- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

ACCORDING TO CUSTOMER REQUIREMENT

-

Power:

-

ACCORDING TO CUSTOMER REQUIREMENT

-

Dimension(L*W*H):

-

ACCORDING TO THE CAPACITY

-

Weight:

-

ACCORDING THE CAPACITY TO

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Type:

-

Grain Processing Equipment

-

Certificate:

-

ISO9001:2008 certificate

-

Quality:

-

European standard quality

-

Processing Types:

-

60ton wheat plant

-

Project:

-

design,manufacture,sale and install machines

-

Machinery:

-

roller mill,plansifter,dampener

-

Feature:

-

high effiency/low cost

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

Egypt

-

Certification:

-

ISO

Quick Details

-

Applicable Industries:

-

ROLLER MILL

-

Brand Name:

-

HBA

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

ACCORDING TO CUSTOMER REQUIREMENT

-

Power:

-

ACCORDING TO CUSTOMER REQUIREMENT

-

Dimension(L*W*H):

-

ACCORDING TO THE CAPACITY

-

Weight:

-

ACCORDING THE CAPACITY TO

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Type:

-

Grain Processing Equipment

-

Certificate:

-

ISO9001:2008 certificate

-

Quality:

-

European standard quality

-

Processing Types:

-

60ton wheat plant

-

Project:

-

design,manufacture,sale and install machines

-

Machinery:

-

roller mill,plansifter,dampener

-

Feature:

-

high effiency/low cost

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

Egypt

-

Certification:

-

ISO

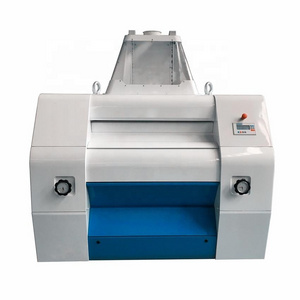

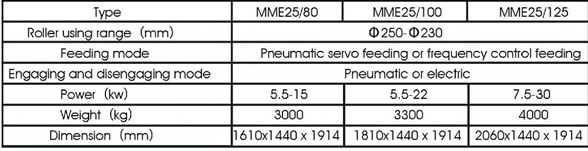

Pneumatic roller mill

The roller mill is the main equipment of flour mill. Depending on a pair of grinding rollers,which have different speeds and rotate oppositely,wheat endosperm is peeled from bran coat and rolled into flour via squeezing,cutting,peeling and scraping.There are two sets of independent transmission systems of feeding and grinding for each roller mill.The different systems have different functions during the working process.

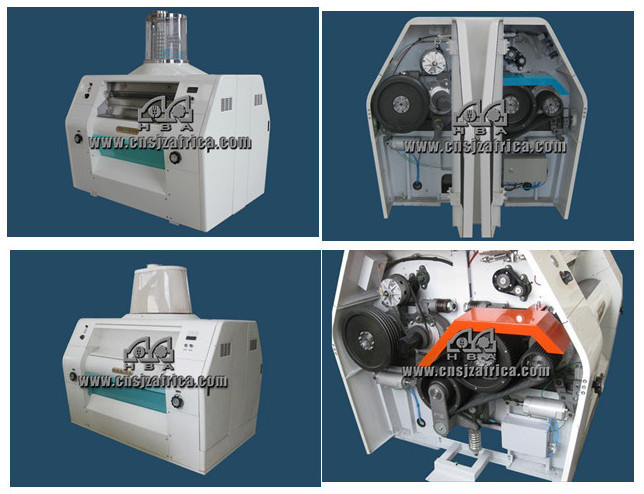

Installed pneumatic Roller Mill

Upper enclosed housing in welded steel construction

.

With two grinding units horizontally arranged, one on both roller mill sides, each equipped with power-integrated bearing packs and vibration absorbers. Self aligning roller bearings

Four built-in grinding rolls of high grade centrifugal cast, dynamically balanced, prepared for water cooling.

Our factory

PLC controlling system

1. In 1~5 months after start of production, we will arrange the related professionals should assist and instruct the production and operation at the site.

2. The warranty period is 12 months after the date of acceptance.

3. In the warranty period, when receiving the notification (telephone) for servi ce sup ply requested by the buyer, we will reply within 4 hours, and meanwhile assign expe rienc ed technicians to arrive at the site within one week to provide service for the buyer.