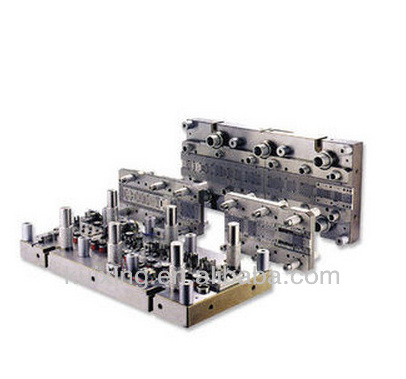

Shanghai KUIXIN Electronic Technology Co., Ltd (former KUIXING) was established in 2001, is a professional modern company integrating the design and manufacture of injection molds, injection processing, painting, silk screen printing, pad printing, hot stamping, laser engraving and assembling of automotive accessories, electronic and electrical accessories, instrument accessories, fitness accessories, medical accessories, industrial supplies accessories and daily accessories. The annual production capacity of injection molds more than 250 sets of injection mold processing capacity of 5 million pieces, the business area mainly covers exports and domestic. The company has more than 80 employees, about 30 professional technicians, and the whole company covers an area of 6000 square meters.

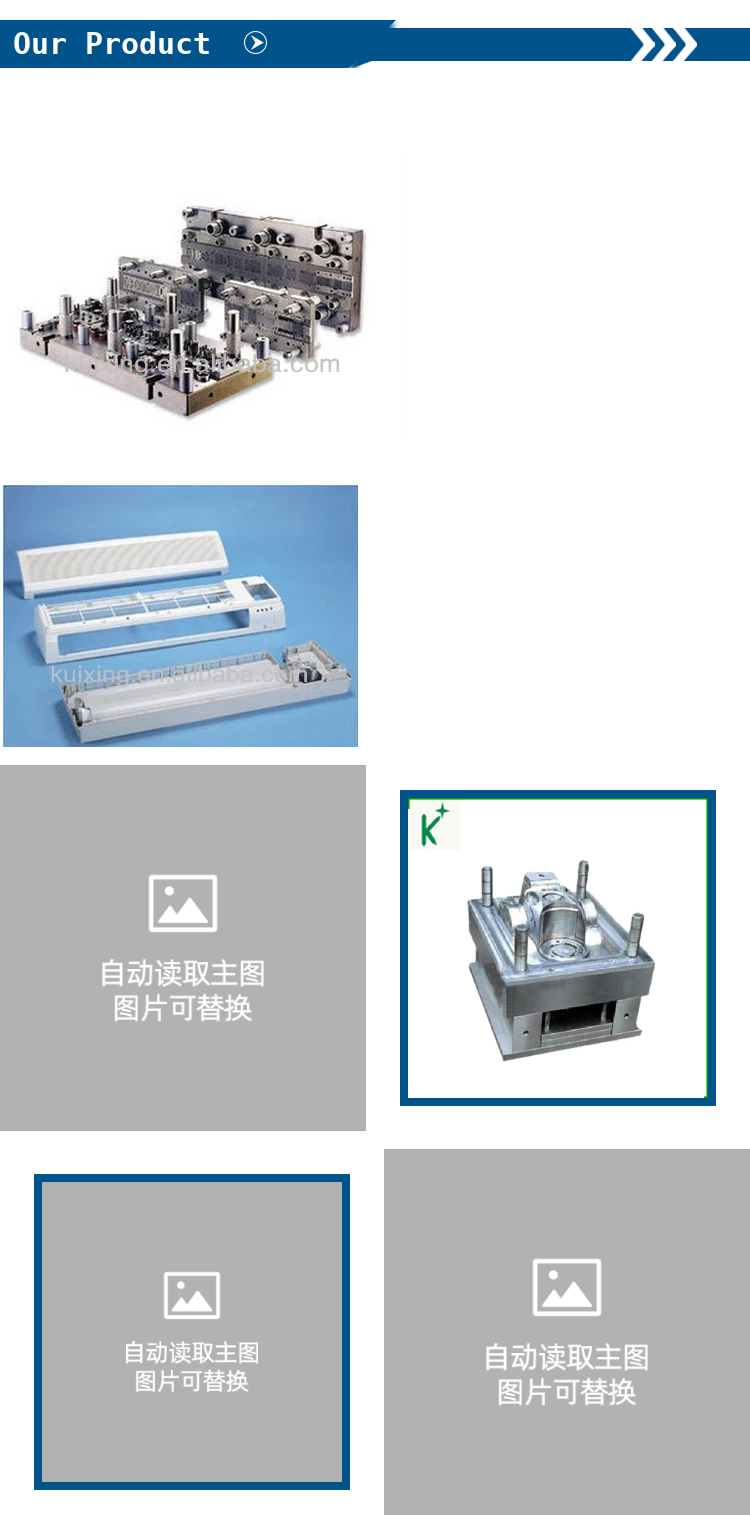

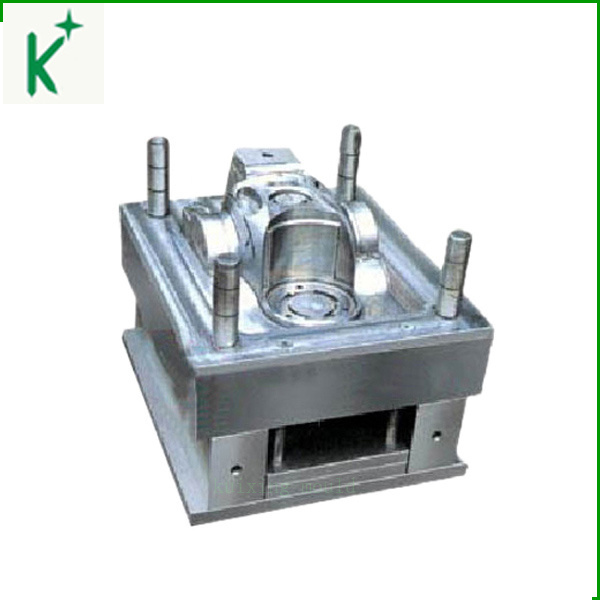

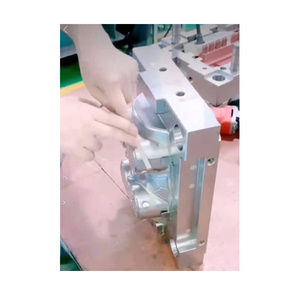

At present, Shanghai Kuixing has CNC numerical control machining, high-speed engraving and milling machine, mirror spark machine, Shadick spark machine and other types of mold production equipment and secondary yuan, three yuan professional testing equipment. At the same time also has a variety of models of Haitian and Zhenxiong injection molding machine (injection molding machine tonnage from 600 tons to 50 tons, etc.), dust-free paint spraying line, screen printing machine, pad printing machine, hot stamping machine and other professional processing equipment dozens of units. The company's mold design and development using UG/CAD/CAM/CAE operating system, the establishment of internal and external network system, to achieve the product from the idea to the finished product transformation.

The printing and painting equipments of Shanghai Kuixing are: UV painting line, silk screen printing machine, pad printing machine, hot stamping machine, ultrasonic welding machine, etc. The workshop is a 100,000 class dust-free and purified workshop. Various kinds of professional manufacturing equipment for the enterprise's rapid development has laid a good foundation. In order to ensure the quality of products, the company strictly according to ISO9001:2015 quality management system for management. Quixing's main service targets are: automotive parts manufacturers, home appliance manufacturers, IT manufacturers, fitness equipment manufacturers, medical equipment manufacturers, instrumentation equipment manufacturers, manufacturers of daily-use and industrial products and other related products of the major production plants. Indirectly serve the automobile, electronic parts industry leaders, such as automotive parts, electronics and notebook computer manufacturers supporting processing.

Shanghai Kuixing has a high-quality experienced management team, adhering to a new business philosophy and management mechanism. With the quality, excellent service and good reputation, and many enterprises and relations. Adhering to the "service, quality zero defect" policy, Quixing will continue to carry forward the "professionalism, integrity, pioneering, innovative" spirit of enterprise, to "people quality control, process control, quality stability, customer satisfaction The company will continue to carry forward the enterprise spirit of "professionalism, integrity, pioneering and innovation", and with the tenet of "human quality control, process control, stable quality and customer satisfaction", it will continue to carry out business reforms and management innovations to enhance the overall competitiveness, cohesion and innovation of the enterprise to serve the society.

At present, Shanghai Kuixing has CNC numerical control machining, high-speed engraving and milling machine, mirror spark machine, Shadick spark machine and other types of mold production equipment and secondary yuan, three yuan professional testing equipment. At the same time also has a variety of models of Haitian and Zhenxiong injection molding machine (injection molding machine tonnage from 600 tons to 50 tons, etc.), dust-free paint spraying line, screen printing machine, pad printing machine, hot stamping machine and other professional processing equipment dozens of units. The company's mold design and development using UG/CAD/CAM/CAE operating system, the establishment of internal and external network system, to achieve the product from the idea to the finished product transformation.

The printing and painting equipments of Shanghai Kuixing are: UV painting line, silk screen printing machine, pad printing machine, hot stamping machine, ultrasonic welding machine, etc. The workshop is a 100,000 class dust-free and purified workshop. Various kinds of professional manufacturing equipment for the enterprise's rapid development has laid a good foundation. In order to ensure the quality of products, the company strictly according to ISO9001:2015 quality management system for management. Quixing's main service targets are: automotive parts manufacturers, home appliance manufacturers, IT manufacturers, fitness equipment manufacturers, medical equipment manufacturers, instrumentation equipment manufacturers, manufacturers of daily-use and industrial products and other related products of the major production plants. Indirectly serve the automobile, electronic parts industry leaders, such as automotive parts, electronics and notebook computer manufacturers supporting processing.

Shanghai Kuixing has a high-quality experienced management team, adhering to a new business philosophy and management mechanism. With the quality, excellent service and good reputation, and many enterprises and relations. Adhering to the "service, quality zero defect" policy, Quixing will continue to carry forward the "professionalism, integrity, pioneering, innovative" spirit of enterprise, to "people quality control, process control, quality stability, customer satisfaction The company will continue to carry forward the enterprise spirit of "professionalism, integrity, pioneering and innovation", and with the tenet of "human quality control, process control, stable quality and customer satisfaction", it will continue to carry out business reforms and management innovations to enhance the overall competitiveness, cohesion and innovation of the enterprise to serve the society.