm |

2600*1800*3600 |

2.0-3.5 |

650 |

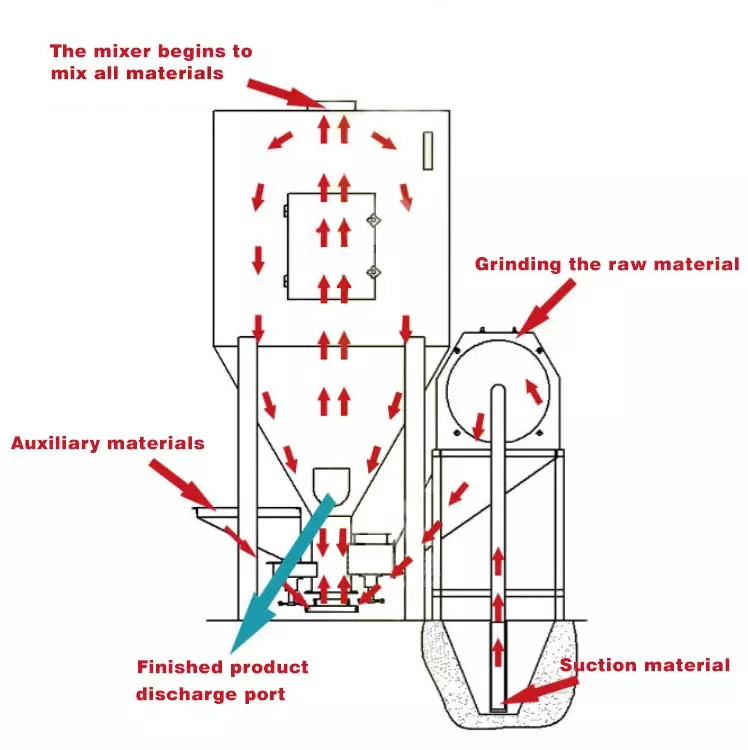

Working principle:

The shell of the feed crushing mixer is welded with high-quality materials. The feed inlet is on the upper part of the crusher, which can be matched with various forms of feeding structures. The hammers are arranged symmetrically; Under the action of hammer blow and sieve plate friction, the material is gradually crushed and discharged through the bottom outlet under the action of centrifugal force and airflow.

2. Mixing mechanism: When the material propeller rotates, the material is forcibly fed into the conveying pipe by the impeller chamber, and when it is lifted to the upper end by the rotary conveyor, the material in the mixing box is lifted up and down and the circular rotation is scattered and turned to form a mixture. The process, the effect is very uniform, very ideal.

Package

1.Machines will be packed in standard and quantities boxes ,the production will have a safe and complete journey from our factory to your place.

2.Packaging details standard export wooden case or in container.

Shipping

1,We will serve your shipping method about ocean transport ,air lift ,freights and so on.

2,The delivery time is usually 7-15 working days upon receipt of your payment.