- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

USUN

-

Model Number:

-

GB40

-

Place of Origin:

-

Guangdong, China

-

Horsepower:

-

None

-

Cable Length:

-

None

-

Outlet Size:

-

None

-

Power:

-

None

-

motor:

-

None

-

Material:

-

Stainless steel Cap and High pressure chamber

-

Pump Type:

-

Horizontal or Vertical installation

-

Product name:

-

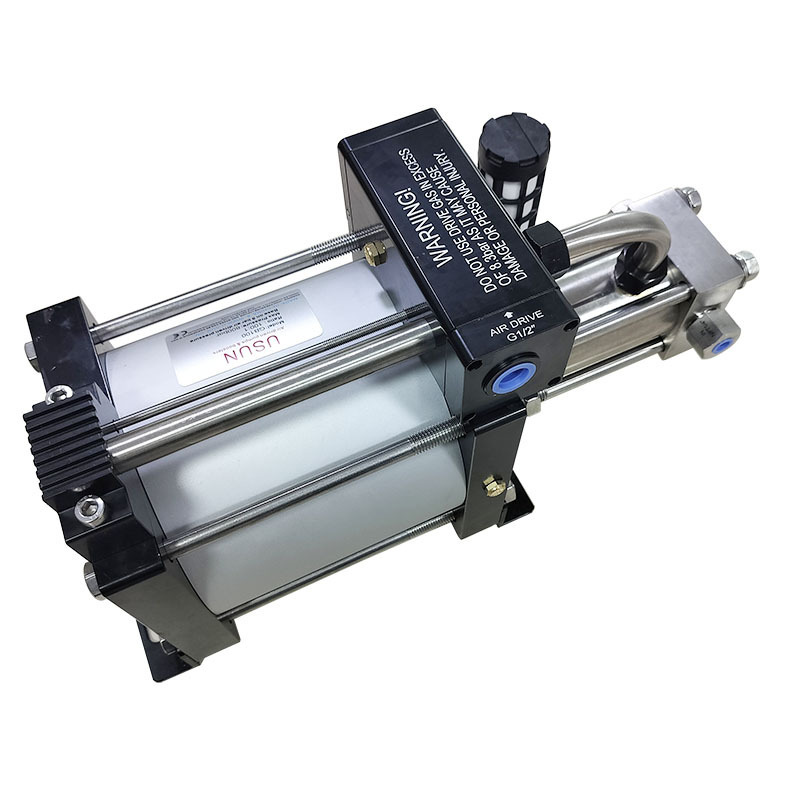

Pneumatic driven oxygen booster

-

Drive air range:

-

Compressed air of 3-10 Bar

-

Driven piston diameter:

-

160MM

Quick Details

-

Application:

-

Machining

-

Pressure:

-

High Pressure

-

Voltage:

-

None

-

Warranty:

-

1 year

-

Brand Name:

-

USUN

-

Model Number:

-

GB40

-

Place of Origin:

-

Guangdong, China

-

Horsepower:

-

None

-

Cable Length:

-

None

-

Outlet Size:

-

None

-

Power:

-

None

-

motor:

-

None

-

Material:

-

Stainless steel Cap and High pressure chamber

-

Pump Type:

-

Horizontal or Vertical installation

-

Product name:

-

Pneumatic driven oxygen booster

-

Drive air range:

-

Compressed air of 3-10 Bar

-

Driven piston diameter:

-

160MM

WHY CHOOSE OUR PUMP?

This brochure introduces pneumatic driven gas/Hydraulic boosters and Complete booster system.

These gas booster pump offer a flexible and efficient source for delivering high pressure gases.

1 . Oxygen or High Purity cleaning : Our booster are noted for their cleaniness and can handle pure gases such as

oxygen without risk of any contamination.We will use customized lubricants for oxygen and also clean it with ultrosonice cleaner

2 . High Flow rates at High pressure : W hen High flow rates at high pressure are needed ,the booster

can charge a receiver to an even higher pressure level ,thus storing a volume of gas aviable for rapid release at a constant

pressure through a pressure reducing valve

3.Cost savings: Most Industrial gases are commonly delivered at pressure of 2000-2600 Psi in steel cylinders .If the

Gas is to be used well bellow the supply pressure ,the pressurized supply is easily piped and controlled to the point of use

with simple valving .However,if the end user requires the gas to be used at higher pressure then the supply it will have to be

boosted gas.Gas booster can untilize all the gas from a supply source such as cylinder and boost the gas to whatever

pressure and flows are required by the application thus untilizing all the gas volume from the supply source .

Usun Model:GB40 150-300 Bar output air driven nitrogen/Helium/Argon/butane gas booster pump for filling gas cylinder

Application : Nitrogen filling stations ,charging high pressure gas cylinders and receivers . Gas assisted plastic injection

molding Hydraulic accumulator charging ,Components testing ,Automotive hoses and component gas testing ,biogas charging and pressure tank vessel leakage testing

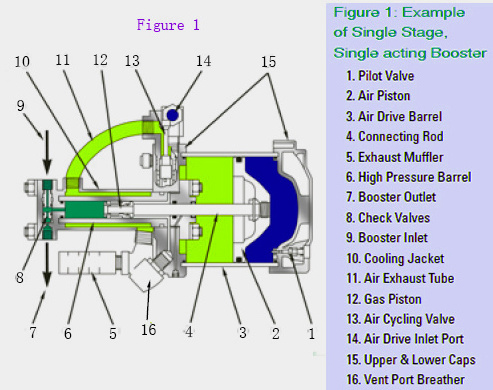

Gas Booster Product Configuration

Single Acting,single stage boosters are the smallest amd lightest with pressure up to Maximum 900 Bar .

Double acting,Single stage provides twice the delivery of a single acting ,single stage booster .

Two stage models are avaible for high gas compression ratios

| Item Number |

GB40 150-300 Bar output air driven nitrogen/helium/argon/butane gas booster pump

|

|

| Action type |

Single air driven,single

action |

|

| Dealing with air source | Dry and clean air filtered regulator with size port of G1/2'' | |

| lubrication | Yes and Non-lubrication for oxygen gas | |

| Operating temperature | -4 to 65 degrees for air driven section and Maximum 115 degress for high pressure gas barrel | |

|

Theory of operation |

The gas booster consist of a large reciprcating air driven piston directly and coupled by a connecting rod to small area gas piston.The gas piston operates in a high pressure gas barrel section and each gas barrel end contains high pressure inlet and outlet check valves | |

| Air pressure range | Compressed air 3-8 Bar | |

| Suitable gases for pump |

Nitrogen,Helium,Breathing air ,Carbon dioxide ,Argon ,Neon and oxygen gas . Noted : liquified gases ( Propane ,Co2 ,Halons) Can be boosted in a liquid and gas in controlled applications |

|

| Installation | Any |

Product features

1. Realiable ,Easy to Maintain ,compact and robust

2. No heat,flame or spark risk

3. Infinitely variable cycling speed and output

4. Air driven Models do not require electrical connection ,easy to apply automatic controls

5. No limit or adverse affect to contineous stop/start applications

6.Seals system designed for long working life,No airline lubricated required

7.Built-in coupling system (Most models) and suitable for most gases boosting

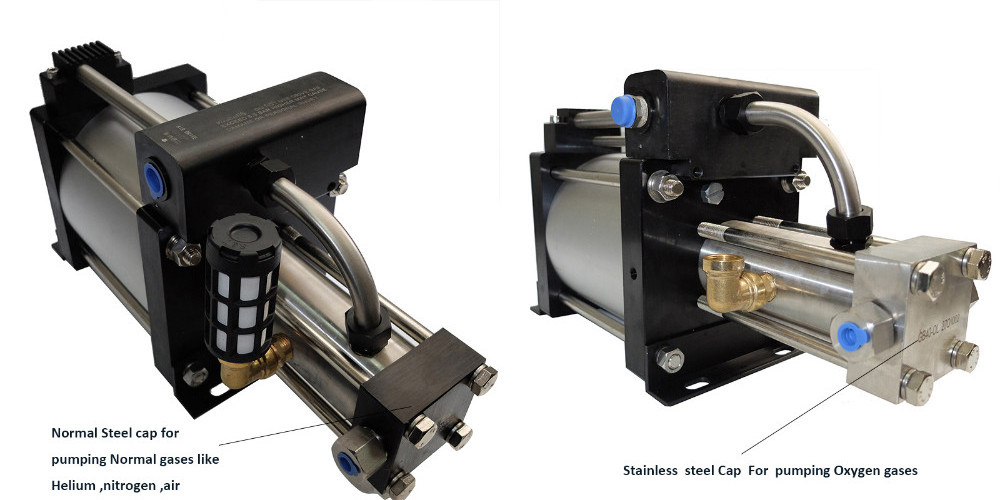

Main manufacturer difference for oxygen pump and Normal gas pump

Main technical parameter

| Model | Pressure ratio | Minimum inlet pressure PI(Bar) | Maximum Outlet pressure PO(Bar) | Outlet pressure formula PO | Inlet port size | Outlet porst size |

Maximum Flow rate L/min= 6 Bar |

| GB02 | 2:1 | 0 | 16.6 | 2PA | PT1/2'' | PT1/2'' | 412@PI=6 |

| GB04 | 4:1 | 1.2 | 33.2 | 4PA | PT1/2'' | PT1/2'' | 354@PI=6 |

| GB05T | 5:1 | 1.7 | 41.5 | 5PA+PI | PT1/2'' | PT1/2'' | 672@PI=6 |

| GB07 | 7:1 | 3.4 | 56 | 7PA | PT3/8'' | PT3/8'' | 252@PI=6 |

| GB08T | 8:1 | 3.4 | 64 | 8PA+PI | PT3/8'' | PT3/8'' | 362@PI=6 |

| GB10 | 10:1 | 3.4 | 80 | 10PA | PT3/8'' | PT3/8'' | 196@PI=6 |

| GB15 | 15:1 | 3.4 | 105 | 15PA | PT3/8'' | PT3/8'' | 164@PI=6 |

| GB25 | 25:1 | 7.5 | 200 | 25PA | PT1/4'' | PT1/4'' | 91@PI=6 |

|

GB40

|

40:1 | 12 | 320 | 40PA | PT1/4'' | PT1/4'' | 56@pi=6 |

| GB60 | 60:1 | 21 | 480 | 60PA | PT1/4'' | PT1/4'' | 72@PI=6 |

| GB100 | 100:1 | 30 | 800 | 100PA | PT1/4'' | PT1/4'' | 45@pi=6 |

| GB130 | 130:1 | 45 | 900 | 130PA | PT1/4'' | PT1/4'' | 28@PI=6 |

PA= Air driven pressure PI=Inlet pressure Po=Outlet pressure

Those data is theoretical and it is just for reference .

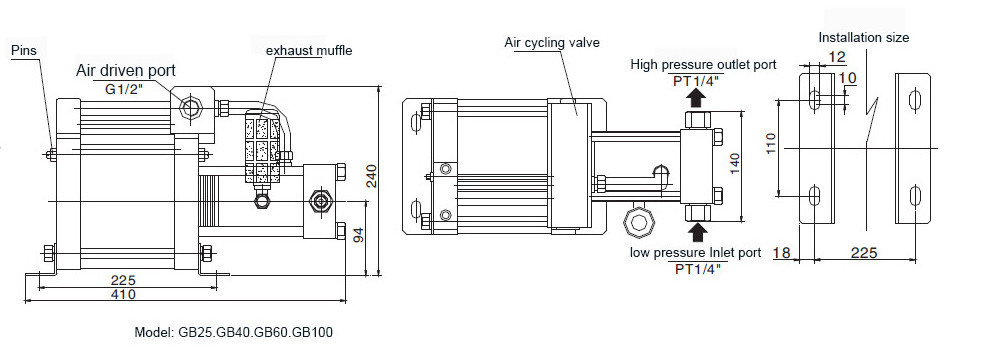

Product outview drawing

Product Gas flow chart

Shipping

| By sea | C heapest but longest option 18~30 days by sea delivery for mass shipment |

| By air | More expensive than sea delivery, But cheaper than express 5~7 days by air to airport. |

| By express | door to door service,the fastest and most expensive one, 3~5 day for DHL /Fedex /UPS/TNT express |