- Product Details

- {{item.text}}

Quick Details

-

Rated Duty Cycle:

-

98%

-

Max. Welding Thickness:

-

0.2mm

-

Dimensions:

-

438*280*329mm

-

Usage:

-

Ultrasonic Metal Welder Pouch Cell Welding Machine

-

Voltage:

-

220

-

Power (kW):

-

1.2

-

Weight (KG):

-

50 KG

-

Ultrasonic Metal Welder:

-

Ultrasonic Metal Welder Pouch Cell Welding Machine

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Ultrasonic Metal Welder Pouch Cell Welding Machine

-

Rated Capacity:

-

98%

-

Rated Duty Cycle:

-

98%

-

Max. Welding Thickness:

-

0.2mm

-

Dimensions:

-

438*280*329mm

-

Usage:

-

Ultrasonic Metal Welder Pouch Cell Welding Machine

-

Voltage:

-

220

-

Power (kW):

-

1.2

-

Weight (KG):

-

50 KG

-

Ultrasonic Metal Welder:

-

Ultrasonic Metal Welder Pouch Cell Welding Machine

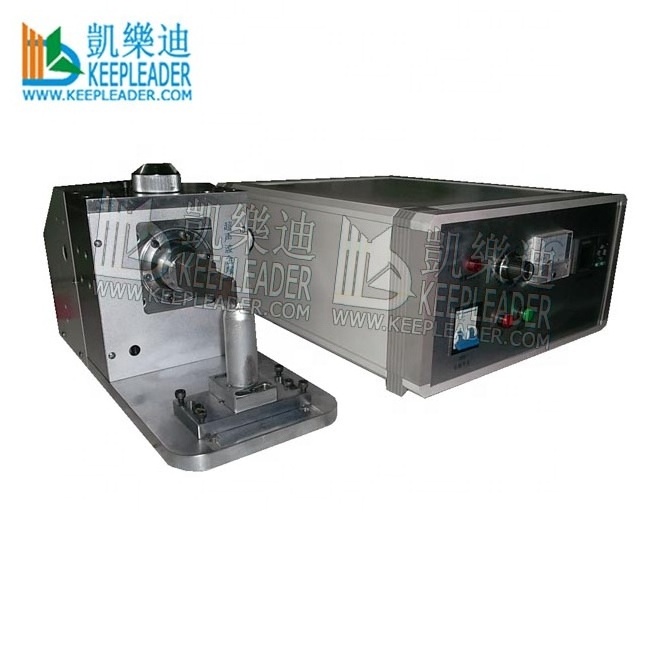

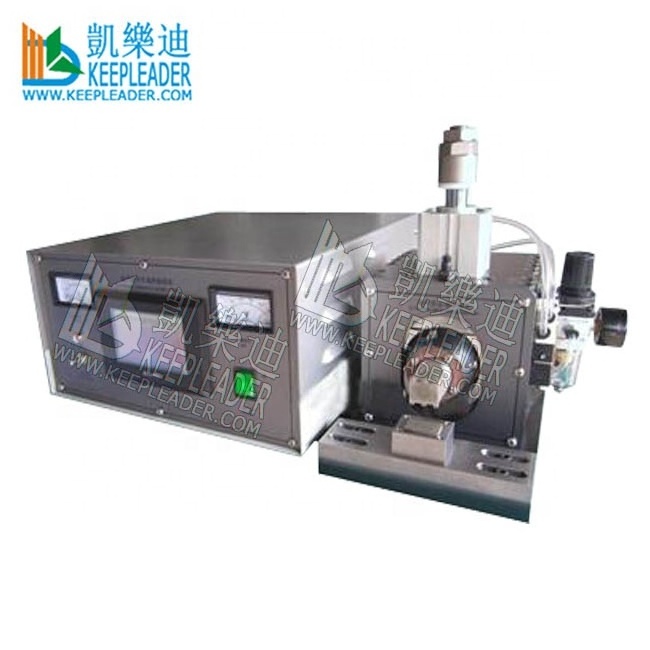

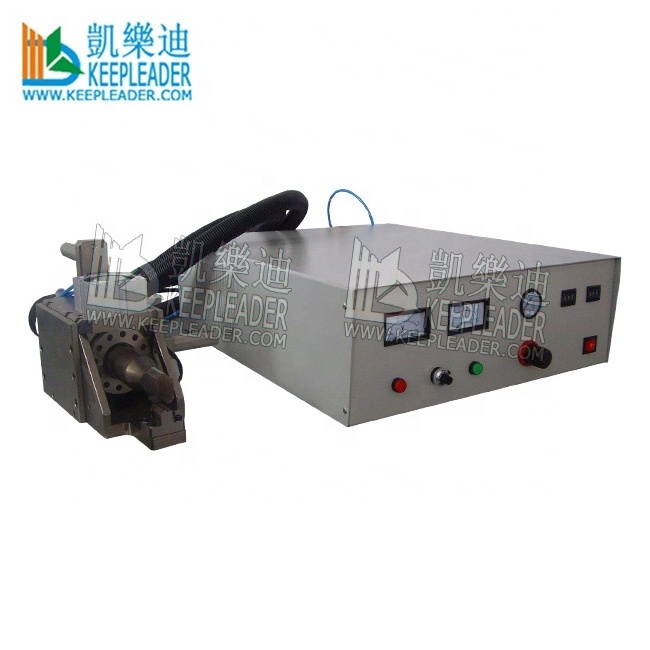

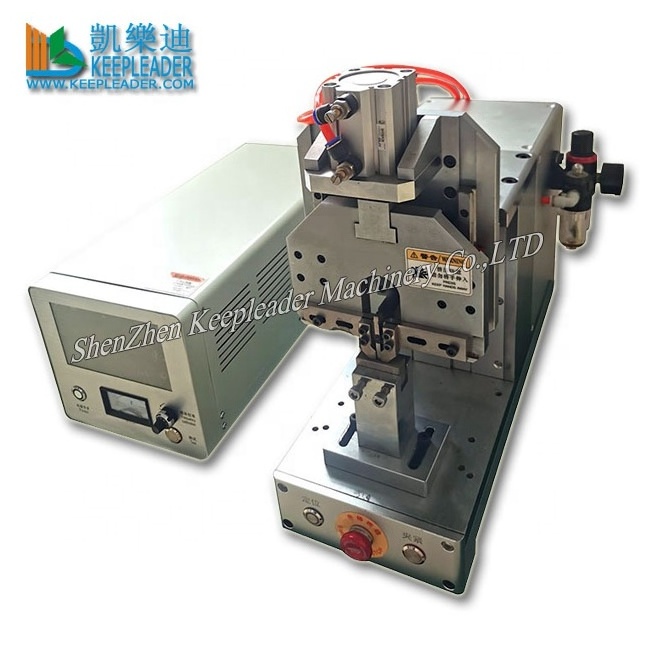

Ultrasonic Metal Welder Pouch Cell Welding Machine

Ultrasonic Metal Welder Pouch Cell Welding Machine takes application of batteries’electrodes bonding, in the whole processing schedules, the foil-to-tab weld is needed for gather all the anode and cathode foils inside the cell and join them to tabs which exit the cell casing allowing the cell’s energy to be transferred to an external source, there are two foil-to-bag welds in each cell, and hundreds of cells in a typical large format lithium-ion battery pack, because of the series and parallel connections, one failure n a foil-to-tab joint will compromise the output of the entire pack, therefore, a robust joining process is required to meet the joint requirements, such as satisfactory joint strength, low electric resistance joint, and minimum inter-metallic layers in joining dissimilar materials; Ultrasonic Metal Welder Pouch Cell Welding Machine tales valuation for this particular application, ultrasonic vibration rubbing bonding is capable of welding similar and dissimilar combination of battery-related materials such as copper, aluminum, and nickel, ultrasonic vibration, typically 20khz, 25khz, and 40khz, are used to rub tab-to-foils’ layer together under pressure, the scrubbing action breaks off oxide and contamination on the surface and break down surface asperities creating two smooth, clean metal surfaces, once these contact under moderate heat and pressure, a weld is formed

|

Principle of metal ultrasonic welding machine |

|

|

Ultrasonic Metal Welder Pouch Cell Welding Machine is applied in Battery industries, the ultrasonic frequency is 20-40khz, ultrasonic energy is generated by high-frequency mechanical vibration, which is applied on the surface of welding parts in welding area under pressure (3kg-5kgs), the same metal or dissimilar metal of non-ferrous can be welded without heating and current, the only mechanical vibration is only repeating between the welding parts to form a solid combination |

|

|

Character |

|

|

Adopt advanced technology from USA, Microprocessor control, automatic frequency tuning, automatic current checking and phase frequency LED display keep the machine visible in operation and regulation Imported components, good performance in energy output Overcurrent protection and soft start can keep the machine safe High quality mould/Tooling can extend lifespan Easy installation and operation |

|

|

Parameter |

|

|

Name |

|

|

Model |

KLM-1224 |

|

Ultrasonic power |

1.2kw |

|

Ultrasonic frequency |

24khz |

|

Air supply |

7-8bat (kg/cm*2) |

|

Power supply |

220VAC,50HZ |

|

Maximum working pressure |

6kg/ cm*2 |

|

Minimum working pressure |

0.3kg/cm*2 |

|

Inlet connection |

Quick coupling |

|

Welding time |

0.01s-10s (adjustable) |

|

Squeeze time |

0.02s-1s (adjustable) |

|

Frequency display |

00.0000-24.000hz |

|

Power option |

300w,600w,1200w |

|

Automatic frequency tuning |

±2HZ |

|

Protection system |

Inside power tube self-protection 60+ |

|

EMI/EMC |

qualified |

|

Cylinder diameter |

50mm |

|

Cylinder stroke |

20mm |

|

Welding head |

Fillet welding |

|

Size of welding spot |

3*4/3.5/4*5*/5*5MM |

|

Welding material |

AL+NI/CU+NI/AL+AL |

|

Welding thickness |

0.1-2mm |

|

Overall size |

438*280*329mm |

|

Net weight |

40kgs |

|

Packing size |

210*50*2000mm |

MFR: KEEPLEADER™ have modified and designed Ultrasonic Metal Welder Pouch Cell Welding Machine for our customers’ unique and special requirements, please contact KEEPLEADER™ for updated details

Welding ability

10~25 layers 0.09~0.012 copper foil+ 0.1~0.3mm Ni or nickel-clad copper tab welding with size: 4*6, 4*8, 4*10, 4*12mm or customized

10~25 layers 0.09~0.012 aluminum foil+ 0.1~0.3mm Al tab welding with size: size: 4*6, 4*8, 4*10, 4*12mm or customized

0.2mm Al belt+ 0.2mm Ni belt or Nickel-clad copper wrapping welding with size: 4*6, 4*8, 4*10, 4*12mm customized

2~4 layers 0.2mm Al tab or 2~4 layers 0.2mm Ni tab weld with size: 4*6, 4*12mm customized

Ultrasonic Metal Welder Pouch Cell Welding Machine achieve prominent advantages because of its salient characteristics in metal bonding performance, likely,No.1: ultra fast: the entire process lasts for mere split seconds;No.2: precise: ultrasonic welding is spot-on, a vast number of welding parameters ensure precise and reproducible results, this is particularly important for welding the smallest metal parts, for example, in battery electronic connection of aluminum foil layers-to-Nickel tab of cathode and copper foil layers-to-Nickel tab of anode;No.3:cost-efficient: no other additives such as solder or other additional gas or chemical agent are used, ultrasonic bonding is sold-state joining in molecular scale;No.4: Environmentally friendly: very little energy is consumed and not chemicals are used; No.5: characteristic:ultrasonic welding ensures a high degree of strength and excellent electrical conductivity at the joined points;No.6:Gentle: the metals are not damaged or deformed apart from the weld spot;No.7:Safe:No sparks or smoke are generated during ultrasonic welding

Increasing demands of lithium-ion batteries impels the development of Ultrasonic Metal Welder Pouch Cell Welding Machine , joining anodes of copper foils layers-to-tab and cathode of aluminum foils layers-to-tab together requires the best joining technique with long-term process reliability, Ultrasonic Metal Welder Pouch Cell Welding Machine is reliable approach for manufacturing lithium batteries, particularly for pouch cell batteries, keepleader, we manufacture a full range of ultrasonic metal welding systems for bonding conductive materials in applications such as wire splicing, wire termination, battery tabbing, cable processing, seam welding, tube sealing and more

ABOUT PRODUCT

Customized design; Safe and convenient operation

ABOUT FACTORY

Comprehensive management process, leading technology and service team

EXPERIENCE

Internationalization of business process; Rich experience of Non-standard design

AFTERSERVICE

Uniform standard with special difference for each, Professional and Experienced service

MARKET

Yearly 30% Market share increased, One-to-one service

SERVICE PROCESS AT

KEEPLEADER™

the clients offer information of the workpieces being welded (eg: picture, materials, sizes, requirements, etc) if have samples, it’s better to send

KEEPLEADER™

some samples to perform the welding test, if can be welded, we provide offer sheet, once confirmed, sign a contract, the clients paid the deposit,

KEEPLEADER™

start equipment building, after passing the acceptance, and receive the balance payment,

KEEPLEADER™

delivery the device to clients

Ultrasonic Metal Welder Pouch Cell Welding Machine has tutorial video and user manual